Oct . 21, 2024 13:55 Back to list

Manufacturers of Chain Link Fence Components and Parts for Various Applications

The Importance of Chain Link Fence Part Factories A Closer Look

In today's world where security and property demarcation have become increasingly critical, chain link fences have emerged as a popular choice for both residential and commercial properties. These fences are not only durable and cost-effective but also versatile, serving various applications from backyards to sports complexes. Behind this ubiquitous fencing solution lies a complex web of manufacturing processes, particularly the essential factories that produce chain link fence parts.

Understanding Chain Link Fences

A chain link fence consists of several components, including the mesh fabric, posts, rails, fence fittings, and gates. The mesh is typically made from galvanized steel wire, which is resistant to rust and corrosion. The posts and rails support the fence’s structure, while fittings provide the necessary hardware to connect all the elements securely. Each component plays a vital role in ensuring that the fence is not only functional but also aesthetically pleasing.

The Role of Part Factories

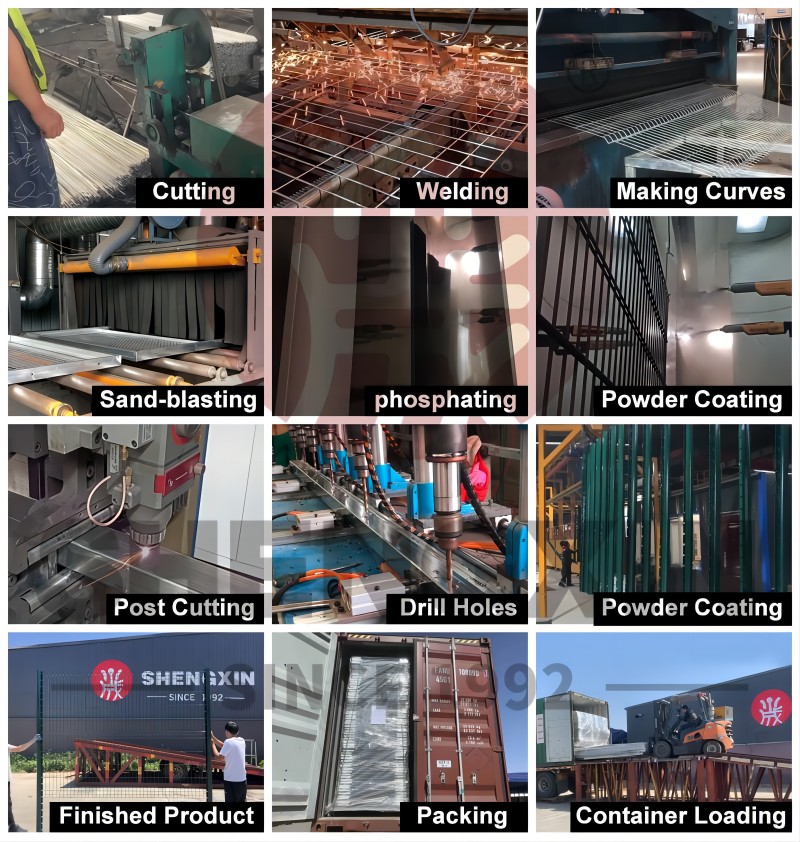

Manufacturing chain link fence parts involves specialized factories equipped with advanced machinery and skilled labor. These factories are integral to producing high-quality components that meet industry standards. For instance, the production of galvanized wire requires a process called wire drawing, where metal rods are drawn through progressively smaller dies to produce thinner wires. These wires are then treated to create a protective zinc coating, enhancing their longevity.

Moreover, the fabrication of posts and rails often involves processes such as cutting, bending, and welding. Factories utilize automated machinery to ensure precision and efficiency in production, yielding a consistent product that can withstand various environmental conditions.

Quality Control and Industry Standards

Ensuring the quality of chain link fence parts is paramount, as any failure in the components can compromise the fence's integrity. Reputable factories adhere to strict quality control measures and industry standards. This includes inspections at various stages of production, from raw material assessment to final product testing. Compliance with standards set by organizations such as the American Society for Testing and Materials (ASTM) ensures that the products meet the requirements for strength, durability, and performance.

chain link fence part factories

By investing in quality manufacturing processes and rigorous testing, factories not only enhance customer satisfaction but also contribute to the overall reputation of chain link fences in the market

.Innovation and Customization

As technology evolves, so does the manufacturing landscape for chain link fence parts. Factories are increasingly adopting automation and advanced technologies such as computer numerical control (CNC) machines, which allow for greater precision and efficiency. These innovations enable the production of customized components tailored to specific customer needs. Whether it’s unique dimensions, specialized coatings, or different wire gauges, factories can now meet diverse specifications while maintaining quality.

In addition to customization, sustainable practices are gaining traction within the industry. Many factories are exploring eco-friendly materials and recycling options for scrap metal. This commitment to sustainability not only reduces waste but also appeals to environmentally conscious consumers.

The Future of Chain Link Fence Part Manufacturing

Looking ahead, the future of chain link fence part factories appears promising. As urban development accelerates and security concerns grow, the demand for chain link fences is expected to rise. Factories that embrace innovation and sustainability will likely lead the charge in meeting this demand.

Moreover, as e-commerce continues to expand, factories may explore direct-to-consumer sales avenues, enabling easier access for homeowners and contractors. This shift could revolutionize how fencing materials are sold and installed, making it more convenient for consumers.

Conclusion

Chain link fence part factories play a crucial role in the fencing industry, ensuring that high-quality components are readily available to meet the demands of a growing market. Through advanced manufacturing techniques, rigorous quality control, and a commitment to innovation, these factories are not only shaping the future of fencing solutions but also enhancing the safety and security of properties worldwide. As we continue to evolve in our construction and security needs, the importance of these factories will undoubtedly remain paramount.

-

Premium ODM 7' Security Fence - High-Security & Durable

NewsAug.01,2025

-

Powder Coated Double Wire Mesh Fence for Germany Market - Anping County Shengxin Metal Products Co., Ltd.

NewsJul.31,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd.|Durable, Corrosion-Resistant, Customizable

NewsJul.31,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd | Durable Corrosion Resistant Fencing

NewsJul.31,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd | Durability, Corrosion Resistance

NewsJul.31,2025

-

Privacy Chain Link Fence Slats | Durable Solutions

NewsJul.31,2025