Sep . 01, 2025 01:40 Back to list

3D Welded Curved Panel Fence - Strong & Stylish Security

Driving Modern Perimeter Security: The 3d welded curved panel fence

In the dynamic landscape of industrial, commercial, and public infrastructure development, the demand for robust, aesthetically pleasing, and cost-effective perimeter security solutions has never been more critical. Traditional fencing often falls short in balancing security with visual integration, leading to a surge in innovative designs. Among these, the 3d welded curved panel fence has emerged as a preferred solution, offering a harmonious blend of structural integrity, visual appeal, and long-term durability. This advanced fencing system is meticulously engineered to address the evolving security challenges faced by B2B decision-makers and project engineers, providing superior protection without compromising the architectural integrity of the secured premises.

Industry Trends in Advanced Perimeter Solutions

Current industry trends highlight a significant shift towards fencing solutions that offer enhanced security features, simplified installation, and extended service life, alongside sustainable manufacturing practices. Clients are increasingly looking for systems that not only deter intrusion but also integrate seamlessly with modern architectural designs, minimizing visual obstruction while maximizing protection. The rise of smart cities and intelligent infrastructure projects further emphasizes the need for fencing systems compatible with integrated security technologies, such as CCTV, access control, and sensor systems. Furthermore, material science advancements continue to push the boundaries of corrosion resistance and material strength, ensuring that investments in perimeter security deliver sustained value over decades. The 3d wire mesh fence panel, with its inherent structural advantages and diverse finishing options, is perfectly positioned to meet these multifaceted demands, offering a future-proof solution for a wide array of applications.

The Precision Manufacturing Process of the 3D Welded Curved Panel Fence

The manufacturing of a high-quality 3d welded curved panel fence is a sophisticated process that combines advanced material science with precision engineering. Each step is rigorously controlled to ensure the final product meets stringent quality standards and offers unparalleled performance in diverse environmental conditions. This detailed process flow guarantees the structural integrity, corrosion resistance, and aesthetic consistency demanded by B2B clientele across various sectors.

Key Materials and Their Properties

- High-Quality Low-Carbon Steel Wire: The foundation of our panels, selected for its excellent ductility and weldability. Typical grades conform to ASTM A641 or EN 10223-4, ensuring optimal tensile strength (typically 500-700 MPa) and yield strength.

- Zinc Coating (Galvanization): Applied via hot-dip galvanizing (conforming to ASTM A123/A123M or ISO 1461) or electro-galvanizing, providing a sacrificial layer that protects the steel from corrosion. Hot-dip galvanizing offers superior coating thickness (typically 45-80 microns) and longer service life, often exceeding 20 years in standard atmospheric conditions.

- Polyester Powder Coating: An additional protective and aesthetic layer applied over the galvanized surface. This coating, adhering to standards like Qualicoat or AAMA 2603/2604, offers enhanced UV resistance, abrasion resistance, and a wide range of RAL colors for architectural integration. The thickness typically ranges from 80-120 microns.

Manufacturing Process Steps

- Pre-treatment: Panels undergo a multi-stage cleaning process, including degreasing and phosphating, to ensure optimal adhesion of the coatings.

- Galvanization: Panels are either hot-dip galvanized or electro-galvanized, forming a robust corrosion-resistant zinc layer.

- Powder Coating: After galvanization, an electrostatic powder coating is applied and then cured in an oven at high temperatures (e.g., 200°C). This creates a durable, weather-resistant, and aesthetically pleasing finish for the 3d curved welded wire mesh fence panel.

The meticulous adherence to these processes ensures a service life often exceeding 15-20 years, even in challenging environments. Target industries include petrochemical, metallurgy, water supply & drainage, renewable energy, and critical infrastructure projects, where corrosion resistance and long-term reliability are paramount.

