Jun . 13, 2024 00:14 Back to list

Metal fence panel manufacturing factories

Exploring the World of Metal Fence Panel Factories

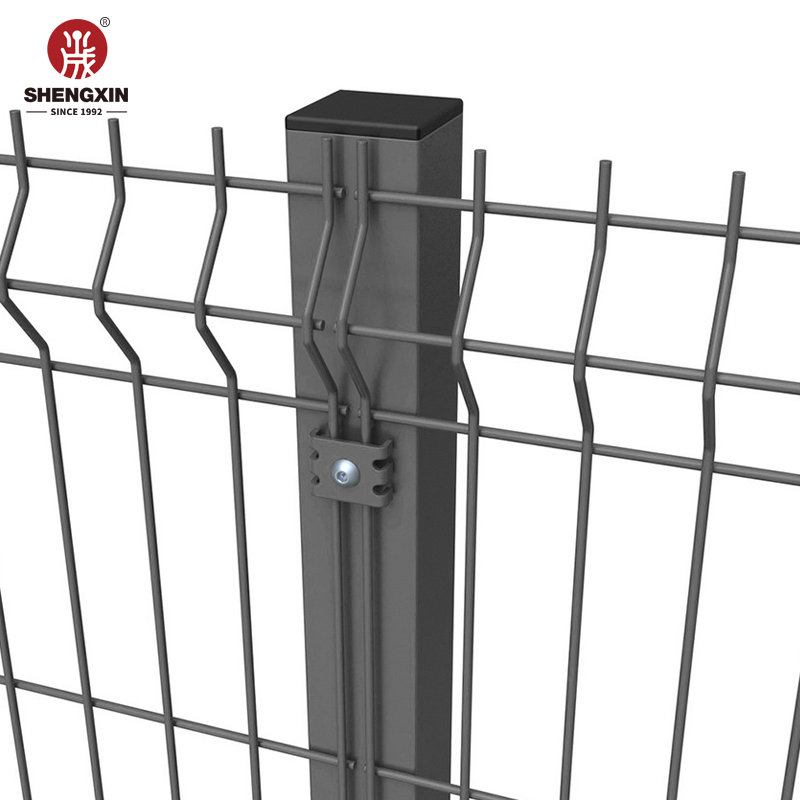

In today's modern construction and landscaping industry, metal fence panels have become an increasingly popular choice due to their durability, strength, and aesthetic appeal. These versatile panels are manufactured in specialized facilities known as metal fence panel factories, where cutting-edge technology meets skilled craftsmanship to create high-quality fencing solutions.

Metal fence panel factories are typically large-scale industrial units equipped with state-of-the-art machinery and tools. They operate on a comprehensive production process that begins with the selection of raw materials, primarily steel or aluminum, renowned for their resilience against harsh weather conditions and potential vandalism. The material is then subjected to rigorous quality checks to ensure its integrity before entering the production line.

The first step in the manufacturing process involves cutting the metal sheets into the desired panel sizes. This is done using precision CNC (Computer Numerical Control) machines that guarantee accuracy and consistency. Following this, the panels undergo bending and shaping to form the distinctive fence designs, whether it be traditional, ornamental, or contemporary styles.

Once the basic shape is achieved, the panels are treated with a protective coating to enhance their resistance to corrosion and rust. This could include galvanization, where the metal is coated with zinc, or powder coating, which adds a durable and colorfast finish. The choice of coating not only extends the lifespan of the fence but also contributes to its aesthetic appeal.

After the coating process, the panels move on to assembly, where additional features such as posts, gates, and hardware are attached

After the coating process, the panels move on to assembly, where additional features such as posts, gates, and hardware are attached After the coating process, the panels move on to assembly, where additional features such as posts, gates, and hardware are attached

After the coating process, the panels move on to assembly, where additional features such as posts, gates, and hardware are attached

After the coating process, the panels move on to assembly, where additional features such as posts, gates, and hardware are attached

After the coating process, the panels move on to assembly, where additional features such as posts, gates, and hardware are attached fence panel metal factories. Skilled technicians ensure that each component fits perfectly, providing a secure and seamless installation experience. Quality control teams then inspect every finished product for any defects, ensuring that only the highest standard panels leave the factory.

Metal fence panel factories also prioritize customization to cater to diverse customer needs. Whether it's a residential property seeking privacy, a commercial establishment requiring security, or an ornamental touch for a garden, these factories can tailor-make panels to specific dimensions, designs, and colors.

