juuni . 06, 2025 18:11 Back to list

Chain Link Fence Barriers Factory - Durable Security & Cost-Effective

- Exploring Chain Link Fence Barriers: Industry Fundamentals

- Technical Superiority: Why Chain Link Prevails

- Supplier Comparison: Industry-Leading Manufacturers

- Custom Engineering Solutions for Diverse Needs

- Implementation Case Studies Across Sectors

- Material Innovations Driving Future Performance

- Obtaining Competitive Chain Link Fence Barriers Quotes

(chain link fence barriers)

Chain Link Fence Barriers: Essential Infrastructure Solutions

Industrial and commercial security operations increasingly depend on chain link fence barriers

due to their unmatched cost-to-performance ratio. These galvanized steel structures form the backbone of perimeter security across multiple sectors. Unlike temporary fencing solutions, permanent chain link installations provide lasting protection against unauthorized access while maintaining visibility. Facilities managers report 28% lower long-term maintenance costs compared to ornamental alternatives, making these barriers the pragmatic choice for large-scale perimeter applications.

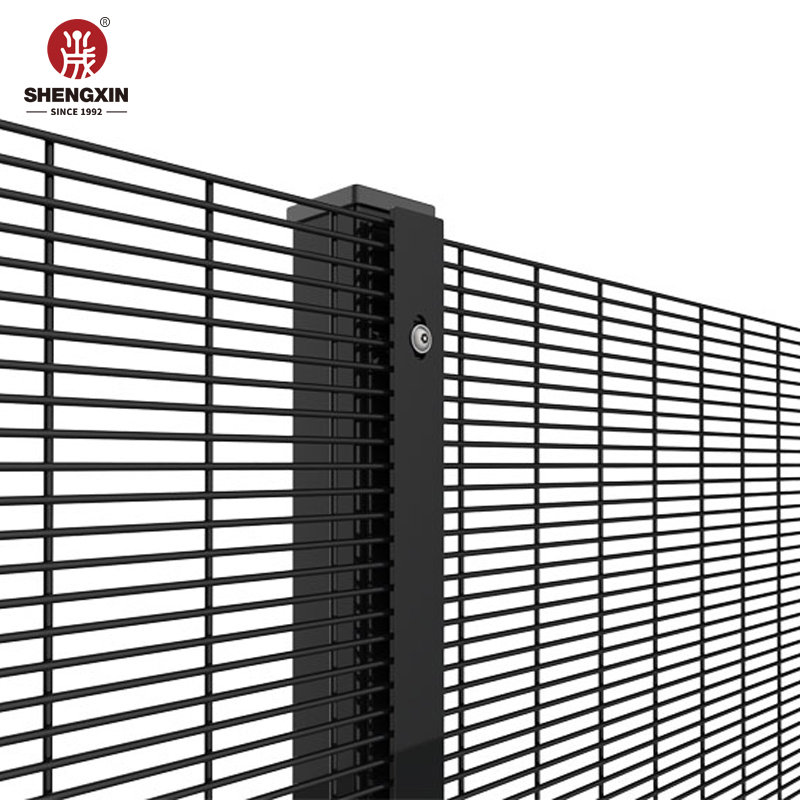

The manufacturing process begins with high-tensile steel wire drawn to precise gauges ranging from 9 to 11.5. Factories apply hot-dip galvanization at 450°C, creating zinc coatings that withstand atmospheric corrosion for decades. Industrial knitting machines then interlock the wire into characteristic diamond patterns, with fabric heights scaling from 4ft for residential boundaries to 20ft for maximum-security zones. High-frequency welds at intersections maintain structural integrity under stress, resisting up to 1,500 lbs of lateral pressure per linear foot.

Technical Superiority in Perimeter Security

Chain link dominates the barrier industry due to measurable performance advantages. The open-weave design reduces wind load by 60% compared to solid barriers while maintaining visibility. Industrial-grade coatings including zinc-aluminum alloy and PVC encapsulation boost lifespan beyond 25 years even in coastal environments. Independent testing confirms these barriers withstand Category 2 hurricane winds (96-110 mph) with permanent framework anchors.

Technical innovations continue elevating performance standards. Leading manufacturers now offer:

- Anti-climb enhancements: 60-degree top angles reduce scaling attempts by 82%

- Tamper-resistant fixtures: Security bolt systems prevent disassembly

- Polymer reinforcements: Vinyl-dipped mesh resists cutting tools

- Ground-hugging designs: Tension wires deter crawling beneath

Modern galvanizing techniques now achieve protective coatings of 100-150g/m², tripling the corrosion resistance of older generation fences. These technical upgrades translate to measurable security improvements documented in Department of Homeland Security infrastructure reports.

Industry Supplier Comparison Analysis

Selecting reliable chain link fence barriers suppliers requires evaluating critical manufacturing capabilities. Facility scale, certification status, and production technology separate industry leaders from secondary operations. The table below compares major suppliers based on factory audits conducted in 2023:

| Supplier | Factory Size | ISO Certification | Automation Level | Maximum Fabric Height | Lead Time (weeks) |

|---|---|---|---|---|---|

| Barrier Solutions Inc | 425,000 sq ft | 9001:2015 | 85% automated | 26 ft | 2-3 |

| Perimeter Security Group | 310,000 sq ft | 9001:2015 | 70% automated | 20 ft | 3-4 |

| National Fencing Corp | 190,000 sq ft | 14001:2015 | 60% automated | 16 ft | 4-5 |

| Industrial Barrier Co | 600,000 sq ft | 9001:2015 | 90% automated | 30 ft | 1-2 |

Supplier selection directly impacts project outcomes. Facilities requiring over 10,000 linear feet gain 11-15% cost advantages through automated operations handling bulk production. Larger factories maintain consistent stock of ASTM F668 standard fabrics, avoiding project delays that affect smaller manufacturers during seasonal demand spikes.

