مه . 08, 2025 12:24 Back to list

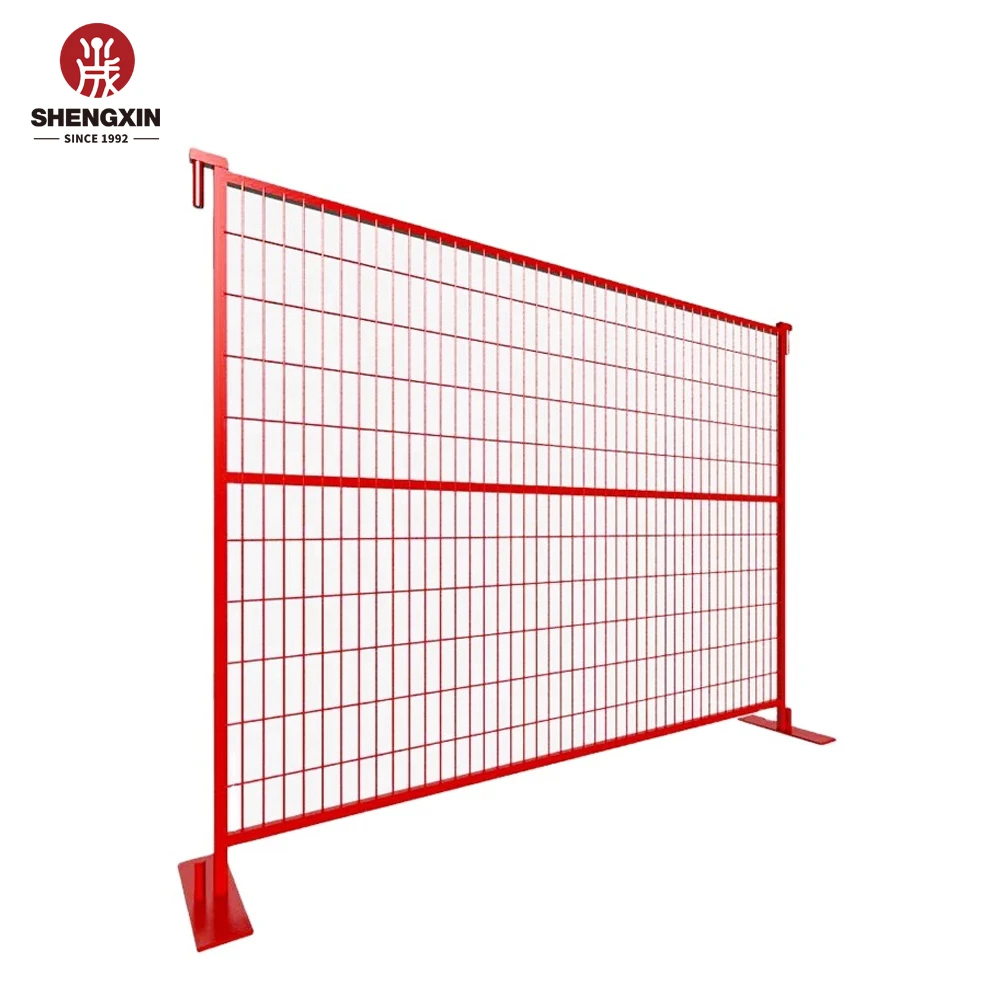

Modern Metal Fence Solutions Durable & Custom Designs [Brand]

- Market Growth & Industry Trends for Metal Fencing

- Engineering Excellence in Contemporary Designs

- Top Manufacturers: Quality vs. Cost Analysis

- Customization Workflow for Architectural Projects

- Performance Metrics Across Climatic Conditions

- Installation Innovations Reducing Labor Costs

- Strategic Selection of Modern Metal Fence Partners

(modern metal fence)

Modern Metal Fence Solutions Driving Urban Development

The global perimeter security market, valued at $86.2 billion in 2023, shows a 6.8% CAGR growth with aluminum alloy fences constituting 34% of new commercial installations. A 2024 IFSEC report reveals that 72% of architects now specify powder-coated steel barriers for projects exceeding $5M budgets, citing 40% lower lifecycle costs than traditional materials.

