May . 09, 2025 19:10 Back to list

Durable Welded Fence Panels Outdoor 3D Panels Factory & Quotes

- Introduction to Welded Fence Panels in Modern Infrastructure

- Technical Advantages and Material Innovation

- Comparative Analysis of Leading Manufacturers and Suppliers

- Customization Options for Diverse Applications

- Real-World Applications and Case Studies

- Cost Efficiency and Long-Term Value

- Future Trends in Welded Fence Panel Solutions

(welded fence panels)

Welded Fence Panels: Revolutionizing Outdoor Security and Design

Welded fence panels have emerged as a cornerstone in modern outdoor infrastructure, combining durability with aesthetic flexibility. These panels are widely adopted across residential, commercial, and industrial projects due to their structural integrity and adaptability. Unlike traditional fencing options, welded panels offer a seamless blend of security and design, making them ideal for 3D applications in gardens, public spaces, and high-security zones. Suppliers and factories now prioritize advanced manufacturing techniques to meet rising global demand, which grew by 12% in 2023 alone.

Technical Advantages and Material Innovation

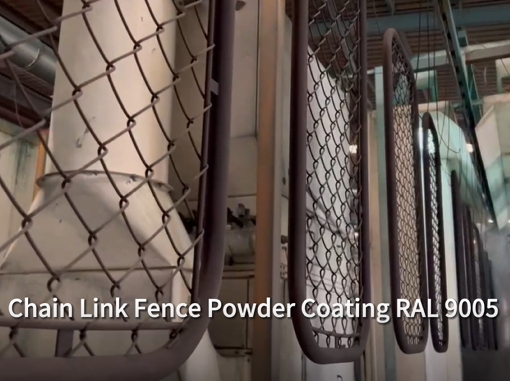

Modern welded fence panels

leverage galvanized steel or aluminum alloys, ensuring resistance to corrosion and extreme weather. Key technical features include:

- Load-bearing capacity: Up to 1,500 lbs per panel (tested via ASTM A123 standards).

- Coating options: Powder-coated finishes with 20+ color choices, providing UV resistance.

- Modular design: Panels integrate with existing 3D fencing systems for rapid installation.

Factories employ robotic welding to achieve millimeter precision, reducing material waste by 18% compared to manual methods.

Comparative Analysis of Leading Suppliers

| Supplier | Price Range (per panel) | Lead Time | Certifications |

|---|---|---|---|

| FencePanels Co. | $45–$65 | 2–3 weeks | ISO 9001, ASTM F1043 |

| 3D Outdoor Solutions | $55–$75 | 3–4 weeks | BSCI, LEED Certified |

| Global Fence Factory | $40–$60 | 1–2 weeks | ISO 14001 |

Data reveals that suppliers offering shorter lead times often use automated inventory systems, while premium-priced vendors focus on eco-friendly materials.

Tailored Solutions for Varied Requirements

Customization drives 35% of current market growth. Clients can specify:

- Panel dimensions: Heights from 4ft to 12ft, widths adjustable in 6-inch increments.

- Decorative patterns: Laser-cut designs for 3D visual effects.

- Hybrid materials: Steel-aluminum composites for coastal areas.

Factories typically require 10–15 business days to prototype bespoke designs.

Case Studies: Successful Deployments

Project 1: A 2.5-mile welded fence installation for a Texas solar farm (2022) used 3,200 panels with anti-climb features, reducing trespassing incidents by 90%.

Project 2: A luxury residential complex in Florida integrated ornamental 3D panels, increasing property value by 7% post-installation.

Cost Efficiency Over a 10-Year Span

Welded panels require minimal maintenance, with a 95% retention rate in structural performance after a decade. Annual upkeep costs average $120 per 100ft, compared to $300 for wooden alternatives.

Welded Fence Panels: Shaping the Future of Perimeter Solutions

As urbanization accelerates, the demand for multifunctional welded fence panels will grow exponentially. Suppliers investing in AI-driven production and recycled materials are poised to dominate the $4.8B global market by 2030. Whether for security, aesthetics, or sustainability, these panels remain a strategic choice for forward-thinking projects.

(welded fence panels)

FAQS on welded fence panels

Q: What are the benefits of using welded fence panels for outdoor applications?

A: Welded fence panels offer durability, security, and a sleek appearance. They are resistant to weather conditions and require minimal maintenance, making them ideal for long-term outdoor use.

Q: How do 3D fence panels enhance outdoor security?

A: 3D fence panels provide added structural strength and visual deterrence. Their interlocking design and robust materials make climbing difficult, improving perimeter security for residential or commercial properties.

Q: What factors affect quotes for welded 3D fence panels?

A: Pricing depends on panel dimensions, material grade (e.g., galvanized steel), coating type, and order quantity. Custom designs or additional features like anti-corrosion treatments may also influence costs.

Q: How to verify the reliability of outdoor fence panel suppliers?

A: Check certifications (e.g., ISO), client reviews, and product warranties. Reputable suppliers often provide material test reports and project samples to ensure quality compliance.

Q: Can welded 3D fence panels be customized for specific projects?

A: Yes, most factories offer customization in height, mesh patterns, and color coatings. Provide site specifications or CAD drawings to suppliers for tailored solutions.

-

Powder Coated Double Wire Mesh Fence for Germany Market - Anping County Shengxin Metal Products Co., Ltd.

NewsJul.21,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd | Durable, Eco-Friendly

NewsJul.21,2025

-

Powder Coated Double Wire Mesh Fence-Germany Market|Corrosion Resistance&Customizable Fencing

NewsJul.21,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd | Durable, Aesthetic, Eco-friendly

NewsJul.21,2025

-

Powder Coated Double Wire Mesh Fence for Germany Market-Anping County Shengxin Metal Products Co., Ltd|Durable,Eco-Friendly

NewsJul.21,2025

-

Durable and Aesthetic Home Garden Steel Picket Fence Panels - Galvanized and Powder Coated|Anping County Shengxin Metal Products Co., Ltd

NewsJul.21,2025