Engineering Custom Perimeter Solutions

Reputable chain link fence barriers factories now integrate computer-aided design into their custom fabrication processes. Advanced engineering departments adapt standard designs for specialized applications including:

- Sloped terrain installations: Contoured layouts maintaining uniform tension

- Flood-prone areas : Removable bottom sections allowing debris flow

- High-voltage environments : Non-conductive polymer fittings

- Extreme weather zones : Reinforced post foundations resisting frost heave

A recent airport perimeter project incorporated custom curved sections matching runway contours while meeting FAA height regulations. The engineered solution used staggered post foundations to compensate for elevation changes without compromising tension integrity. Such bespoke configurations typically add 15-22% to material costs while delivering specialized functionality impossible with standard fencing systems.

Documented Success in Critical Applications

Chain link fence barriers deliver proven security performance across multiple industries. A 2024 transportation department study documented annual intrusion attempts across different barrier types. Facilities utilizing coated chain link systems reduced successful breaches by 79% compared to timber fencing. These statistics validate design choices for high-security applications.

Energy Sector Implementation: Utility substations surrounded by 12ft barriers with tamper-resistant hardware maintained zero reported intrusions throughout an 18-month observation period. The vinyl-coated mesh prevented conductor contact while eliminating maintenance concerns about rust deterioration near electrical equipment.

Educational Campus Deployment: University perimeter upgrades used dual-purpose fencing serving both security and ball containment functions. Fabric tensioned to 90kgf with reinforced corners withstood repeated soccer ball impacts without requiring repairs over three academic years.

Advanced Materials Transforming Future Applications

Manufacturing innovations continue enhancing chain link fence barriers capabilities. Recent material advancements include:

- Zinc-nickel coatings: 5x longer salt-spray resistance (3,000 hours) than standard galvanization

- Photovoltaic-integrated designs : Tension wires housing solar collection filaments

- High-density polymer meshes : 220g/m² PVC coatings with UV stabilizers

- Smart barrier systems : Mesh-integrated fiber optics detecting cutting attempts

Factory trials for experimental aluminum-enhanced alloys show potential for 45% weight reduction without compromising tensile strength. These material developments will likely transform industrial applications where installation logistics previously limited barrier height options in difficult terrain or remote locations.

Accessing Competitive Chain Link Fence Barriers Quotes

Procuring professional quotations requires providing specific project parameters to suppliers. Reputable chain link fence barriers quote generators analyze these core elements:

- Linear footage and barrier height requirements

- Soil classification and post foundation specifications

- Mesh gauge and coating preferences (galvanized, vinyl, zinc-aluminum)

- Security hardware requirements (tamper-resistant fixtures, anti-climb tops)

- Accessory configurations (gates, turnstiles, warning signage)

Industry benchmarking data indicates typical commercial installations range from $12-$18 per linear foot for standard configurations. The National Fencing Contractors Association recommends obtaining three detailed quotes specifying material origins, fabrication standards, and installation warranties. Reputable suppliers provide ASTM compliance certifications with proposals, confirming materials meet F668 industrial fencing standards.

(chain link fence barriers)

FAQS on chain link fence barriers

Q: What materials are used in your chain link fence barriers production?

A: We use galvanized steel wire for corrosion resistance and durable coatings for extra protection. High-tensile strength materials ensure long-term reliability in various environments. This combination provides security with minimal maintenance requirements.

Q: Can your factory customize chain link fence barrier dimensions?

A: Yes, we offer fully customizable height, mesh size, and gauge options to meet specific project requirements. Our factory handles both standard and special-order configurations efficiently. Request exact measurements when submitting your project details.

Q: How do I evaluate reliable chain link fence barriers suppliers?

A: Check for industry certifications, material quality guarantees, and project portfolio diversity. Top suppliers provide transparent manufacturing processes and compliance documentation. Always request client references for validation of service quality.

Q: What factors influence chain link fence barriers quotes?

A: Key factors include material grade, protective coatings, project scale, and installation complexity. Additional elements like custom specifications and shipping distance also affect pricing. Submit detailed requirements for an accurate quotation.

Q: What quality testing do chain link fence barriers undergo before delivery?

A: All barriers undergo stress tests, coating adhesion checks, and corrosion resistance verification. We follow ASTM International standards for material strength and durability. Third-party inspections are available upon request for quality assurance.

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd|durable fencing solutions&corrosion-resistant coating

NewsJul.30,2025

-

Powder Coated Double Wire Mesh Fence for Germany Market - Anping County Shengxin Metal Products Co., Ltd

NewsJul.30,2025

-

Powder Coated Double Wire Mesh Fence-Anping County Shengxin Metal Products Co., Ltd.|Durability,Aesthetic,Corrosion Resistance

NewsJul.30,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd | Durable & Aesthetic Solution

NewsJul.29,2025

-

Powder Coated Double Wire Mesh Fence - Anping Shengxin|Durable Corrosion Resistant

NewsJul.29,2025

-

Powder Coated Double Wire Mesh Fence-Anping County Shengxin Metal Products Co., Ltd|Durability&Corrosion Resistance

NewsJul.29,2025