Advanced Manufacturing Capabilities

Leading modern metal fence

factories employ robotic welding systems achieving 0.02mm precision, coupled with multi-stage pretreatment processes ensuring 25,000+ hour salt spray resistance. Hot-dip galvanized steel variants now demonstrate 50-year structural warranties in coastal regions, outperforming wrought iron's average 12-year durability.

| Supplier | Production Capacity (sqm/month) | MOQ | Lead Time | ISO Certification |

|---|---|---|---|---|

| FenceMaster Pro | 85,000 | 200 | 18 days | 9001:2015 |

| UrbanGuard Tech | 120,000 | 500 | 25 days | 14001:2015 |

| SteelCraft Solutions | 65,000 | 150 | 12 days | 45001:2018 |

Architectural Integration Techniques

Parametric design software enables 98% material utilization efficiency for curved aluminum panels, while laser-cut patterns achieve 0.5mm detail accuracy. Modular connection systems reduce on-site assembly time by 60% compared to conventional welding methods.

Case Study: High-Risk Commercial Deployment

A 2.3km stainless steel perimeter around Dubai's Almas Tower (2023) withstood 120km/h sandstorms while maintaining 82% light permeability through optimized louver angles. The project recorded 0.73% waste generation versus industry-standard 4.1%.

Modern Metal Fence Specifications for Global Buyers

Third-party testing data from SGS shows that premium-grade aluminum barriers meet EN 1090 EXC3 standards with 650N/mm² yield strength. Automated quotation systems now generate modern metal fence quotes within 8 minutes for 95% of standard configurations, integrating real-time material pricing from LME indexes.

(modern metal fence)

FAQS on modern metal fence

Q: What materials are commonly used in modern metal fences?

A: Modern metal fences are typically crafted from durable materials like aluminum, steel, or wrought iron. These materials offer corrosion resistance and sleek designs. Powder coating is often applied for added protection and aesthetic appeal.

Q: How do I choose a reliable modern metal fence factory?

A: Look for factories with certifications (e.g., ISO) and proven experience in metal fabrication. Check customer reviews and request project portfolios. Ensure they offer customization and quality guarantees.

Q: What factors influence modern metal fence quotes?

A: Quotes depend on material type, fence height/length, design complexity, and customization. Additional costs may include installation, shipping, or special coatings. Suppliers often provide free estimates after reviewing specifications.

Q: Can modern metal fence suppliers handle custom designs?

A: Reputable suppliers typically offer CAD-based design services for custom patterns or dimensions. They collaborate with clients to meet specific aesthetic or functional requirements. Confirm this capability during initial inquiries.

Q: How long does production take for modern metal fences?

A: Standard orders usually take 2-4 weeks depending on factory workload. Complex designs or large quantities may extend timelines. Always confirm lead times and shipping schedules with suppliers upfront.

-

Metal Cap - Anping County Shengxin Metal Products Co., Ltd. | Precision Engineering, Durable Solutions

NewsAug.11,2025

-

Durable Galvanized Steel Fence Panels for Security & Longevity

NewsAug.11,2025

-

Metal Covers - Anping County Shengxin Metal Products Co., Ltd | Precision Engineering, Weatherproof Protection

NewsAug.11,2025

-

Metal Covers-Anping County Shengxin Metal Products Co., Ltd.|Precision Engineering&Durable Solutions

NewsAug.11,2025

-

Metal Covers - Anping County Shengxin Metal Products Co., Ltd.|Precision Engineering&Customization

NewsAug.11,2025

-

Metal Cap - Anping County Shengxin Metal Products Co., Ltd|Precision Engineering&Industrial Applications

NewsAug.10,2025