Oct . 26, 2025 11:25 Back to list

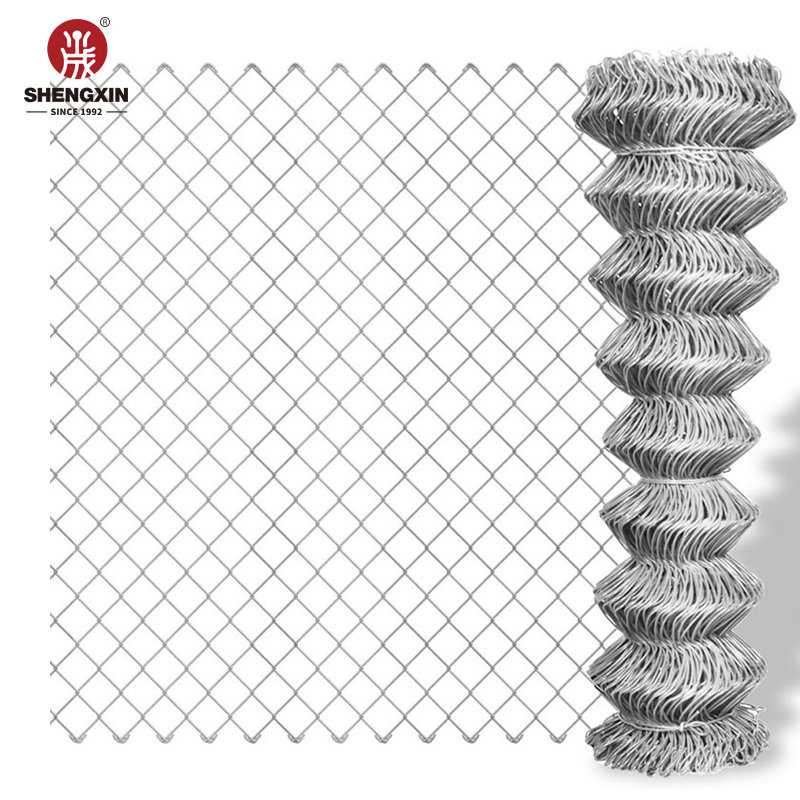

Chain Link Fencing Wire – Durable, Galvanized, Bulk Supply

Field Notes on Chain Link Fencing: What’s Working Now (and Why)

When people ask me about Chain Link Fencing Wire, I don’t answer with buzzwords; I think about crews on site, salt in the air, and budgets that still have to add up. This Powder Coated / Hot Dipped Ganvanized Chain Link Fence Mesh comes out of North of Houzhuang Village, Anping County, Hengshui City, Hebei Province, China—an area that’s been weaving wire longer than some brands have existed. And yes, it shows.

What’s trending in fences (that actually matters)

- Powder-coated greens and blacks are winning bids—less glare, tidier lines.

- Anti-climb meshes (50×50 or tighter) for utilities and logistics perimeters.

- Zinc-aluminum (Galfan-type) coatings for longer life, especially near coasts.

- Privacy add-ons: slats and windscreens, surprisingly popular at schools.

Process, materials, and testing (the nuts and bolts)

Material: low‑carbon steel wire (often Q195), drawn to size, then either zinc-coated (EN 10244‑2 Class D/E) or hot‑dip galvanized after weaving (ISO 1461). Powder coat uses an electrostatic spray over pretreated zinc, baked for adhesion.

Methods: chain-link weaving, knuckle/knuckle or twist/knuckle edge, tension bar + brace + top rail system. I’ve seen consistent welds on posts and clean bends on rails—small details that speed installs.

Testing we look for: ASTM A392/A641 zinc mass, ISO 9227 salt spray, ISO 2178 coating thickness, ASTM D3359 adhesion (powder), and tensile per ASTM A641. In real-world use, inland service life is ≈15–20 years for HDG, ≈18–25 years for zinc + powder; coastal sites vary—plan maintenance accordingly.