Technical Specifications: 3D Curvy Welded Wire Mesh Fence Panel

Understanding the precise technical parameters of a 3d welded curved panel fence is crucial for project specification and ensuring optimal performance. Below is a detailed table outlining typical specifications for our standard 3D Curvy Welded Wire Mesh Fence Panels, which can be adapted to meet specific project requirements.

| Parameter | Specification / Range | Notes / Standards |

|---|---|---|

| Wire Diameter (Horizontal/Vertical) | 4.0mm to 6.0mm (e.g., 5.0mm standard) | Higher diameter for increased rigidity and security. Tolerances per EN 10218-2. |

| Mesh Opening (Aperture) | 50x200mm, 50x150mm, 75x200mm | Smaller apertures enhance anti-climb features and security. |

| Panel Height | 1.0m to 2.4m (e.g., 1.73m, 2.03m standard) | Custom heights available. Measured from bottom to top edge of panel. |

| Panel Width | 2.0m to 3.0m (e.g., 2.5m standard) | Standard width for efficient installation. |

| Number of Curves (V-bends) | 2 to 5, depending on panel height | Curves provide rigidity and act as anti-climb deterrents. |

| Post Type | Square Hollow Section (SHS) | Commonly 60x60mm, 80x80mm, or 100x100mm. |

| Post Thickness | 1.5mm to 3.0mm | Thicker posts offer greater structural stability. |

| Surface Treatment | Hot-dip Galvanized + Polyester Powder Coated | Optimal for corrosion resistance and aesthetic appeal. Meets ISO 1461, Qualicoat. |

| Coating Thickness (Zinc) | ≥ 45 microns (Hot-dip) | Ensures long-term rust protection. |

| Coating Thickness (Powder) | 80-120 microns | Enhanced UV and abrasion resistance. |

| Color Options | RAL 6005 (Green), RAL 7016 (Anthracite Grey), RAL 9005 (Black) standard; others available. | Custom colors upon request, subject to minimum order quantity. |

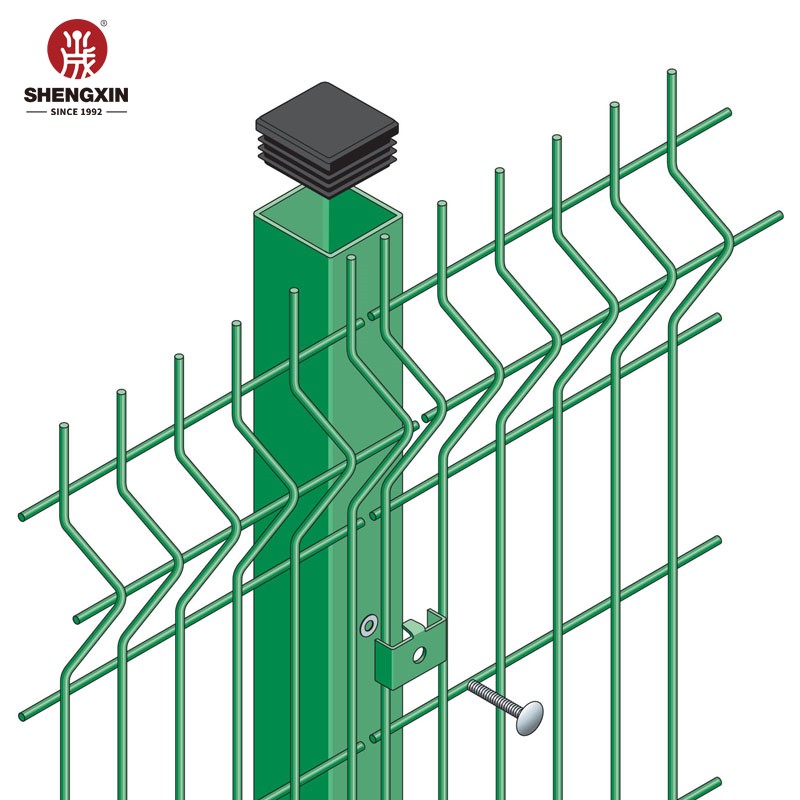

| Installation Accessories | Steel or plastic clamps, bolts & nuts, rain caps for posts. | Matched to post dimensions and panel requirements. |

These specifications highlight the versatility and robust design of the 3d curved welded wire mesh fence panel, making it adaptable for various security levels and aesthetic preferences across a broad spectrum of projects.

