Mar . 05, 2025 02:38 Back to list

3d curved welded wire mesh fence panel

Selecting the best welded sheep fence panel is crucial for farmers and livestock managers who aim to ensure safety, durability, and cost-effectiveness in their fencing solutions. Having operated in the agricultural sector for over a decade, I find that not all fence panels are made equal. Some stand out due to their resilience under harsh weather conditions and their efficiency in keeping the flock secure. My experience reveals the nuanced specifics that differentiate quality welded sheep fence panels from inferior options.

For installation, it is imperative to employ professionals who understand the nuances of terrain and livestock behavior. Incorrect installation could negate the benefits of even the best materials, compromising security, and incurring unnecessary costs. Partnering with experts not only ensures precision but also provides invaluable insights based on site-specific parameters. Customer testimonials serve as a testament to a product’s authenticity and reliability. Before finalizing any purchase, seeking reviews from fellow farmers or community forums can reveal hidden strengths or weaknesses. Personally, feedback has often unveiled critical flaws I might have otherwise overlooked in specifications charts. The environmental impact of manufacturing and maintaining sheep fence panels cannot be understated. Opting for eco-friendly options, such as sustainably sourced steel or production methods that minimize carbon footprints, aligns with global conservation goals bolstering the brand's market image as well. Finally, cost must be evaluated not just by the initial price but in terms of long-term value. A slightly higher upfront cost can lead to substantial savings over the fence's lifespan, reducing maintenance frequency and ensuring consistency in livestock containment. In conclusion, choosing the best welded sheep fence panel requires a comprehensive approach, blending material science with practical field insights. As the agricultural industry evolves, making informed decisions about infrastructure like fencing not only secures livestock but enhances operational efficiency and sustainability. The ideal panel balances functionality, durability, and cost, ensuring farmers can focus on thriving livestock without the constant worry of containment issues.

For installation, it is imperative to employ professionals who understand the nuances of terrain and livestock behavior. Incorrect installation could negate the benefits of even the best materials, compromising security, and incurring unnecessary costs. Partnering with experts not only ensures precision but also provides invaluable insights based on site-specific parameters. Customer testimonials serve as a testament to a product’s authenticity and reliability. Before finalizing any purchase, seeking reviews from fellow farmers or community forums can reveal hidden strengths or weaknesses. Personally, feedback has often unveiled critical flaws I might have otherwise overlooked in specifications charts. The environmental impact of manufacturing and maintaining sheep fence panels cannot be understated. Opting for eco-friendly options, such as sustainably sourced steel or production methods that minimize carbon footprints, aligns with global conservation goals bolstering the brand's market image as well. Finally, cost must be evaluated not just by the initial price but in terms of long-term value. A slightly higher upfront cost can lead to substantial savings over the fence's lifespan, reducing maintenance frequency and ensuring consistency in livestock containment. In conclusion, choosing the best welded sheep fence panel requires a comprehensive approach, blending material science with practical field insights. As the agricultural industry evolves, making informed decisions about infrastructure like fencing not only secures livestock but enhances operational efficiency and sustainability. The ideal panel balances functionality, durability, and cost, ensuring farmers can focus on thriving livestock without the constant worry of containment issues.

Latest news

-

Powder Coated Double Wire Mesh Fence-Anping County Shengxin Metal Products Co., Ltd.

NewsAug.02,2025

-

Powder Coated Double Wire Mesh Fence | Anping County Shengxin Metal Products Co., Ltd

NewsAug.02,2025

-

Powder Coated Double Wire Mesh Fence for Germany Market-Anping County Shengxin Metal Products Co., Ltd|Durability, Aesthetics, Compliance

NewsAug.02,2025

-

Powder Coated Double Wire Mesh Fence-Anping County Shengxin Metal Products Co., Ltd.|Durability&Compliance

NewsAug.02,2025

-

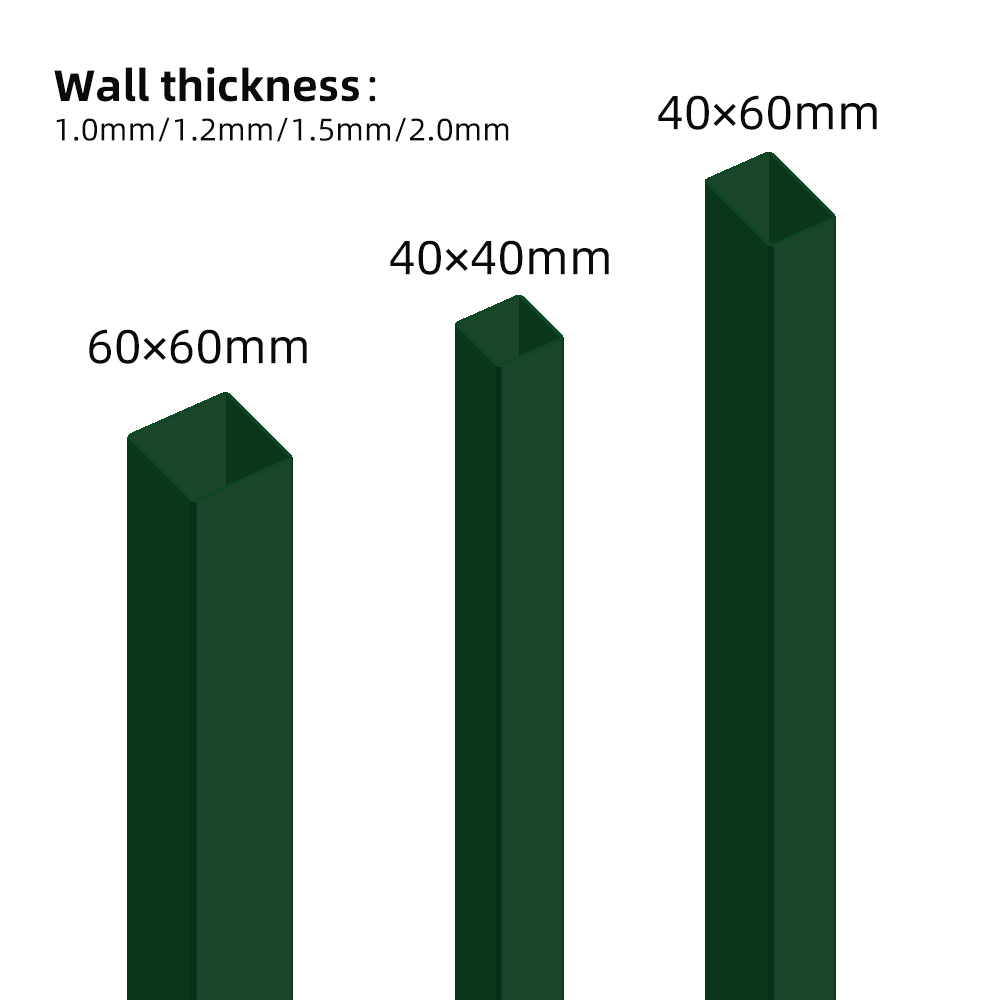

Powder Coated Square Fence Posts | Removable Decorative Metal

NewsAug.02,2025

-

Premium ODM 7' Security Fence - High-Security & Durable

NewsAug.01,2025