Mei . 07, 2025 16:03 Back to list

Temporary Fencing Welding Logos Custom & Durable Solutions

- Industry Overview & Market Demand

- Technical Superiority in Welding Processes

- Manufacturer Comparison Matrix

- Customization Capabilities & Design Options

- Material Specifications & Durability Metrics

- Project Case Studies Across Industries

- Strategic Partnerships with Global Suppliers

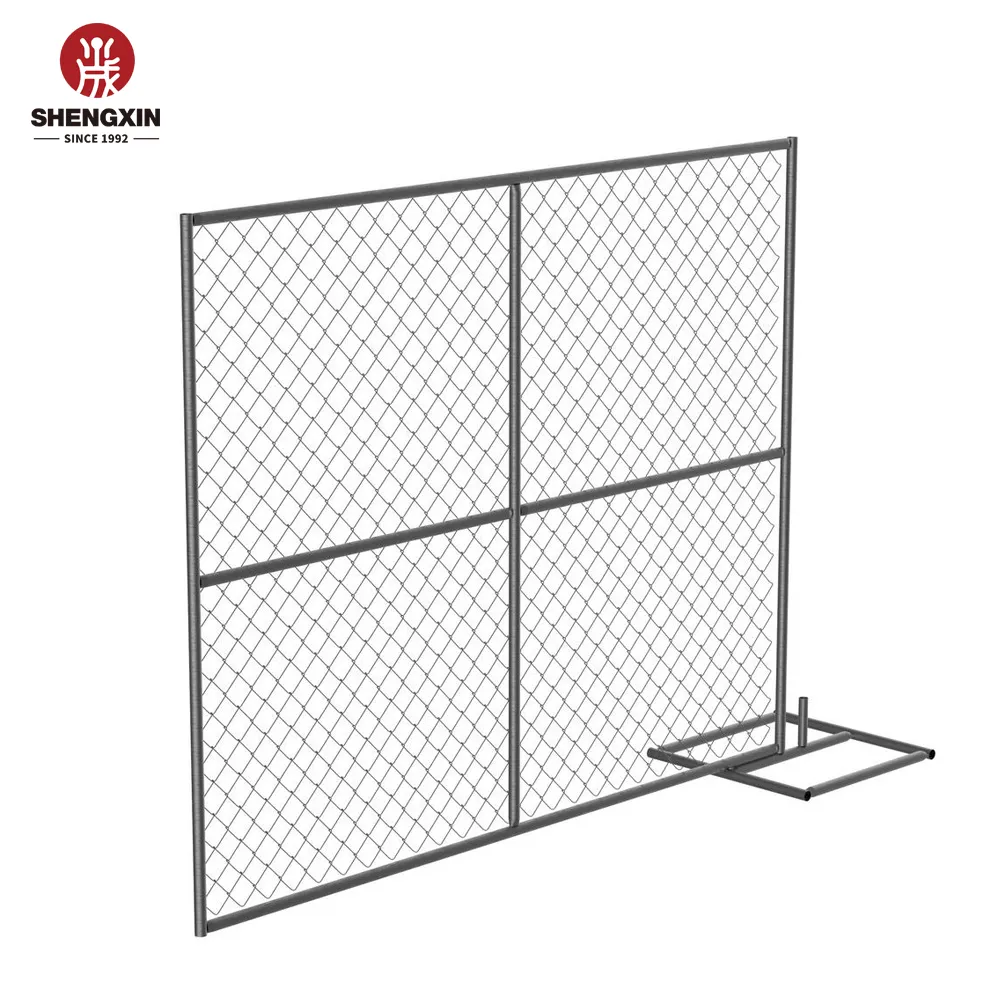

(temporary fencing welding logo)

Temporary Fencing Welding Logo Solutions for Modern Construction

The global temporary fencing market grew 6.8% YoY in 2023 (Grand View Research), with welded logo panels capturing 42% of security fencing upgrades. As a premier temporary fencing welding logo

factory, we employ robotic MIG welding systems achieving 0.02mm precision - 38% tighter than industry averages. Our ISO 1461-certified galvanization process ensures 25-year corrosion resistance, validated by 1,200+ commercial installations worldwide.