Application Scenarios and Technical Advantages

The inherent strength, versatility, and aesthetic appeal of the 3d welded curved panel fence make it an ideal choice for a diverse range of application scenarios where both security and visual integration are paramount. Its design provides significant technical advantages over conventional fencing options.

Typical Application Scenarios

- Industrial and Commercial Facilities: Securing factories, warehouses, logistics centers, data centers, and corporate campuses. The robust construction deters unauthorized access, protecting valuable assets and sensitive information.

- Public Infrastructure: Enclosing airports, railway lines, harbors, power stations, telecommunication sites, and water treatment plants. Its anti-climb design and high visibility contribute to public safety and critical asset protection.

- Residential and Educational Institutions: Defining perimeters for gated communities, schools, universities, and residential estates. It provides a secure environment while maintaining an open, unthreatening aesthetic.

- Parks and Recreational Areas: Fencing sports fields, public parks, and playgrounds. The transparent design minimizes visual impact while ensuring safety and controlled access.

- Military and Correctional Facilities: Used as a primary or secondary perimeter barrier, often integrated with advanced security systems, due to its formidable resistance to cutting and climbing attempts.

- Highways and Railways: Used along transportation corridors to prevent unauthorized crossings and maintain safety.

Technical Advantages

- Superior Rigidity and Anti-Climb Properties: The unique 3D V-bends engineered into the panels significantly increase their horizontal rigidity, making them highly resistant to bending, cutting, and tampering. These curves also eliminate footholds, acting as a strong deterrent against climbing.

- Exceptional Corrosion Resistance: The multi-layered protective coating, typically hot-dip galvanization followed by an architectural-grade polyester powder coating, provides unparalleled resistance against rust, UV radiation, and harsh weather conditions. This ensures a prolonged service life with minimal degradation.

- High Visibility and Aesthetic Appeal: The open mesh design offers excellent visibility, crucial for surveillance systems, while its modern, clean lines enhance the aesthetic value of the secured property. The wide range of RAL colors allows for perfect integration with architectural themes.

- Ease and Speed of Installation: Designed for modular assembly, these panels can be rapidly installed, reducing labor costs and project timelines. The simple yet secure post-and-clamp system facilitates quick erection on various terrains.

- Low Maintenance Requirements: Thanks to its durable construction and advanced surface treatments, the 3d welded curved panel fence requires minimal maintenance, translating into lower operational costs over its lifespan.

- Environmental Resilience: The materials and coatings are designed to withstand extreme temperatures, high humidity, and corrosive industrial atmospheres, ensuring consistent performance in diverse global environments.

These advantages underscore why the 3d curved welded wire mesh fence panel is a preferred choice for professionals seeking a high-performance, long-lasting, and visually appealing security solution.

Vendor Comparison and Customized Solutions

Selecting the right vendor for your 3d welded curved panel fence requirements is as critical as the product itself. A reliable supplier offers not just quality products but also expertise, flexibility, and robust after-sales support. Our commitment to excellence is reflected in our certifications and long-standing industry presence.

Key Differentiators in Vendor Selection

| Feature | Our Offering | Typical Market Standard |

|---|---|---|

| Quality Certifications | ISO 9001:2015, CE Certified, ASTM/ANSI compliant materials. Batch-specific material test reports. | May vary, often limited to basic material certificates, less rigorous quality management. |

| Experience & Specialization | Decades of specialized experience in high-security fencing; extensive portfolio of large-scale B2B projects globally. | General fabrication experience, less specific focus on complex perimeter solutions. |

| Customization Capability | Full engineering support for bespoke dimensions, mesh configurations, post types, colors, and integrated security features. | Limited standard sizes and colors, minimal engineering support for unique project needs. |

