Oct . 20, 2025 11:35 Back to list

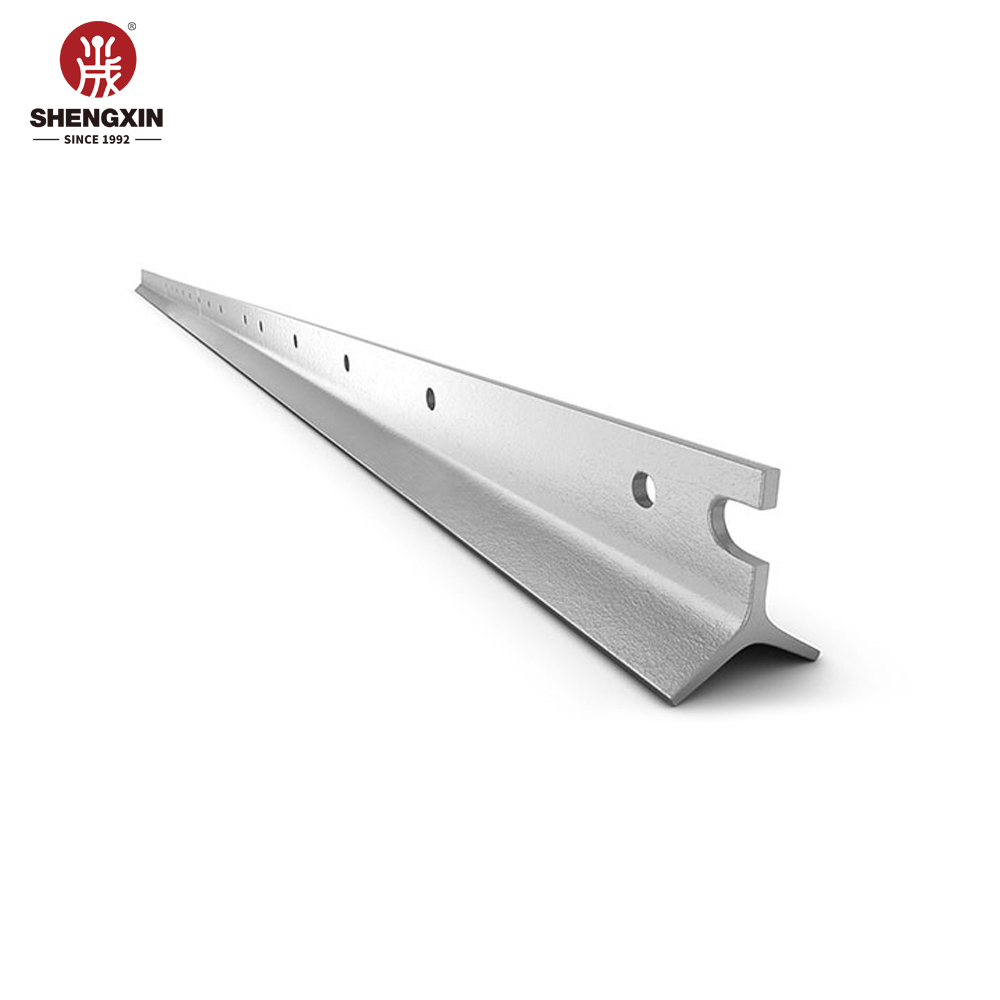

Australia Standard 2.04kg/m HDG Steel Star Picket Y Post

Australia’s go-to Y-post: rugged, recyclable, and ready for the paddock

Out in the field, not all fence posts are created equal. The Australia Standard 2.04kg/m Hot-dipped Galvanized Steel Star picket Y post has become something of a quiet standard—from wheat belts to peri-urban projects—because it balances durability, price, and installation speed. In fact, many customers say the first thing they notice is how “honest” these posts feel: straight, tough, consistent zinc coverage, and they bite into the soil cleanly.

Market snapshot and why this post is trending

Two forces are shaping demand: labor efficiency and lifecycle cost. Contractors want fast-driving posts with minimal call-backs, while station owners care about a 15–25+ year service life. Hot-dip galvanizing, to be honest, is carrying the reliability torch here. The Australia Standard 2.04kg/m Hot-dipped Galvanized Steel Star picket Y post hits that sweet spot—sturdy enough at 2.04 kg/m for real-world loads, yet not overbuilt or overpriced.

Materials and process flow (how it’s made)

- Base steel: Low-carbon steel (≈Q235/250 MPa yield), rolled into Y-profile for lateral stiffness.