Key specifications

| Parameter | Options / Notes |

|---|---|

| Wire Diameter | 2.8, 3.0, 3.2, 3.5, 4.0 mm |

| Mesh Size | 50×50, 60×60, 75×75 mm (others on request) |

| Height | 1.2, 1.5, 1.8, 2.0, 2.4 m |

| Roll Length | ≈9–18 m (depends on roll weight) |

| Posts | 75×1.5/2.0; 60×1.5/2.0; 48×1.5/2.0 mm |

| Top Rail | 48×1.2/1.5; 40×1.2/1.5; 32×1.2/1.5 mm |

| Finish | Hot-dipped galvanized or powder-coated over zinc |

| Zinc Mass | ≈200–275 g/m² (ASTM/EN class dependent) |

Where it excels

Chain Link Fencing Wire makes sense for schools, sports courts, substations, solar farms, warehouses, farms, and temporary work zones. Many customers say install speed and easy tensioning beat panel systems when terrain is uneven. I guess that’s why crews keep asking for it.

Vendor landscape (quick compare)

| Vendor Type | Pros | Watch-outs | Typical |

|---|---|---|---|

| Anping OEM mill | Best price, full customization, fast tooling | QC varies—ask for test sheets | MOQ: 500–1,000 m; Lead: 10–20 days |

| Trading house | Sourcing flexibility, mixed loads | Adds margin, specs can drift | Price: mid; Lead: 15–30 days |

| Big-brand distributor | Stock on hand, warranty, install guides | Highest price, fewer custom sizes | Price: high; Lead: ex-stock/short |

Customization tips

- Specify edge type (K/K or T/K) and tension bar thickness—installers will thank you.

- Go 50×50 mm mesh near public areas; 60×60 mm is fine for general perimeters.

- Coastal? Pick heavier zinc or Zn‑Al wire, then powder coat. Real-world life jumps.

Mini case notes

Logistics park, Rotterdam: 2.4 m, 50×50, powder-coated green. Passed 500+ hours ISO 9227 lab check; maintenance calls dropped year-on-year. School in Melbourne: black 1.8 m with privacy slats; principal said “blends better, kids don’t climb.” Desert solar farm, UAE: HDG with Zn‑Al wire; no coating flake after first monsoon season, according to the site crew.

Compliance and paperwork

Ask for: mill certs, zinc mass report (ASTM A392 or EN 10244‑2), powder adhesion (ASTM D3359), thickness (ISO 2178), and salt spray (ISO 9227). Many mills carry ISO 9001; third-party inspections (e.g., SGS) are common. Installation should follow ASTM F567 or local equivalents. To be honest, the paperwork often predicts the outcome.

Bottom line: Chain Link Fencing Wire remains a cost-efficient perimeter workhorse. The newer powder systems and Zn‑Al wires make it tougher, prettier, and, frankly, easier to own.

Authoritative references

- ASTM A392/A392M – Zinc-Coated Steel Chain-Link Fence Fabric.

- ASTM F567 – Installation of Chain-Link Fence.

- EN 10244-2 – Steel wire and wire products, Zn/Zn‑Al coatings.

- ISO 1461 – Hot dip galvanized coatings on fabricated iron and steel.

- ISO 9227 – Corrosion tests in artificial atmospheres (salt spray).

- ASTM D3359 – Measuring adhesion by tape test (powder coatings).

- ASTM A641/A641M – Zinc-Coated (Galvanized) Carbon Steel Wire.

-

Fancy Chain Link Fence – Durable, Stylish, and Sustainable Fencing Solutions

NewsNov.24,2025

-

Comprehensive Guide to Chain Fence Link Sets: Benefits, Applications, and Trends

NewsNov.23,2025

-

Durable and Cost-Effective 2mm Chain Link Fence for Global Applications

NewsNov.22,2025

-

Durable & Cost-Effective Chain Link Metal Fence for Diverse Global Needs

NewsNov.22,2025

-

Comprehensive Guide to Lawn Chain Link Fence: Durability, Applications, & Innovations

NewsNov.21,2025

-

Powder Coated Double Wire Mesh Fence - Anping Shengxin

NewsNov.21,2025