Moreover, these factories often adhere to strict environmental standards, recycling waste materials and implementing energy-efficient practices to minimize their carbon footprint. Their commitment to sustainability aligns with the growing demand for eco-friendly construction solutions.

In conclusion, metal fence panel factories play a pivotal role in the production of robust and visually appealing fencing options. Their advanced manufacturing processes, coupled with a focus on customization and sustainability, make them indispensable contributors to the construction sector. As the world continues to seek durable and sustainable fencing alternatives, these factories stand ready to innovate and meet the evolving needs of customers worldwide.

fence panel metal factories. Skilled technicians ensure that each component fits perfectly, providing a secure and seamless installation experience. Quality control teams then inspect every finished product for any defects, ensuring that only the highest standard panels leave the factory.

Metal fence panel factories also prioritize customization to cater to diverse customer needs. Whether it's a residential property seeking privacy, a commercial establishment requiring security, or an ornamental touch for a garden, these factories can tailor-make panels to specific dimensions, designs, and colors.

Moreover, these factories often adhere to strict environmental standards, recycling waste materials and implementing energy-efficient practices to minimize their carbon footprint. Their commitment to sustainability aligns with the growing demand for eco-friendly construction solutions.

In conclusion, metal fence panel factories play a pivotal role in the production of robust and visually appealing fencing options. Their advanced manufacturing processes, coupled with a focus on customization and sustainability, make them indispensable contributors to the construction sector. As the world continues to seek durable and sustainable fencing alternatives, these factories stand ready to innovate and meet the evolving needs of customers worldwide.

After the coating process, the panels move on to assembly, where additional features such as posts, gates, and hardware are attached

After the coating process, the panels move on to assembly, where additional features such as posts, gates, and hardware are attached

After the coating process, the panels move on to assembly, where additional features such as posts, gates, and hardware are attached

After the coating process, the panels move on to assembly, where additional features such as posts, gates, and hardware are attached fence panel metal factories. Skilled technicians ensure that each component fits perfectly, providing a secure and seamless installation experience. Quality control teams then inspect every finished product for any defects, ensuring that only the highest standard panels leave the factory.

Metal fence panel factories also prioritize customization to cater to diverse customer needs. Whether it's a residential property seeking privacy, a commercial establishment requiring security, or an ornamental touch for a garden, these factories can tailor-make panels to specific dimensions, designs, and colors.

Moreover, these factories often adhere to strict environmental standards, recycling waste materials and implementing energy-efficient practices to minimize their carbon footprint. Their commitment to sustainability aligns with the growing demand for eco-friendly construction solutions.

In conclusion, metal fence panel factories play a pivotal role in the production of robust and visually appealing fencing options. Their advanced manufacturing processes, coupled with a focus on customization and sustainability, make them indispensable contributors to the construction sector. As the world continues to seek durable and sustainable fencing alternatives, these factories stand ready to innovate and meet the evolving needs of customers worldwide.

fence panel metal factories. Skilled technicians ensure that each component fits perfectly, providing a secure and seamless installation experience. Quality control teams then inspect every finished product for any defects, ensuring that only the highest standard panels leave the factory.

Metal fence panel factories also prioritize customization to cater to diverse customer needs. Whether it's a residential property seeking privacy, a commercial establishment requiring security, or an ornamental touch for a garden, these factories can tailor-make panels to specific dimensions, designs, and colors.

Moreover, these factories often adhere to strict environmental standards, recycling waste materials and implementing energy-efficient practices to minimize their carbon footprint. Their commitment to sustainability aligns with the growing demand for eco-friendly construction solutions.

In conclusion, metal fence panel factories play a pivotal role in the production of robust and visually appealing fencing options. Their advanced manufacturing processes, coupled with a focus on customization and sustainability, make them indispensable contributors to the construction sector. As the world continues to seek durable and sustainable fencing alternatives, these factories stand ready to innovate and meet the evolving needs of customers worldwide. Latest news

-

Coated Galvanized Steel Wire Mesh Fencing Panels | Durability & Protection

NewsAug.04,2025

-

Powder Coated Double Wire Mesh Fence-Anping County Shengxin Metal Products Co., Ltd

NewsAug.03,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd

NewsAug.03,2025

-

Power Coated 358 Anti Climb Mesh Fence for Airports

NewsAug.03,2025

-

Powder Coated Double Wire Mesh Fence-Anping County Shengxin Metal Products Co., Ltd.

NewsAug.02,2025

-

Powder Coated Double Wire Mesh Fence | Anping County Shengxin Metal Products Co., Ltd

NewsAug.02,2025