- Punching: Pre-punched wire holes at regular intervals for plain wire, barbed, or mesh tie-offs.

- Tip forming: Sharpened/drawn point for easier driving in mixed soils.

- Hot-dip galvanizing: Full immersion per AS/NZS 4680; typical coating ≈85–100 µm (≈600–700 g/m²), real-world may vary by section thickness.

- QC tests: Coating thickness gauge checks, adhesion/bend, and periodic salt spray benchmarking (ASTM B117 reference).

Key specifications (typical)

| Profile | Y-section, ≈40–44 mm across flats |

| Weight | 2.04 kg/m (Australia standard class) |

| Lengths | 1.35 m, 1.50 m, 1.65 m, 1.80 m (others on request) |

| Zinc coating | ≈85–100 µm HDG, AS/NZS 4680; continuous options per AS/NZS 4792 where applicable |

| Holes/Studs | Pre-punched wire holes; notch/clip patterns vary by fence design |

| Service life | Inland C2–C3: ≈20–30 yrs; coastal C3–C4: ≈8–15 yrs (ISO 9223 guidance) |

| Origin | North of Houzhuang Village, Anping County, Hengshui, Hebei, China |

Where it shines

Rural fencing (sheep, cattle, boundary), orchard trellising, vineyard rows, temporary construction barriers, roadside exclusion, and even parklands. It’s an environmentally friendly picket—recyclable, recoverable after years—and, surprisingly, theft-resistant thanks to the profile and drive depth.

Vendor comparison (indicative)

| Vendor | Galv method | Coating mass | Lead time | Certs | Notes |

|---|---|---|---|---|---|

| This manufacturer (Anping) | HDG per AS/NZS 4680 | ≈600–700 g/m² | ≈2–4 weeks | ISO 9001 | Custom lengths/branding, export packing |

| Local hardware brand A | Mixed (HDG/painted) | ≈300–600 g/m² | In stock (varies) | Retail QC | Easy pickup; limited customization |

| Importer B | HDG/continuous | ≈450–650 g/m² | ≈4–6 weeks | ISO 9001 | Bulk-friendly; check coating spec carefully |

Customization and QC

- Lengths: 0.9–2.4 m; weight classes from ≈1.58 to 2.86 kg/m.

- Coating: HDG standard; optional powder/bitumen overcoat for coastal runs.

- Branding: Head embossing, color marks, pallet labeling for traceability.

- Testing: Thickness gauge logs, sampling to AS/NZS 4680; periodic ASTM B117 salt spray benchmarking.

Field note (case study)

A mixed-farming client near Dubbo swapped older painted pickets for the Australia Standard 2.04kg/m Hot-dipped Galvanized Steel Star picket Y post on a 6 km boundary. Crew reported 12–15% faster driving with fewer bent heads. After 18 months, zinc sheen remained intact, especially on the lee side—no red rust streaks. “Set and forget,” the foreman said, which is about the highest compliment you’ll hear onsite.

Why it’s a safe bet

Economical, recyclable, and—importantly—built to recognized galvanizing standards. From vineyards to highway fences, this post keeps wires tight and headaches low. I guess that’s why it’s quietly replacing concrete and bamboo stakes across so many projects.

Certifications and compliance

Manufacturing aligned to ISO 9001; galvanizing to AS/NZS 4680 and/or AS/NZS 4792 where applicable. Corrosivity planning per ISO 9223 helps you pick coating strategies for coastal versus inland sites.

References

- AS/NZS 4680: Hot-dip galvanized (zinc) coatings on fabricated ferrous articles.

- AS/NZS 4792: Hot-dip galvanized (zinc) coatings on ferrous hollow sections, applied by a continuous or specialized process.

- ISO 9223: Corrosion of metals and alloys — Corrosivity of atmospheres — Classification.

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus.

-

Comprehensive Guide to Chain Fence Link Sets: Benefits, Applications, and Trends

NewsNov.23,2025

-

Durable and Cost-Effective 2mm Chain Link Fence for Global Applications

NewsNov.22,2025

-

Durable & Cost-Effective Chain Link Metal Fence for Diverse Global Needs

NewsNov.22,2025

-

Comprehensive Guide to Lawn Chain Link Fence: Durability, Applications, & Innovations

NewsNov.21,2025

-

Powder Coated Double Wire Mesh Fence - Anping Shengxin

NewsNov.21,2025

-

Chain Link Fence System — Durable, Versatile, and Cost-Effective Fencing Solutions Worldwide

NewsNov.20,2025