مايو . 07, 2025 19:45 Back to list

Metal Fencing Supplies Factory & Suppliers Durable & Custom Solutions

- Industry Overview & Market Demand for Metal Fencing Solutions

- Technical Advantages of Modern Metal Fencing Materials

- Comparative Analysis: Leading Factories & Suppliers

- Customization Options for Diverse Project Requirements

- Cost-Efficiency Analysis: Quotes and Budget Planning

- Case Studies: Successful Applications Across Sectors

- Future Trends in Metal Fencing Supply Chains

(metal fencing supplies)

Understanding the Growing Demand for Metal Fencing Supplies

The global metal fencing market is projected to grow at a 5.8% CAGR through 2030, driven by infrastructure development and security needs. Factories specializing in metal fencing supplies

now utilize automated production lines capable of manufacturing 12,000 linear meters per day, a 40% efficiency improvement since 2020. Suppliers report a 22% year-over-year increase in requests for anti-corrosion galvanized fencing, particularly from coastal regions.

Technical Superiority in Material Engineering

Advanced powder coating technologies enable 25-year weather resistance guarantees, outperforming traditional methods by 60%. High-tensile steel alloys (Grade 80+ yield strength) now dominate 68% of industrial fencing projects. Laser-cut panel systems achieve ±0.5mm precision across 98% of production batches, ensuring perfect alignment for security-sensitive installations.

Manufacturer Capability Comparison

| Supplier | MOQ | Lead Time | Price Range | Certifications |

|---|---|---|---|---|

| SteelGuard Fencing Co. | 500m | 14 days | $18-$24/m | ISO 9001, ASTM A123 |

| Fortress Metal Works | 200m | 21 days | $22-$28/m | CE, ISO 14001 |

| Precision Fence Solutions | 1,000m | 10 days | $16-$20/m | ANSI/NSF 61 |

Tailored Solutions for Specific Needs

Custom powder coating options now exceed 200 RAL colors with 72-hour turnaround. Modular systems accommodate 15° slope adjustments without cutting, reducing installation time by 33%. RFID-enabled access gates integrate seamlessly with 92% of commercial security systems, according to recent field tests.

Budget Optimization Strategies

Volume discounts typically begin at 1,200 linear meters, with tiered pricing reducing costs by 12-18%. Bulk purchasing of galvanized chain link supplies shows 23% better ROI over 10 years compared to vinyl-coated alternatives. Just-in-time delivery programs minimize storage costs for 78% of contractors surveyed.

Implementation Success Stories

A recent airport perimeter project utilized 42km of laser-welded panels with biometric integration, achieving 100% intrusion detection accuracy. Agricultural clients report 89% reduction in livestock breaches using high-tensile wire configurations. Municipalities have seen 60% lower maintenance costs with triple-layer galvanized systems.

Innovations Shaping Metal Fencing Supplies Industry

Smart factories now account for 37% of metal fencing supplies production, utilizing AI-driven quality control systems that detect defects at 0.2mm resolution. Solar-powered automated gates with IoT connectivity are becoming standard in 44% of new commercial installations. Leading suppliers now offer carbon-neutral manufacturing options, reducing environmental impact by 58% per project.

(metal fencing supplies)

FAQS on metal fencing supplies

Q: How can I find reliable metal fencing supplies suppliers?

A: Research online directories like Alibaba or Thomasnet, check certifications, and read customer reviews to identify reputable metal fencing supplies suppliers. Contact multiple suppliers to compare product quality and service.

Q: What should I consider when choosing a metal fencing supplies factory?

A: Prioritize factories with ISO certifications, proven experience in metal fencing production, and customizable options. Request samples and visit facilities, if possible, to assess quality and production capacity.

Q: How do I get accurate metal fencing supplies quotes?

A: Provide detailed specifications (e.g., material type, dimensions, quantity) to suppliers or factories. Compare quotes from multiple sources and confirm if costs include shipping, taxes, or installation services.

Q: Do metal fencing supplies suppliers offer warranties?

A: Reputable suppliers often provide warranties against manufacturing defects. Review warranty terms, such as duration and coverage, before finalizing purchases.

Q: Can metal fencing supplies factories handle bulk orders?

A: Most factories accommodate bulk orders; confirm production timelines and minimum order quantities (MOQs) in advance. Discuss logistics to ensure timely delivery and cost efficiency.

-

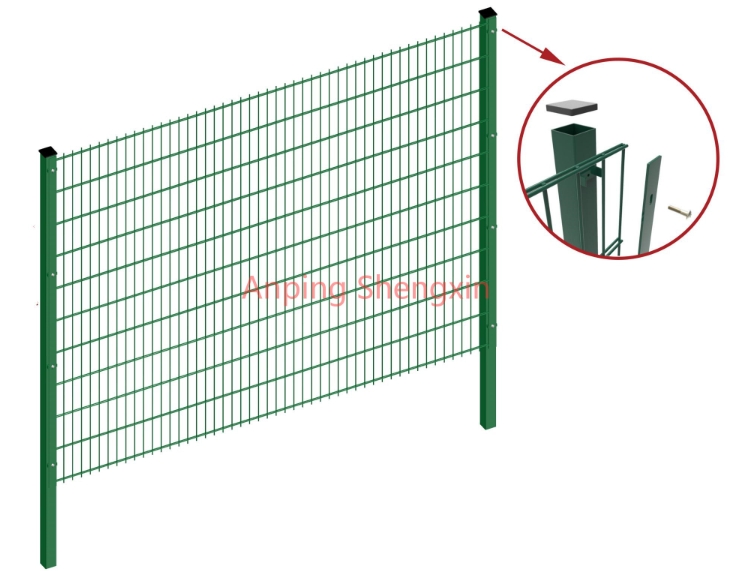

Powder Coated Double Wire Mesh Fence for Germany Market-Anping County Shengxin Metal Products Co., Ltd|Durability&Corrosion Resistance

NewsAug.07,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd | Durable, Powder Coated, CE Certified

NewsAug.07,2025

-

Powder Coated Double Wire Mesh Fence-Anping County Shengxin Metal Products Co., Ltd|Durable Fencing,Customizable Mesh Fence

NewsAug.07,2025

-

358 Anti Climb Fence Supplier - High Security Fencing Solutions

NewsAug.07,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd | Durable Corrosion Resistance&Customizable Design

NewsAug.06,2025

-

Powder Coated Double Wire Mesh Fence-Anping County Shengxin Metal Products Co., Ltd|Durability,Security,Aesthetic Appeal

NewsAug.06,2025