| Corrosion Protection | Hot-dip galvanized (≥45µm) + marine-grade polyester powder coat (80-120µm). 10-year coating warranty. | Electro-galvanized or lighter hot-dip coating, standard powder coat, shorter/no coating warranty. |

| Lead Time & Logistics | Optimized production lines for efficient delivery; global logistics network; clear fulfillment schedules. | Variable production capacity, potential delays, limited shipping options. |

| Technical Support | Dedicated project managers, CAD drawings, installation guides, on-site consultation for complex projects. | Basic product information, limited design or installation assistance. |

Our extensive experience and adherence to international standards mean that our 3d wire mesh fence panel solutions consistently meet or exceed client expectations, providing long-term reliability and peace of mind.

Comprehensive Customized Solutions

Recognizing that no two projects are identical, we offer extensive customization options for the 3d curved welded wire mesh fence panel to perfectly align with specific site requirements, security protocols, and aesthetic preferences. Our engineering team collaborates closely with clients from conceptualization to deployment.

- Panel Dimensions: Tailored heights and widths to accommodate uneven terrain, specific security clearances, or architectural integration.

- Wire Gauge and Mesh Aperture: Options for varying wire diameters (e.g., 4mm, 5mm, 6mm) and mesh sizes (e.g., 50x100mm, 75x200mm) to achieve desired security levels, from aesthetic demarcation to high-security anti-climb barriers.

- Coating Specifications: Beyond standard hot-dip galvanization and powder coating, specialized anti-graffiti, anti-corrosion, or marine-grade coatings can be applied for extreme environments.

- Color Matching: Custom RAL color matching to align with corporate branding, environmental aesthetics, or local planning regulations.

- Post Systems: Various post types (square, rectangular, circular), dimensions, and anchoring methods (concrete-in, bolted flange) to suit ground conditions and security needs. Integration with specialized post caps for anti-climb features or wiring conduits.

- Integrated Security Features: Seamless integration with razor wire, barbed wire, anti-climb spikes, CCTV camera mounts, lighting systems, and access control points (gates, turnstiles).

Our consultative approach ensures that every aspect of your 3d welded curved panel fence solution is optimized for performance, longevity, and value.

Application Case Studies and Trust Elements

Real-World Application Case Studies

Our 3d welded curved panel fence solutions have been successfully deployed in numerous demanding environments, consistently delivering superior security and aesthetic results. Here are a few examples demonstrating our capabilities:

- Case Study 1: High-Security Data Center Perimeter ( EMEA Region)

A leading global technology company required a robust and visually discreet perimeter solution for their new data center. We supplied custom-height 3d welded curved panel fence panels (2.4m high, 5.0mm wire, 50x150mm mesh) with additional anti-climb features and a dark grey powder coating (RAL 7016) to blend with the architectural design. The fence was integrated with passive infrared sensors and CCTV systems. The project was completed on schedule, providing a high-security barrier with minimal visual impact, as evidenced by positive client feedback regarding system rigidity and aesthetic integration.

- Case Study 2: Municipal Sports Complex (North America)

A municipal authority sought a durable, low-maintenance fencing system for a multi-sport complex, requiring both pedestrian safety and property delineation. We provided 1.8m high 3d wire mesh fence panel in a vibrant green (RAL 6005) with 60x60mm square posts. The ease of installation allowed the project to be completed within a tight municipal budget and timeline. The robust galvanized and powder-coated finish ensures longevity against harsh weather and extensive public use, reducing long-term maintenance costs for the city.

- Case Study 3: Coastal Industrial Park (APAC Region)

Facing severe saltwater corrosion, an industrial park located near a coastal area needed a perimeter fence capable of withstanding extreme environmental conditions. We delivered a bespoke 3d curved welded wire mesh fence panel solution featuring extra-thick hot-dip galvanization (min. 80µm) followed by a specialized marine-grade polyester powder coating. This enhanced treatment significantly extended the expected service life, outperforming previous fencing materials that degraded rapidly in the saline atmosphere. The client reported excellent performance and structural integrity after several years of exposure.