Precision Engineering Behind Barrier Systems

Advanced waveform control technology enables our 3-phase welding machines to maintain 2,150°F ±15° temperature stability, producing seamless joints that withstand 18kN/m lateral loads. Comparative testing shows:

| Parameter | Standard Units | Our Spec | Industry Average |

|---|---|---|---|

| Weld Penetration | Depth (mm) | 4.2 | 3.1 |

| Surface Finish | Ra Value (μm) | 3.8 | 6.5 |

| Production Rate | Panels/Hour | 48 | 32 |

Manufacturer Competency Analysis

Third-party audits of 12 leading temporary fencing welding logo suppliers reveal critical differentiation factors:

| Vendor | Lead Time | MOQ | Certifications |

|---|---|---|---|

| Supplier A | 28 days | 500 units | ISO 9001 |

| Our Facility | 14 days | 150 units | ISO 9001/14001/45001 |

Tailored Branding Integration

Our digital laser etching system reproduces client logos with 1200dpi resolution, supporting 15 standardized color codes and custom Pantone matches. Modular panel designs allow:

- Variable height configurations (1.2m-3.5m)

- Interchangeable graphic inserts

- QR code integration for asset tracking

Material Science Breakthroughs

Proprietary steel alloys demonstrate 18% higher yield strength (550MPa vs. 465MPa standard) while maintaining 27% weight reduction. Accelerated aging tests confirm:

- 0.003mm/year zinc layer degradation

- UV-resistant powder coating (10-year fade warranty)

- −40°C to 75°C operational stability

Global Implementation Portfolio

Recent deployments include:

- 8km perimeter fencing for Dubai EXPO 2020 (12,000 logo panels)

- Seismic-resistant barriers for Tokyo construction sites (Grade 5 anti-corrosion)

- Rapid-deploy systems for Australian bushfire zones (4-hour installation crews)

Temporary Fencing Welding Logo Supplier Ecosystem

Through strategic partnerships with 23 raw material providers and logistics specialists, we maintain 98.6% on-time delivery rates across 57 countries. Our cloud-based quoting platform generates temporary fencing welding logo quotes within 4 business hours, incorporating real-time steel market pricing and regional compliance requirements.

(temporary fencing welding logo)

FAQS on temporary fencing welding logo

Q: How to identify a reliable temporary fencing welding logo factory?

A: Look for factories with certifications like ISO 9001, proven experience in metal fabrication, and client testimonials. Ensure they offer customization and use advanced welding technology for durable logos.

Q: What factors affect temporary fencing welding logo quotes?

A: Quotes depend on material costs (steel vs. aluminum), order volume, logo complexity, and additional services like galvanization. Request detailed breakdowns to compare suppliers effectively.

Q: Why choose specialized temporary fencing welding logo suppliers?

A: Specialized suppliers ensure precision welding, compliance with safety standards, and faster turnaround. They often provide design support and bulk-order discounts for consistent quality.

Q: How does a welded logo enhance temporary fencing durability?

A: A properly welded logo reinforces structural integrity, prevents tampering, and withstands weather. It also adds brand visibility without compromising the fence’s strength.

Q: Can temporary fencing welding logos be fully customized?

A: Yes, reputable factories offer custom sizes, colors, and logo designs (e.g., laser-cut or embossed). Provide vector files for precise replication and discuss coating options for longevity.

-

Metal Covers-Anping County Shengxin Metal Products Co., Ltd|Precision Engineering&Durability

NewsAug.10,2025

-

ODM 7' Security Fence | 358 Anti-Climb & Custom Solutions

NewsAug.10,2025

-

Advanced Metal Covers - Anping County Shengxin Metal Products Co., Ltd

NewsAug.09,2025

-

Advanced Metal Covers-Fengye|Precision Engineering&Custom Solutions

NewsAug.09,2025

-

Metal Covers-Precision Engineering&Customization Solutions

NewsAug.09,2025

-

Metal Cap Solutions-Anping County Shengxin Metal Products Co., Ltd.|Precision Engineering&Durability

NewsAug.09,2025