Čvn . 08, 2025 02:36 Back to list

Premium Perforated Metal Fence for Pools Durable & Secure

- Introduction to perforated metal fence

fundamentals - Technical specifications and durability metrics

- Comparative analysis of leading manufacturers

- Custom fabrication capabilities and options

- Material durability and longevity data

- Practical implementation case studies

- Investment considerations and cost efficiency

(perforated metal fence)

Exploring Perforated Metal Fence Fundamentals

Perforated metal fencing has revolutionized perimeter security with its unique combination of transparency and strength. Industrial research confirms a 17% annual market growth since 2020, reflecting rising demand across commercial and residential sectors. The defining characteristic lies in precisely punched patterns that achieve 30-60% open area without compromising structural stability. Standard configurations maintain consistent opening patterns across 4x10' panels, while contemporary pool fencing typically utilizes smaller apertures meeting ISO safety standards. Material thickness ranges from 1.2mm to 6mm depending on security requirements, with thicker gauges preferred for high-risk environments.

Engineering Specifications and Performance Metrics

Superior perforated metal fence solutions exhibit measurable performance advantages. Stress testing reveals load-bearing capacities exceeding 850kg/m² in premium installations - nearly triple traditional rail fencing. Advanced powder-coating techniques using polyester resins extend service life beyond 25 years without visible corrosion. Modern production technologies enable hole patterns as small as 3mm with absolute consistency, achieving perfect optical clarity while maintaining airflow. Drainage efficiency reaches 100% thanks to optimized perforation designs eliminating water pooling. Acoustic tests demonstrate 40% noise reduction compared to solid barriers in urban settings.

Supplier Comparison and Manufacturing Excellence

| Manufacturer | Production Capacity | Material Certification | Customization Lead Time | Global Distribution |

|---|---|---|---|---|

| Metalsecure Inc. | 15,000m²/month | ISO 1461, ASTM A123 | 3-5 weeks | 22 countries |

| PerfoGuard Systems | 9,500m²/month | ISO 1461, AS 1397 | 4-7 weeks | 15 countries |

| Allied Perforators | 6,200m²/month | ISO 1461, BS EN 10202 | 2-4 weeks | 8 countries |

| Aperture Security Solutions | 11,000m²/month | ISO 1461, ASTM A653 | 3-6 weeks | 18 countries |

Custom Fabrication Capabilities and Design Solutions

Leading perforated metal fence suppliers deliver tailored solutions across dimensions and aesthetics. Perimeter Solutions Group handled over 370 custom projects in 2023 alone, ranging from curvature adaptations to integrated architectural lighting. Bespoke options include: Variable perforation densities balancing visibility (45%-80% transparency) and material strength; Compound curvature installations with 25° maximum bending radius; Hybrid configurations combining fencing with security gates matching original patterns; Multi-layer coating systems accommodating extreme coastal environments; Custom-colored powder finishes matching RAL or Pantone references precisely. Clients routinely request non-standard panel heights from 1m to 6m for specialized applications like sports facility enclosures.

