des . 26, 2024 17:39 Back to list

galvanized metal fencing factory

The Rise of Galvanized Metal Fencing A Comprehensive Overview of the Industry

In recent years, the demand for durable and adaptable fencing solutions has surged, pushing galvanized metal fencing to the forefront of the market. This type of fencing offers numerous advantages, including longevity, corrosion resistance, and low maintenance, making it an ideal choice for various applications ranging from residential properties to commercial buildings and agricultural facilities. In this article, we will explore the galvanized metal fencing industry, focusing on the manufacturing process, market trends, and its widespread applications.

Understanding Galvanized Metal Fencing

Galvanization is a process where steel or iron is coated with a layer of zinc to protect it from rust and corrosion. This innovative technique not only enhances the metal's lifespan but also reduces the need for frequent maintenance. Galvanized metal fencing is typically constructed from steel wires or panels that have undergone this protective procedure, allowing it to withstand harsh environmental conditions and resist decay over time.

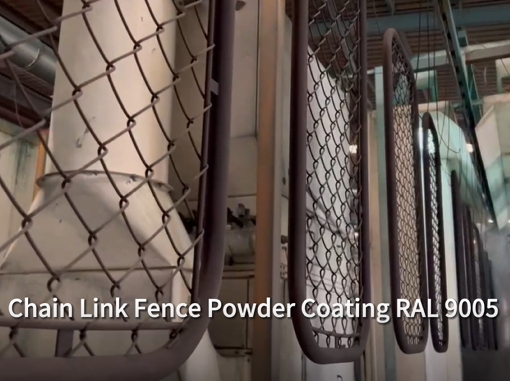

The increase in popularity of this fencing type can be attributed to its aesthetic appeal, strength, and versatility. Buyers can choose from various styles, including chain-link, picket, and panel fencing, which can be tailored to suit the unique needs of their spaces. Additionally, the fencing can be combined with different coatings and treatments to achieve specific colors or textures, making it a popular choice in residential landscaping.

Manufacturing Process

The manufacturing of galvanized metal fencing involves several key stages. Initially, high-quality steel is sourced from reliable suppliers, ensuring the material's strength and durability. The steel is then cut and shaped into the desired fencing design.

Once the base fencing structure is formed, it undergoes the galvanization process. This commonly involves either hot-dip galvanization or electro-galvanization. In hot-dip galvanization, the metal is submerged in molten zinc, allowing it to bond securely to the steel. On the other hand, electro-galvanization uses an electrochemical process to apply a thin layer of zinc. Both methods significantly enhance the corrosion resistance of the fencing.

After galvanization, the fencing is subjected to quality control checks to ensure it meets industry standards. Any defects are addressed, and the fencing is then packaged for shipping. A modern galvanized metal fencing factory employs advanced machinery and technology to streamline production, ultimately improving efficiency and output.

Market Trends and Growth

galvanized metal fencing factory

The market for galvanized metal fencing is expected to continue growing, driven by rising infrastructure development and urbanization. With a growing emphasis on safety and security, businesses and homeowners alike are increasingly turning to galvanized metal fencing as a reliable and effective solution. Moreover, its sustainability factor is a significant draw, as galvanized steel can be recycled at the end of its life span.

In addition, innovations in manufacturing practices and the advent of automated production lines have led to a reduction in production costs. This allows manufacturers to offer competitive pricing, making galvanized metal fencing an attractive option for budget-conscious buyers.

Another trend shaping the market is the growing interest in eco-friendly and sustainable construction materials. Manufacturers are experimenting with environmentally friendly coatings and finishes for galvanized metal fencing, appealing to a market segment that prioritizes green building practices. Such adaptability positions galvanized metal fencing as not only a practical option but a responsible choice as well.

Applications of Galvanized Metal Fencing

Galvanized metal fencing finds application across various sectors. In residential areas, it can serve as perimeter fencing, pet enclosures, or garden boundaries. Its robustness makes it a preferred choice among homeowners looking to enhance security while still maintaining visibility.

In commercial settings, businesses utilize galvanized fencing for security purposes, particularly around warehouses, storage areas, and construction sites. The fencing provides a secure barrier while allowing for safety and accessibility.

Moreover, agricultural applications are significant, with farmers using galvanized metal fencing for livestock enclosures, crop protection, and property boundaries. The resilience of galvanized metal to rust guarantees that it remains functional and visually appealing over long periods, translating to significant cost savings over time.

Conclusion

In summary, galvanized metal fencing is a versatile and durable option that meets the fencing needs of various sectors. With continued advancements in manufacturing processes and a growing focus on sustainability, galvanized metal fencing is poised to remain a popular choice. As the industry evolves, consumers can expect innovative practices that enhance both quality and aesthetics, confirming galvanized metal fencing’s place in the modern landscape.

-

Powder Coated Double Wire Mesh Fence-Anping County Shengxin Metal Products Co., Ltd

NewsAug.03,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd

NewsAug.03,2025

-

Power Coated 358 Anti Climb Mesh Fence for Airports

NewsAug.03,2025

-

Powder Coated Double Wire Mesh Fence-Anping County Shengxin Metal Products Co., Ltd.

NewsAug.02,2025

-

Powder Coated Double Wire Mesh Fence | Anping County Shengxin Metal Products Co., Ltd

NewsAug.02,2025

-

Powder Coated Double Wire Mesh Fence for Germany Market-Anping County Shengxin Metal Products Co., Ltd|Durability, Aesthetics, Compliance

NewsAug.02,2025