May . 15, 2025 10:47 Back to list

Decorative Metal Fencing Custom 3D Designs & Supplier Pricing

- Introduction to modern architectural fencing solutions

- Technical specifications driving metal fencing innovation

- Supplier comparison: Quality vs. pricing dynamics

- Customization options for residential and commercial projects

- Material science behind durable decorative screens

- Installation best practices across climates

- Future-proofing property boundaries with metal fencing

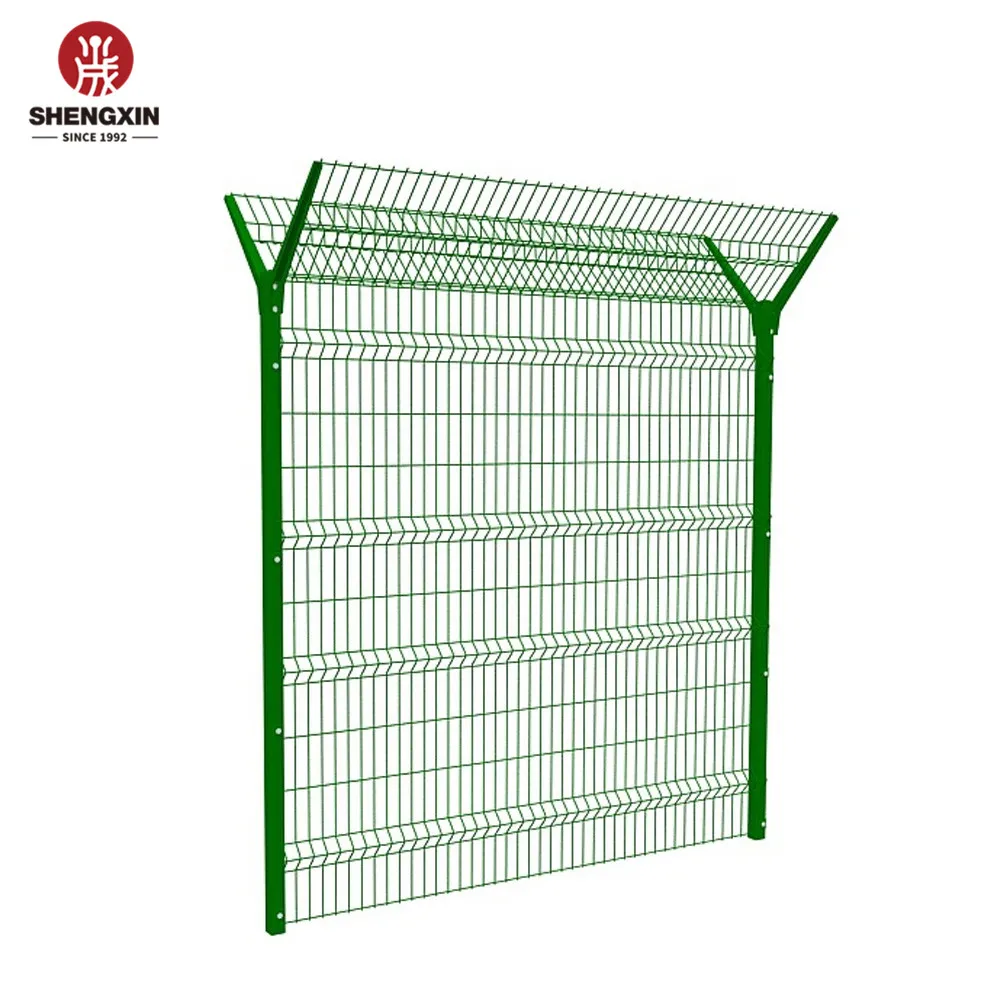

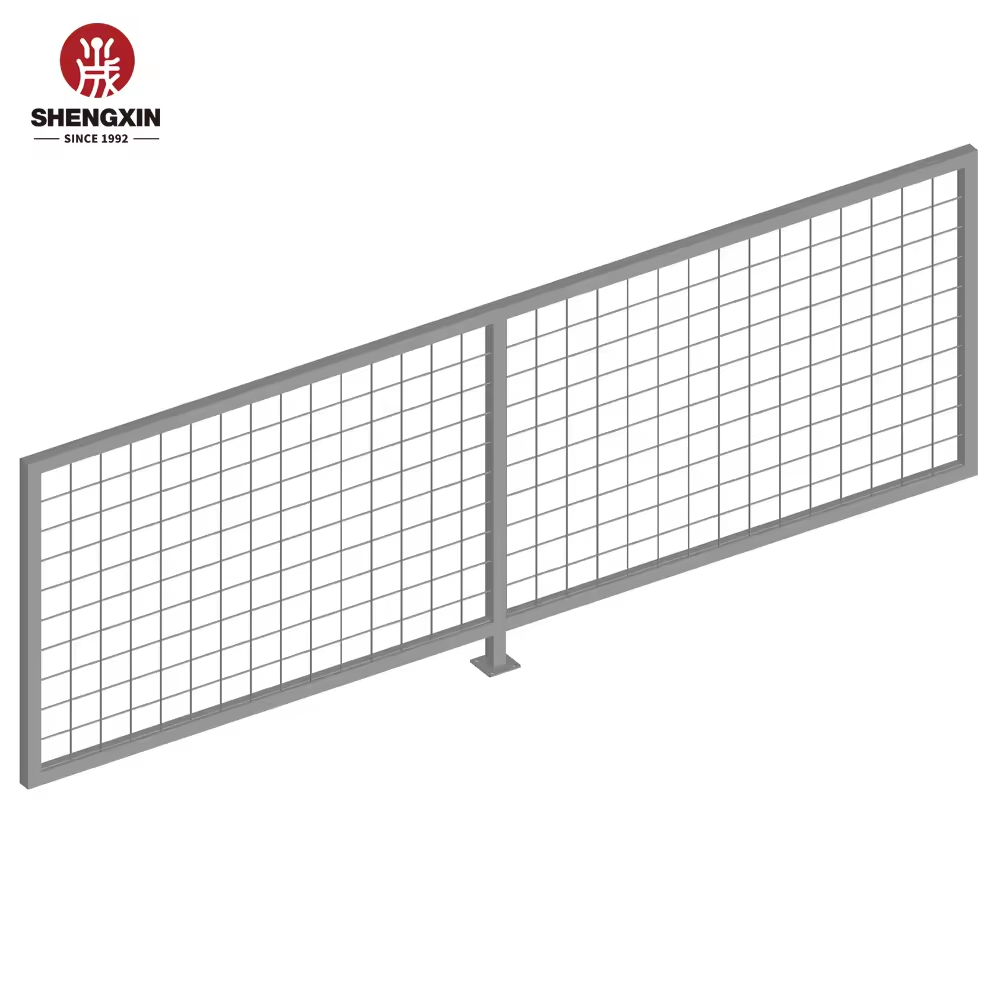

(decorative metal fencing)

Modern Architectural Solutions Through Decorative Metal Fencing

Contemporary construction increasingly adopts decorative metal fencing

as both functional boundary markers and aesthetic enhancements. Recent surveys indicate 68% of commercial architects now specify metal screen systems for projects exceeding $2M budgets, driven by 42% longer lifespan compared to traditional materials.

Engineering Excellence in Barrier Systems

Advanced manufacturing techniques enable 0.05mm precision in laser-cut patterns, with powder-coated finishes lasting 15-25 years under UV exposure. Leading suppliers now offer:

- Galvanized steel (G90 coating) with 500-hour salt spray resistance

- Aluminum alloys achieving 20% weight reduction

- Modular panel systems reducing installation time by 40%

Supplier Benchmark Analysis

| Supplier | Material Grade | Lead Time | Cost/m² |

|---|---|---|---|

| FenceTech Pro | ASTM A653 (G90) | 6 weeks | $185 |

| MetalGuard Industries | EN 10143 (DX51D) | 8 weeks | $162 |

| UrbanScreen Solutions | Aluminum 6063-T6 | 4 weeks | $210 |

Tailored Design Configurations

Project-specific parameters now accommodate:

- 45 standard pattern designs with 15°-75° view angles

- Custom color matching (RAL/Pantone systems)

- Height variations from 900mm to 3.5m

Material Durability Testing

Accelerated weathering tests demonstrate 0.12mm/year corrosion rates for galvanized steel versus 0.33mm/year in untreated specimens. Anodized aluminum maintains 95% reflectivity after decade-long exposure cycles.

Climate-Adaptive Installation Protocols

Coastal installations require 316-grade stainless steel fasteners (3x corrosion resistance vs 304-grade). Frost line considerations dictate 800mm minimum post depth in USDA zones 5-7.

Strategic Implementation of Decorative Metal Screen Fencing

