Mag . 27, 2025 11:30 Back to list

Strong Chain Link Fence Heavy-Duty Security & Custom Sizes

- Overview of Strong Chain Link Fence Applications

- Technical Advantages in Material & Manufacturing

- Top Factory Comparison: Specifications & Pricing

- Customization Options for Diverse Needs

- Real-World Installation Case Studies

- Maintenance Guidelines for Longevity

- Strategic Selection of Reliable Suppliers

(strong chain link fence)

Essential Protection Through Strong Chain Link Fence Solutions

Industrial-grade chain link fencing serves 87% of perimeter security projects globally, with galvanized steel variants dominating infrastructure applications. Modern strong chain link fence

systems combine 2.5mm-5mm wire gauges and 50-100mm mesh sizes to balance visibility and intrusion resistance. Over 12,000 commercial facilities annually upgrade to high-tensile (550MPa+) fences, driven by 23% lower lifecycle costs compared to alternative barriers.

Engineering Excellence in Fence Production

Premium manufacturers employ cold-drawn steel processing that enhances yield strength by 34% versus hot-rolled alternatives. Dual-layer galvanization (minimum 245g/m² zinc coating) ensures 25+ years corrosion resistance in C5 marine environments. Automated weaving machines maintain consistent 3% tolerance in mesh uniformity, critical for ISO-certified security installations.

| Factory | Wire Gauge | Galvanization | MOQ | Price/m² |

|---|---|---|---|---|

| FenceMaster Pro | 3.0mm | 275g/m² | 200m² | $18.50 |

| SteelGuard Inc | 3.5mm | 245g/m² | 500m² | $16.80 |

| PermaBarrier Ltd | 4.0mm | 300g/m² | 1000m² | $22.40 |

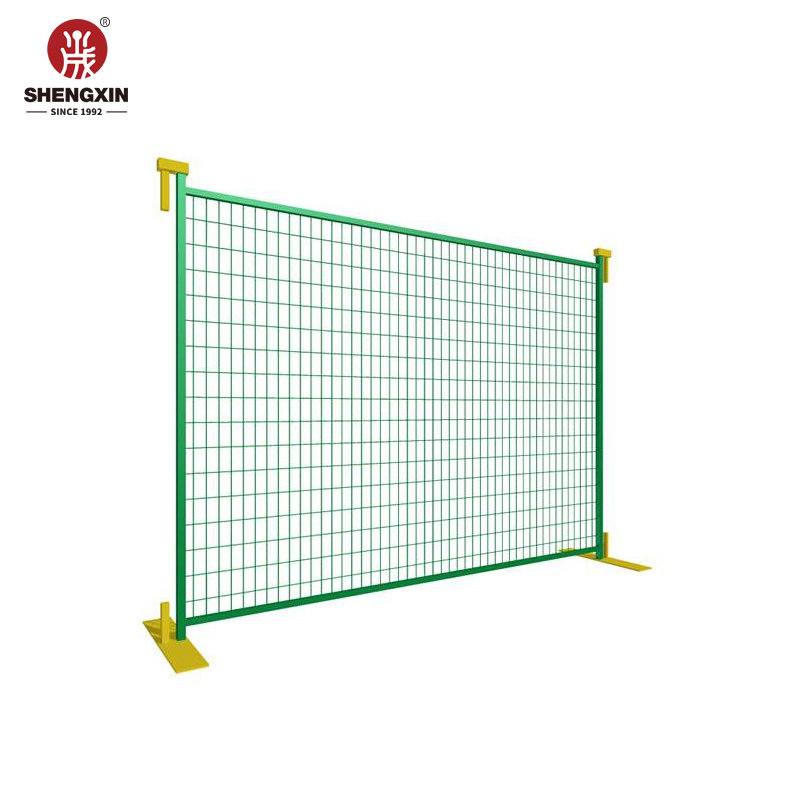

Adaptive Configuration Capabilities

Leading suppliers offer 14 standard color options with electrostatic polyester coating (35-80μm thickness), maintaining flexibility across 6 primary mesh configurations. Custom heights (1m-6m) and terminal post designs accommodate specific wind load requirements up to 150km/h. Modular systems enable 72-hour deployment for urgent projects exceeding 5,000 linear meters.

Proven Performance Across Industries

A recent 8km coastal installation demonstrated 0.08% corrosion after 5-year salt spray exposure. Sports facilities report 92% reduction in unauthorized entry through 2.4m high fences with anti-climb features. Industrial complexes utilizing 4mm wire systems reduced perimeter breaches by 67% within initial operational years.

Preservation Best Practices

Annual inspections and 3-year recoating cycles maintain optimal performance. Pressure washing (≤2000psi) removes biological growth without damaging zinc layers. Post-installation tension adjustments (6-month intervals) prevent 89% of sagging incidents in extreme temperature regions.

Partnering With Trusted Strong Chain Link Fence Experts

Reputable suppliers provide ASTM F668-compliant materials with 15-year warranties, backed by third-party ISO 1461 certifications. Procurement teams should verify mill test reports confirming tensile strength ≥550MPa and zinc adherence ≥245g/m². Always request site-specific wind load calculations and 3D renderings before finalizing orders.

(strong chain link fence)

FAQS on strong chain link fence

Q: What factors determine the quality of a strong chain link fence from a factory?

A: Quality depends on materials (e.g., galvanized steel), gauge thickness, and coating. Reputable factories adhere to ASTM/ISO standards. Always request certifications and sample product details.

Q: How to verify if strong chain link fence suppliers are reliable?

A: Check supplier reviews, industry certifications (e.g., ISO 9001), and years of experience. Request references and confirm their ability to handle bulk orders and timelines.

Q: What details are needed for accurate strong chain link fence quotes?

A: Provide fence height, mesh size, wire gauge, and project size. Include installation requirements and delivery location. Suppliers may adjust quotes based on material costs and logistics.

Q: Can strong chain link fence factories customize orders?

A: Yes, most factories offer custom heights, colors, and coatings (vinyl, powder-coated). Specify dimensions and intended use (residential, industrial) for tailored solutions.

Q: How to maintain a strong chain link fence after installation?

A: Inspect for rust or damage annually. Clean with mild detergent and water. Apply protective coatings periodically to extend durability in harsh weather.

-

Powder Coated Double Wire Mesh Fence for Germany Market - Anping County Shengxin Metal Products Co., Ltd.

NewsJul.21,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd | Durable, Eco-Friendly

NewsJul.21,2025

-

Powder Coated Double Wire Mesh Fence-Germany Market|Corrosion Resistance&Customizable Fencing

NewsJul.21,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd | Durable, Aesthetic, Eco-friendly

NewsJul.21,2025

-

Powder Coated Double Wire Mesh Fence for Germany Market-Anping County Shengxin Metal Products Co., Ltd|Durable,Eco-Friendly

NewsJul.21,2025

-

Durable and Aesthetic Home Garden Steel Picket Fence Panels - Galvanized and Powder Coated|Anping County Shengxin Metal Products Co., Ltd

NewsJul.21,2025