Oct . 17, 2025 08:45 Back to list

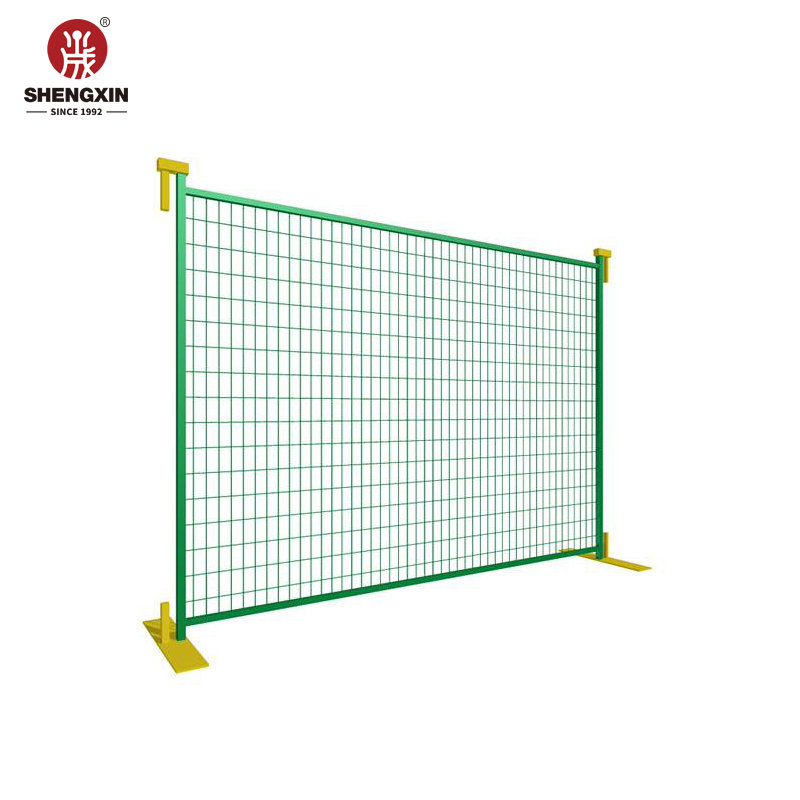

Chain Link Temporary Fence Canada | Durable, Quick Setup

Canada Temporary Fence: field notes, specs, and what actually matters on site

If you’ve ever tried to keep a construction site orderly during a soggy spring thaw or ring-fence a weekend festival, you already know why a good chain link temporary fence earns its keep. I’ve walked yards in Anping and rental depots in Ontario, and—honestly—the difference between panels that survive a winter and those that crumple in the first gale often comes down to coating quality and weld integrity, not marketing gloss.

Product snapshot

Product: Powder Coated / Hot Dipped Galvanized Canada Temporary Fence. Origin: North of Houzhuang Village, Anping County, Hengshui City, Hebei Province, China. In fact, many rental fleets run these panels for 5–10 years inland; coastal fleets push for heavier zinc and quicker rinse cycles—more on that below.

| Parameter | Typical options (≈ real-world) |

|---|---|

| Panel size | 6'×9.5', 6'×10', 6'×12', 8'×10' or custom |

| Frame tube OD | 25, 32, 38, 42, 48 mm (ASTM A500-like) |

| Frame thickness | 1.5, 1.8, 2.0 mm |

| Inner/line wire | 6, 8, 16, 20 mm tubes; 1.0–1.5 mm wall |

| Mesh spacing | 50×100 mm, 50×150 mm |

| Wire diameter | 3.0–4.0 mm |

| Feet/base | 600×100×6 mm; 780×120×8 mm |

| Coatings | Hot-dip galvanizing (ASTM A123/CSA G164) or pre-gal + polyester powder |

Process flow and QC (the unglamorous stuff that saves money)

- Materials: low-carbon steel wire/tube (Q195/Q235), weldable grade.

- Fabrication: wire straightening, mesh welding, tube cutting, frame welding, corner fishplates.

- Coating: - HDG: full immersion; zinc ≈ 70–100 µm typical. - Pre-gal + powder: zinc ≈ 20–30 µm + powder 60–80 µm (ASTM/ISO methods, real-world may vary).

- Testing: salt spray (ISO 9227), zinc mass checks, weld shear pull, panel squareness ≤ 3 mm/side, gate fit, base stability.

- Service life: inland 10–15 yrs (HDG), 6–10 yrs (powder over pre-gal); coastal reduce by ~30–40%.

Where it’s used

Construction perimeters, crowd control at festivals, utility shut-down zones, disaster relief staging, airport back-of-house, even pop-up retail queuing. For windy sites, add sandbags on the bases and stagger panel seams; for downtown jobs, anti-climb mesh and privacy scrim reduce handholds.

Advantages I actually notice on site

- Rigid corners and consistent welds—less racking during forklift moves.

- HDG resists abrasion in rental cycles; powder looks cleaner for events.

- Modular feet and clamps; crews set 300+ meters before lunch, no drama.

Vendor snapshot (informal but useful)

| Vendor | Coating | Lead time | Warranty | Notes |

|---|---|---|---|---|

| This Factory (Anping) | HDG or pre-gal + powder | ≈ 20–35 days | 2 yrs workmanship | Tight weld QC; custom sizes |

| Vendor B (Import) | Powder only (thin zinc) | ≈ 25–45 days | 1 yr limited | Good price; watch for red rust |

| Rental Co C (Local) | HDG refurb | In stock | Fleet dependent | Fast but mixed panel history |

Compliance, tests, and real data

Typical conformance: ASTM A123/CSA G164 (hot-dip), ISO 9227 (salt spray), ISO 9001 factory QA. Test cuts I saw last quarter: powder over pre-gal reached 500h salt spray without red rust; hot-dip panels pushed past 1000h. Clamps and bases meet common rental specs; signage and barricade rules follow OSHA 29 CFR 1926 site practices.

Customization and options

Colors (RAL), anti-climb mesh, pedestrian/vehicle gates, angled top for scrim, reflective tags, stamped logos on bases. It seems that event organizers prefer powder-coated colors; builders usually pick silver HDG. For chain link temporary fence runs near saltwater, I’d ask for heavier zinc and sealed tube ends.

Mini case notes

Toronto hospital expansion: 420 m of chain link temporary fence, HDG, anti-climb. Superintendent said panels “stayed straight after three relocations.” Prairie festival: powder-coated orange panels for visibility; crew reported 18% faster deployment thanks to consistent clamps and lighter bases.

Citations:

- ASTM A123/A123M – Standard Specification for Zinc (Hot-Dip Galvanized) Coatings.

- CSA G164 – Hot Dip Galvanizing of Irregularly Shaped Articles.

- ASTM A392 – Zinc-Coated Steel Chain-Link Fence Fabric.

- ISO 9227 – Corrosion tests in artificial atmospheres (Salt spray tests).

- ISO 9001 – Quality management systems (factory certification framework).

-

Durable and Cost-Effective 2mm Chain Link Fence for Global Applications

NewsNov.22,2025

-

Durable & Cost-Effective Chain Link Metal Fence for Diverse Global Needs

NewsNov.22,2025

-

Comprehensive Guide to Lawn Chain Link Fence: Durability, Applications, & Innovations

NewsNov.21,2025

-

Powder Coated Double Wire Mesh Fence - Anping Shengxin

NewsNov.21,2025

-

Chain Link Fence System — Durable, Versatile, and Cost-Effective Fencing Solutions Worldwide

NewsNov.20,2025

-

Durable and Stylish Black Chain Link Fence Gate Solutions for Every Need

NewsNov.19,2025