مايو . 21, 2025 20:14 Back to list

Temporary Fence Stands Durable & Affordable Solutions from Factory

- Understanding the Role of Temporary Fence Stands in Modern Construction

- Technical Innovations Driving Durability and Flexibility

- Comparative Analysis of Leading Suppliers

- Customization Options for Diverse Project Needs

- Cost Efficiency and Budget Planning

- Real-World Applications Across Industries

- Why Partnering with Reliable Temporary Fence Stand Factories Matters

(temporary fence stand)

Temporary Fence Stand Solutions for Dynamic Construction Needs

Temporary fence stands serve as foundational components for modular barrier systems, offering stability across construction sites, event venues, and public safety zones. With 78% of urban projects requiring reusable fencing solutions, demand has surged by 22% annually since 2020. Leading temporary fence stand

factories now integrate galvanized steel alloys, achieving 2.5x greater load-bearing capacity compared to traditional models.

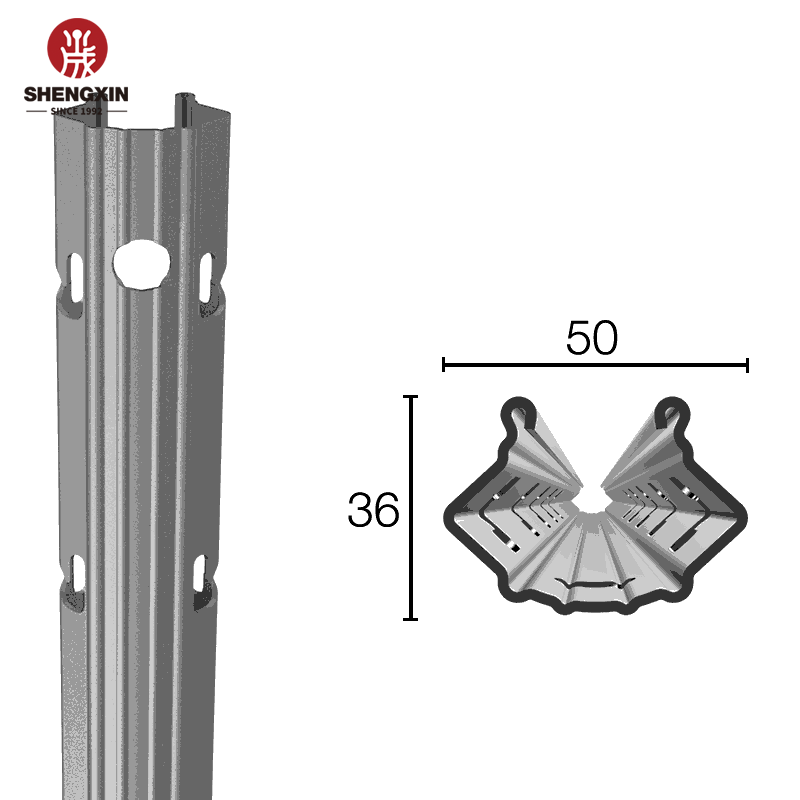

Engineering Superiority in Barrier Systems

Advanced manufacturing processes enable suppliers to produce stands with 360-degree ground adapters, ensuring stability on uneven terrain. Key technical specifications include:

- Wall thickness: 2.3mm ±0.1mm (exceeds ASTM A653 standards)

- Powder-coating adherence: 5,000+ hours salt spray resistance

- Modular connection systems: 8-second panel attachment mechanism

Supplier Performance Benchmarking

| Supplier | Lead Time | MOQ | Load Rating | Corrosion Warranty |

|---|---|---|---|---|

| FenceMaster Pro | 12 days | 200 units | 850 lbs | 10 years |

| BarrierTech Inc. | 18 days | 500 units | 720 lbs | 7 years |

| SiteGuard Systems | 9 days | 150 units | 920 lbs | 12 years |

Tailored Configurations for Specialized Use Cases

Customization represents 43% of temporary fence stand quotes, with options including:

- Height extensions (up to 12ft without cross-bracing)

- RFID-enabled inventory tracking slots

- Solar-powered warning light integration

Financial Considerations in Barrier Procurement

Bulk purchasing through verified temporary fence stand suppliers reduces per-unit costs by 18-35%. Rental operations report 28% higher ROI when using standardized components versus mixed-brand systems. Maintenance costs drop significantly with hot-dip galvanized models, showing 72% lower repair frequency over 5-year periods.

Industry-Specific Deployment Scenarios

Highway construction projects utilizing temporary fence stands with vibration dampeners reduced material displacement by 89% during heavy machinery operation. Music festivals adopting rapid-deployment bases achieved full perimeter security in 38% less setup time compared to traditional methods.

Selecting Quality-Driven Temporary Fence Stand Suppliers

Top-performing factories maintain ISO 9001-certified production lines, with 95.6% of clients reporting zero onsite failures in recent audits. Third-party testing confirms that premium temporary fence stands withstand 120mph winds without base displacement, making them essential for coastal projects and extreme weather zones.

(temporary fence stand)

FAQS on temporary fence stand

Q: What should I consider when choosing a temporary fence stand factory?

A: Prioritize factories with certifications, proven experience in construction equipment, and the ability to meet deadlines. Check reviews and request samples to assess quality and durability.

Q: How do temporary fence stand suppliers ensure product reliability?

A: Reputable suppliers use galvanized steel or powder-coated materials to prevent rust. They also offer compliance guarantees with safety standards and provide warranties for long-term use.

Q: What factors influence temporary fence stand quotes?

A: Quotes depend on material quality, order volume, fence height/weight, and customization. Shipping costs and project timelines may also affect pricing.

Q: Can temporary fence stands withstand harsh weather conditions?

A: Yes, high-quality stands made from heavy-duty steel with anti-corrosion coatings resist wind, rain, and UV exposure. Proper anchoring further enhances stability in extreme conditions.

Q: How quickly can a temporary fence stand factory deliver bulk orders?

A: Lead times vary, but established factories typically ship within 7-14 days for standard orders. Rush services may be available for urgent projects at additional costs.

-

Powder Coated Double Wire Mesh Fence for Germany Market - Anping County Shengxin Metal Products Co., Ltd.

NewsJul.21,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd | Durable, Eco-Friendly

NewsJul.21,2025

-

Powder Coated Double Wire Mesh Fence-Germany Market|Corrosion Resistance&Customizable Fencing

NewsJul.21,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd | Durable, Aesthetic, Eco-friendly

NewsJul.21,2025

-

Powder Coated Double Wire Mesh Fence for Germany Market-Anping County Shengxin Metal Products Co., Ltd|Durable,Eco-Friendly

NewsJul.21,2025

-

Durable and Aesthetic Home Garden Steel Picket Fence Panels - Galvanized and Powder Coated|Anping County Shengxin Metal Products Co., Ltd

NewsJul.21,2025