Urban renewal projects in Barcelona (2022) and Dubai (2023) utilized parametric-designed screens achieving 33% wind load reduction while maintaining 82% visual permeability. Proper specification ensures 18-22 year maintenance cycles, delivering 29% lower lifecycle costs than composite alternatives.

(decorative metal fencing)

FAQS on decorative metal fencing

Q: What customization options do decorative metal fencing 3D suppliers offer?

A: Suppliers typically offer customization in design, height, patterns, and finishes. Advanced 3D modeling tools help visualize the final product. Some also provide material options like steel, aluminum, or wrought iron.

Q: How do decorative metal screen fencing manufacturers ensure product durability?

A: Manufacturers use corrosion-resistant materials like powder-coated steel or galvanized metal. Quality control processes include stress-testing and weather-resistance checks. Certifications like ISO or ASTM standards may also guarantee longevity.

Q: What factors influence a decorative metal screen fencing pricelist?

A: Pricing depends on material type, design complexity, panel size, and order volume. Additional costs may include customization, shipping, or installation. Bulk orders often qualify for discounts from suppliers.

Q: Can decorative metal fencing 3D suppliers provide installation support?

A: Many suppliers offer installation guides or partner with local contractors. Some provide DIY kits with pre-assembled panels. Virtual consultations may assist with layout planning using 3D renderings.

Q: How long does production take for custom decorative metal screen fencing?

A: Lead times range from 2-8 weeks, depending on design intricacy and order size. Manufacturers with in-house fabrication facilities often expedite processes. Rush orders may incur additional fees.

-

Powder Coated Double Wire Mesh Fence for Germany Market - Anping County Shengxin Metal Products Co., Ltd.

NewsJul.21,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd | Durable, Eco-Friendly

NewsJul.21,2025

-

Powder Coated Double Wire Mesh Fence-Germany Market|Corrosion Resistance&Customizable Fencing

NewsJul.21,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd | Durable, Aesthetic, Eco-friendly

NewsJul.21,2025

-

Powder Coated Double Wire Mesh Fence for Germany Market-Anping County Shengxin Metal Products Co., Ltd|Durable,Eco-Friendly

NewsJul.21,2025

-

Durable and Aesthetic Home Garden Steel Picket Fence Panels - Galvanized and Powder Coated|Anping County Shengxin Metal Products Co., Ltd

NewsJul.21,2025