Spa . 30, 2024 13:43 Back to list

metal wire fence panels factories

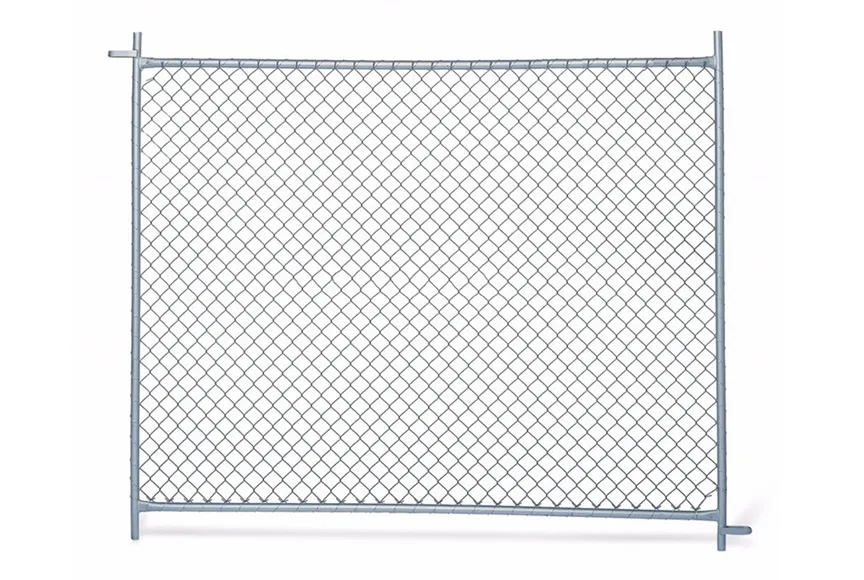

Exploring the World of Metal Wire Fence Panels An Insight into Factories and Production

In today's world, security and aesthetics go hand in hand, making metal wire fence panels an increasingly popular choice for residential, commercial, and industrial applications

. With an emphasis on durability, functionality, and style, many factories are dedicated to producing high-quality metal wire fence panels to meet the diverse needs of consumers.Metal wire fence panels are manufactured using various metals, including galvanized steel, aluminum, and wrought iron. Each material has its own set of advantages, allowing consumers to choose based on their specific requirements. Galvanized steel, for instance, is renowned for its corrosion resistance and strength, making it suitable for harsh weather conditions. Aluminum offers a lightweight alternative that is also resistant to rust, while wrought iron is often favored for its classic appearance and robustness.

The production process of metal wire fence panels begins with sourcing high-quality raw materials. Factories generally establish relationships with reputable suppliers to ensure that the materials used are both durable and compliant with industry standards. After the raw materials are procured, the manufacturing process includes several key steps cutting, welding, and coating.

Cutting involves processing the raw wire into specified lengths, readying them for assembly. Welding is a crucial stage where different components are joined together to form a panel. Automated welding machines are commonly used in factories to enhance precision and improve production efficiency. This step is vital because the strength and resilience of the fence panels rely heavily on the quality of the welds.

metal wire fence panels factories

Once the panels are assembled, they undergo a coating process to improve their resistance to environmental factors. Popular coating methods include powder coating and galvanization, which protect the metal from rust and enhance the panel's aesthetic appeal. Factories often offer a range of colors and finishes, allowing customers to select panels that complement their property’s design.

Quality control is another integral part of the manufacturing process. Factories employ strict quality assurance protocols to ensure that every panel meets safety and performance standards. This may include load testing and inspections for defects, ensuring that the final product is reliable and long-lasting.

Furthermore, with the rise of sustainability concerns, many factories are now adopting eco-friendly practices. This includes utilizing recycled materials where possible and minimizing waste during production. By implementing green technologies, these manufacturers not only reduce their environmental footprint but also appeal to an increasingly conscientious consumer base.

In conclusion, metal wire fence panels are a practical solution for security and aesthetics in various settings, with many factories dedicated to their production. By utilizing advanced manufacturing techniques and adhering to quality and sustainability standards, these factories play a crucial role in providing robust fencing solutions. As the demand for such products continues to grow, innovation and quality assurance will remain paramount in the industry, ensuring customers receive the best possible materials for their fencing needs.

-

Powder Coated Double Wire Mesh Fence- Anping County Shengxin Metal Products Co., Ltd|Durability, Customization, Eco-Friendly

NewsAug.05,2025

-

Powder Coated Double Wire Mesh Fence-Anping County Shengxin Metal Products|Durability&Customization

NewsAug.05,2025

-

Powder Coated Double Wire Mesh Fence Germany Market - Anping

NewsAug.05,2025

-

Durable Chain Link Temporary Fence | Quick Setup & Security

NewsAug.05,2025

-

Coated Galvanized Steel Wire Mesh Fencing Panels | Durability & Protection

NewsAug.04,2025

-

Powder Coated Double Wire Mesh Fence-Anping County Shengxin Metal Products Co., Ltd

NewsAug.03,2025