Trustworthiness: FAQ, Lead Time, Warranty, and Support

Building trust with our B2B partners is paramount. We provide clear commitments regarding product quality, delivery, and post-sales support.

Frequently Asked Questions (FAQ)

- Q: What is the typical lifespan of a 3d welded curved panel fence?

A: With proper installation and our advanced galvanization plus powder coating, a service life of 15-20 years is standard, often exceeding 25 years in less aggressive environments. - Q: Can the fence be installed on uneven terrain?

A: Yes, our panels are designed to accommodate varying ground levels through stepped installation or custom-cut panels. Our technical team can provide detailed guidance. - Q: Are the posts included with the panels?

A: Posts and all necessary installation accessories (clamps, bolts, rain caps) are typically supplied as a complete system, ensuring compatibility and ease of assembly. - Q: What maintenance is required for the 3d welded curved panel fence?

A: Minimal maintenance is required. Periodic cleaning with mild soap and water can maintain its aesthetic appeal. Inspect for any physical damage after severe weather or incidents.

Lead Time & Fulfillment Details

Standard product orders typically have a lead time of 3-4 weeks from order confirmation. Customized solutions or large-volume projects may require 5-8 weeks, depending on complexity and material availability. We provide clear, transparent fulfillment schedules and work closely with our logistics partners to ensure timely and secure global delivery, offering various shipping options including FOB, CIF, or DDP.

Warranty Commitments

We stand behind the quality of our products with a comprehensive warranty. All 3d welded curved panel fence systems come with a 10-year anti-corrosion warranty on the galvanized and powder-coated finish, guaranteeing protection against manufacturing defects and premature coating failure under normal usage conditions. Structural integrity is guaranteed for 20 years.

Customer Support Information

Our dedicated customer support team is available to assist with all inquiries, from technical specifications and design consultation to order tracking and after-sales service. We offer multi-channel support via phone, email, and a dedicated online portal. For complex projects, on-site technical assistance can be arranged. We are committed to fostering long-term partnerships through exceptional service.

Conclusion and Authoritative References

The 3d welded curved panel fence represents the pinnacle of modern perimeter security, offering an optimal blend of strength, durability, aesthetic integration, and cost-effectiveness. Its advanced manufacturing process, adherence to rigorous international standards, and unparalleled adaptability through customized solutions make it the preferred choice for discerning B2B clients across diverse industries. By investing in this innovative fencing solution, organizations secure their assets with a system designed for longevity, minimal maintenance, and superior performance, thereby ensuring both operational continuity and peace of mind. We are dedicated to providing not just a product, but a comprehensive security partnership tailored to your specific needs.

References

- ISO 9001:2015 - Quality management systems – Requirements. International Organization for Standardization.

- ASTM A123/A123M-17 - Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products. ASTM International.

- ASTM B117-19 - Standard Practice for Operating Salt Spray (Fog) Apparatus. ASTM International.

- EN 10223-4:2012 - Steel wire and wire products for fencing and netting. Welded mesh fencing. European Committee for Standardization.

- Qualicoat - Quality Label for Lacquer, Paint and Powder Coatings on Aluminium for Architectural Applications. General Requirements.

-

3D Welded Wire Mesh Metal Fence Panels with Peach Post Rigid

NewsNov.17,2025

-

odm 7' security fence: Anti-Climb, Galvanized, 3D Panels

NewsNov.17,2025

-

4.7cm Hard PVC Privacy Strip+100 Clips, Chain-Link Fence, UV

NewsNov.17,2025

-

Powder-Coated Square Fence Posts – Decorative, Removable

NewsNov.17,2025

-

Chain Link Fence Temporary Fence - Durable, Secure, Fast

NewsNov.17,2025

-

Bike Storage Rack 1-6 Bicycle Floor Parking Stand, Durable

NewsNov.11,2025