11月 . 04, 2024 13:52 Back to list

Innovative 3D Solutions for Modern Manufacturing and Design Challenges

FENC 3D Company Revolutionizing the Future of Manufacturing

In today's fast-paced technological landscape, innovation is the cornerstone of success. Among the trailblazers in the manufacturing sector, FENC 3D Company stands out as a pioneer in the realm of 3D printing and additive manufacturing. With a commitment to quality and sustainability, FENC 3D is transforming traditional manufacturing methods and redefining how products are created, designed, and delivered.

Introduction to FENC 3D

Founded on the principles of innovation, efficiency, and sustainability, FENC 3D Company has emerged as a leader in the 3D printing industry. The company specializes in producing high-quality, precision-engineered components for various sectors, including aerospace, automotive, healthcare, and consumer goods. By utilizing state-of-the-art 3D printing technologies, FENC 3D enables businesses to reduce lead times, minimize waste, and cut costs, ultimately leading to more efficient production processes.

The Technology Behind FENC 3D

At the heart of FENC 3D's offerings is an array of advanced technologies that push the boundaries of traditional manufacturing. The company employs techniques such as Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), and Stereolithography (SLA), each chosen for its specific advantages depending on the application.

1. Fused Deposition Modeling (FDM) This widely used technique involves extruding melted thermoplastic filament layer by layer to create solid objects. FDM is particularly valued for its versatility and cost-effectiveness, making it ideal for prototyping and low-volume production.

2. Selective Laser Sintering (SLS) SLS uses a high-powered laser to fuse small particles of plastic, metal, or ceramic powders into solid structures. This technology allows for the creation of complex geometries that are often impossible to achieve with traditional manufacturing methods. SLS is especially beneficial for producing functional prototypes and end-use parts.

3. Stereolithography (SLA) Utilizing UV light to cure photopolymer resin, SLA enables the production of highly detailed and smooth surfaces. This technology is favored for applications requiring high precision, such as in the medical and dental fields.

fenc 3d company

Commitment to Sustainability

FENC 3D Company is not only focused on technological advancement but also on promoting sustainable practices within the industry. With the manufacturing sector being a significant contributor to environmental challenges, FENC 3D is dedicated to developing eco-friendly materials and reducing the carbon footprint of its operations.

The company actively researches and implements biodegradable and recyclable materials in its 3D printing processes. By doing so, FENC 3D not only meets regulatory requirements but also appeals to environmentally conscious consumers and businesses looking to minimize their impact on the planet.

Enabling Customization and Innovation

One of the standout features of FENC 3D's technology is its capability for mass customization. Traditional manufacturing often requires significant time and resources to create bespoke products, but with 3D printing, customization is streamlined and made accessible. This flexibility allows clients to adapt designs based on specific needs without incurring prohibitive costs or extensive lead times.

For industries such as healthcare, where personalized solutions can dramatically improve patient outcomes, FENC 3D provides tailored products such as custom prosthetics and implants designed to fit the unique anatomy of each patient. This innovative approach not only enhances the quality of care but also showcases the potential of 3D printing to transform industries.

Conclusion

FENC 3D Company is at the forefront of a manufacturing revolution, utilizing cutting-edge technology to enhance efficiency, sustainability, and customization in production. As industries continue to evolve and the demand for innovative solutions grows, FENC 3D is poised to lead the charge, shaping the future of manufacturing with its commitment to excellence and sustainability. Through its pioneering efforts, FENC 3D is not just manufacturing products; it is crafting the future.

-

868 and 656 Wire Fence Factory & Suppliers - Durable Security Fencing Solutions

NewsJun.24,2025

-

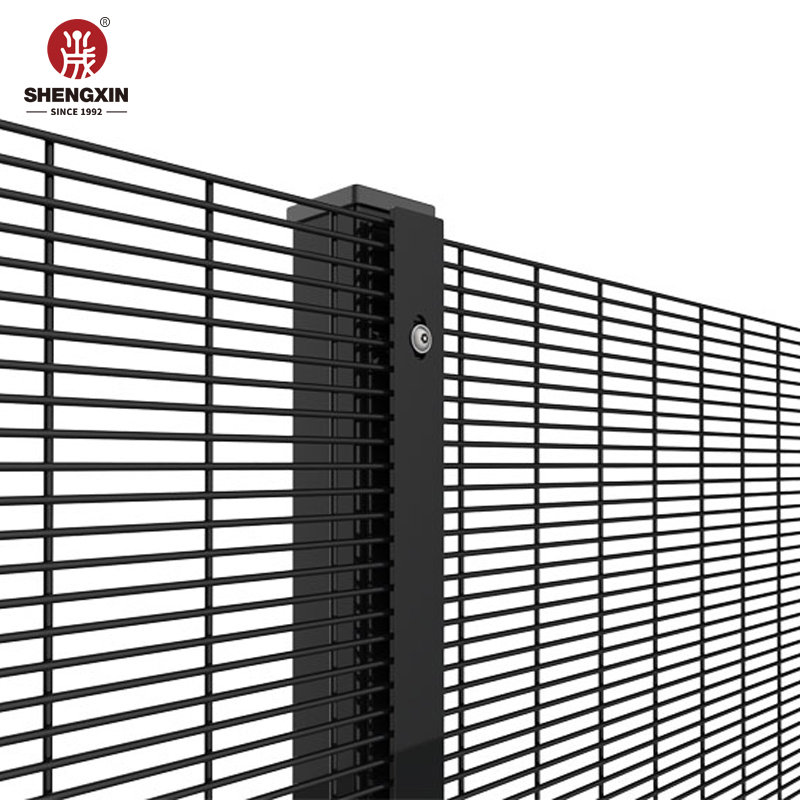

FENC 3D Mesh Fence – Durable, Secure & Easy Installation Custom Quotes & Factory Direct Supply

NewsJun.10,2025

-

Decorative Metal Fencing 3D Supplier – Custom Metal Screen Fencing Manufacturer & Pricelist

NewsJun.10,2025

-

High-Quality Metal Fence Panel - Durable Metal Brown Panel Fence Product & Exporter

NewsJun.10,2025

-

Lawn Chain Link Fencing - Durable & Affordable Solutions Secure Lawn Fences

NewsJun.10,2025

-

Heavy-Duty Metal Fence Posts for Deer Control Factory Direct Supplier

NewsJun.10,2025