Oct . 20, 2024 19:00 Back to list

welded fence with bends manufacturers

The Importance of Quality in Welded Fence with Bends Manufacturing

Welded fences with bends are an essential component in various industries, providing security, safety, and aesthetic value to properties. Whether used in residential areas, commercial buildings, or industrial sites, these fences offer a robust solution to perimeter protection. The manufacturing process of these fences is crucial, as it determines their durability, functionality, and overall appeal. This article explores the importance of quality in the manufacturing of welded fences with bends and highlights some key manufacturers in the industry.

Understanding Welded Fences with Bends

Welded fences are typically constructed from steel or aluminum, with individual rods or wires welded together to create a strong and stable structure. The bends in these fences serve not only an aesthetic purpose but also enhance the strength and rigidity of the finished product. The design may vary, with different angles and shapes allowing customization based on specific needs. This flexibility in design makes welded fences suitable for a wide range of applications, from residential backyards to commercial properties and construction sites.

The Manufacturing Process

The manufacturing of welded fences involves several key steps cutting, bending, welding, and finishing. Each stage plays a vital role in ensuring the final product meets quality standards.

1. Material Selection The first step in manufacturing welded fences is selecting the high-quality materials. Using galvanized steel or aluminum prevents rust and corrosion, ensuring the longevity of the fence.

2. Cutting and Bending Once the material is chosen, it is cut to size and bent into desired shapes. The bending process must be precise to ensure that the fence maintains its structural integrity and stability.

welded fence with bends manufacturers

3. Welding The welding process is critical, as it holds the entire fence together. Manufacturers should employ skilled welders and advanced welding technologies. A strong weld will contribute to the overall strength of the fence, allowing it to withstand various environmental conditions.

4. Finishing Touches After welding, the fence goes through a series of finishing processes, which may include painting, powder coating, or galvanizing. These finishes not only improve the aesthetic appeal of the fence but also provide additional protection against the elements.

The Role of Quality Control

Quality control is a pivotal aspect of the manufacturing process. Reputable manufacturers implement strict quality assurance protocols to ensure that every welded fence meets stringent standards. Regular inspections during each stage of production help identify any potential defects early on, which can then be rectified before the product reaches the end-user. Additionally, conducting tests for strength and durability guarantees that the final product performs well in real-world conditions.

Key Manufacturers in the Industry

Several manufacturers are prominent in the production of welded fences with bends. They are known for their commitment to quality, advanced manufacturing techniques, and customer service. Companies such as Steel Fences, Inc., Aluminum Fabricators, and Secure Fence Solutions have established reputations for delivering reliable and aesthetically pleasing welded fence products. By employing innovative technologies and adhering to high industry standards, these manufacturers continue to lead the market.

Conclusion

In conclusion, the manufacturing of welded fences with bends is a multifaceted process that requires precision, quality materials, and skilled craftsmanship. The importance of quality cannot be overstated, as it directly affects the durability, safety, and visual appeal of the final product. As security concerns continue to grow in various sectors, the demand for high-quality welded fences will likely remain strong. Investing in reputable manufacturers who prioritize quality will ensure that customers receive products that not only meet their needs but also stand the test of time. Whether for residential, commercial, or industrial use, a well-manufactured welded fence with bends provides peace of mind and lasting protection.

-

Powder Coated Double Wire Mesh Fence-Anping County Shengxin Metal Products Co., Ltd.

NewsAug.02,2025

-

Powder Coated Double Wire Mesh Fence | Anping County Shengxin Metal Products Co., Ltd

NewsAug.02,2025

-

Powder Coated Double Wire Mesh Fence for Germany Market-Anping County Shengxin Metal Products Co., Ltd|Durability, Aesthetics, Compliance

NewsAug.02,2025

-

Powder Coated Double Wire Mesh Fence-Anping County Shengxin Metal Products Co., Ltd.|Durability&Compliance

NewsAug.02,2025

-

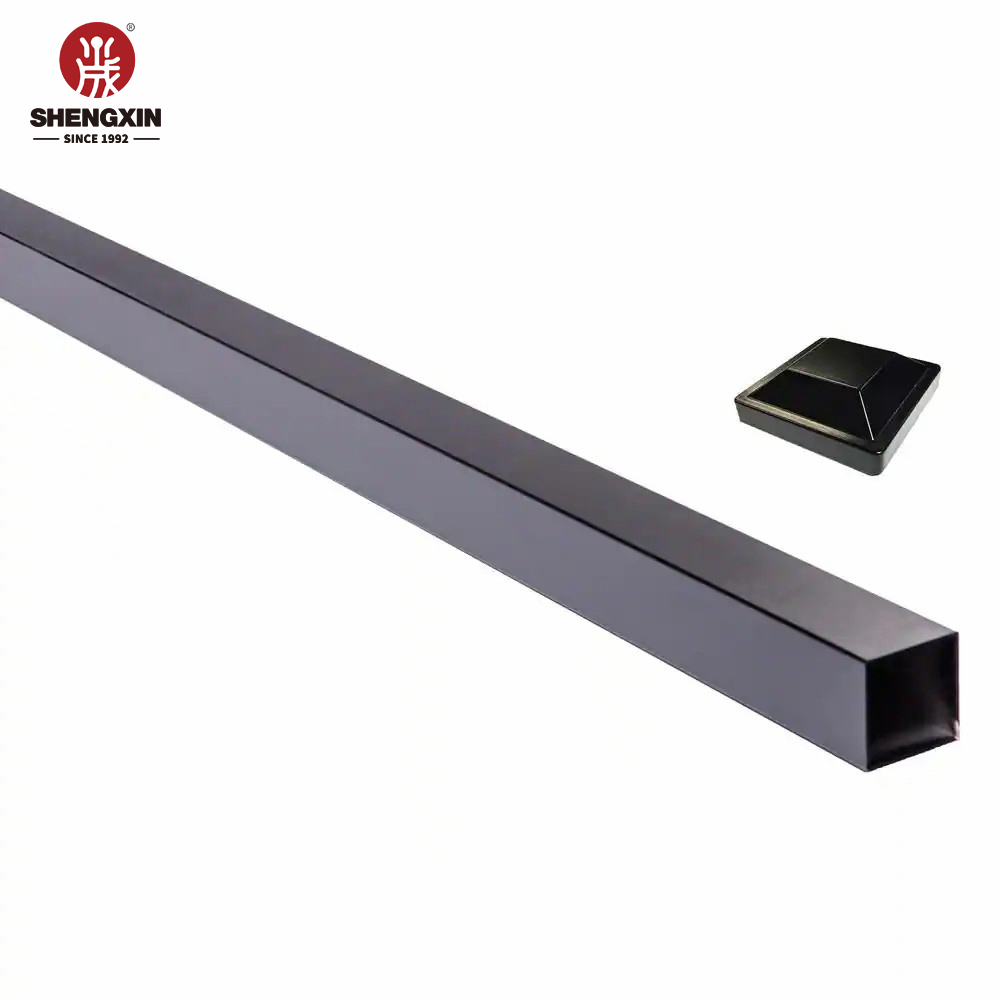

Powder Coated Square Fence Posts | Removable Decorative Metal

NewsAug.02,2025

-

Premium ODM 7' Security Fence - High-Security & Durable

NewsAug.01,2025