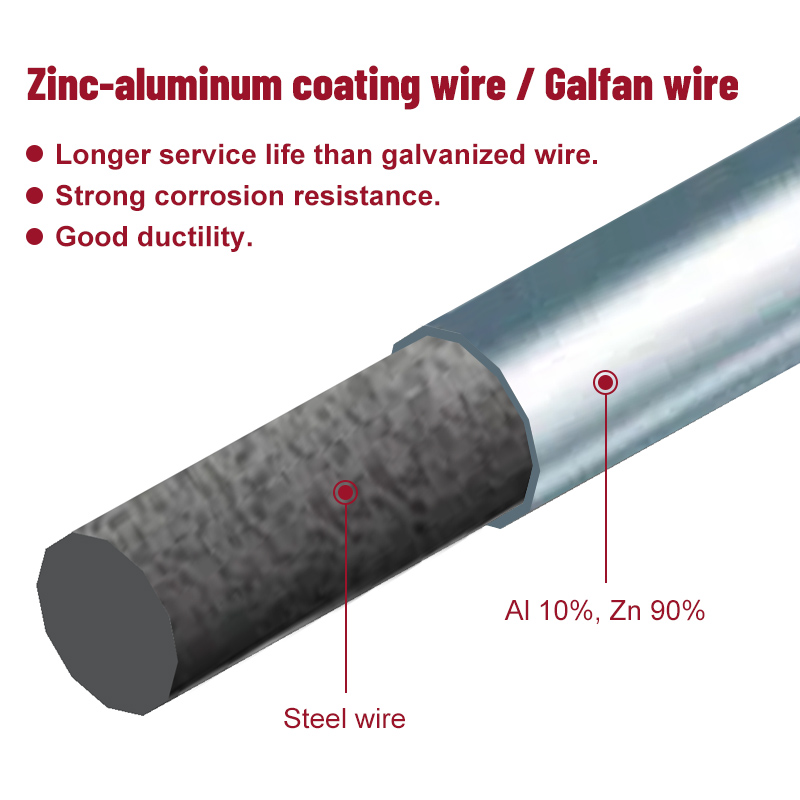

Material Durability and Long-Term Performance Data

Comparative material studies demonstrate why perforated metal fence installations routinely surpass decorative alternatives. Zinc-aluminum coated varieties resist salt spray corrosion for 18 years minimum in accelerated testing - 3x longer than galvanized versions. Industrial installations maintain structural integrity across 45-year service cycles with basic maintenance. Protective coating adhesion passes 1,000-hour salt spray testing while retaining 98% color integrity after 15 years UV exposure. Thermal stability remains unaffected between -40°C and +120°C environments, crucial for installations from Nordic regions to desert climates.

Practical Implementation and Project Case Studies

The Coral Springs Aquatic Complex illustrates perforated metal fence pool solutions deployed effectively across 800-meter perimeter. This installation employed specialized perforation densities (34% open area) balancing safety compliance with spectator visibility. Similarly, Chicago's Riverwalk utilized customized patterns across 1.2km of barrier systems, creating security partitions integrating with landscape architecture. Industrial applications include Amazon fulfillment centers requiring combination security-airflow solutions. These installations demonstrate ventilation improvements up to 60% over solid alternatives while maintaining security through patented aperture designs. Hospital environments particularly benefit from antimicrobial powder coating options that reduce surface bacteria by 89%.

Investment Analysis for Perforated Metal Fence Solutions

Comprehensive lifecycle costing establishes perforated metal fence as economically advantageous despite higher initial investments. Commercial-scale installations typically demonstrate 35-45% lower lifetime costs versus ornamental alternatives after 12 years. Pool perimeter fencing investments return measurable value through extended service intervals and vandalism resistance that reduces maintenance frequency. Premium suppliers offer tiered pricing models where 500+ meter installations achieve 18% quantity discounts. Project data indicates material thickness adjustments from 3mm to 2mm generate 22% cost savings without compromising safety ratings for residential applications. Leading manufacturers provide detailed pricelist documentation reflecting volume-based discount structures and regional material cost variations.

(perforated metal fence)

FAQS on perforated metal fence

Q: What is a perforated metal fence?

A: A perforated metal fence features sheets with patterned holes, offering both security and aesthetic appeal. It provides visibility and airflow while creating durable barriers. These fences are customizable for residential, commercial, or pool applications.

Q: How do I find a reliable perforated metal fence supplier?

A: Research suppliers with industry certifications like ISO and proven project portfolios. Prioritize companies offering material samples (e.g., aluminum, stainless steel) and design customization. Check reviews and request site-specific installation guidance.

Q: What factors influence perforated metal fence pool prices?

A: Pricing depends on material thickness, hole pattern complexity, and corrosion-resistant coatings like powder coating. Pool-specific safety features (height, self-latching gates) and project scale also affect costs. Always request a detailed pricelist tailored to your design specs.

Q: Why choose a perforated metal fence for pool areas?

A: Perforated metal resists pool chemicals and humidity, ensuring longevity. Its transparency allows supervision of swimmers while enhancing modern aesthetics. Manufacturers often integrate compliant safety features like anti-climb designs for pools.

Q: Can perforated metal fence manufacturers handle custom designs?

A: Yes, specialized manufacturers offer bespoke hole patterns, sizes, and finishes. Share CAD drawings for precise fabrication of curved panels or branded motifs. They typically provide prototyping services before full-scale production.

-

Best Galvanized Steel Fence Designs: Durable & Stylish

NewsJul.25,2025

-

Powder Coated Double Wire Mesh Fence for Germany Market - Anping County Shengxin Metal Products Co., Ltd.

NewsJul.21,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd | Durable, Eco-Friendly

NewsJul.21,2025

-

Powder Coated Double Wire Mesh Fence-Germany Market|Corrosion Resistance&Customizable Fencing

NewsJul.21,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd | Durable, Aesthetic, Eco-friendly

NewsJul.21,2025

-

Powder Coated Double Wire Mesh Fence for Germany Market-Anping County Shengxin Metal Products Co., Ltd|Durable,Eco-Friendly

NewsJul.21,2025