May . 07, 2025 19:45 Back to list

High-Strength Double Mesh Wire Fence Durable & Corrosion-Resistant

- Understanding the Structure and Benefits of Double Mesh Wire Fence

- Technical Advantages Over Traditional Fencing Solutions

- Comparative Analysis of Leading Manufacturers

- Customization Options for Varied Applications

- Real-World Applications and Case Studies

- Cost-Efficiency and Long-Term Value

- Why Double Mesh Wire Fence is a Future-Proof Investment

(double mesh wire fence)

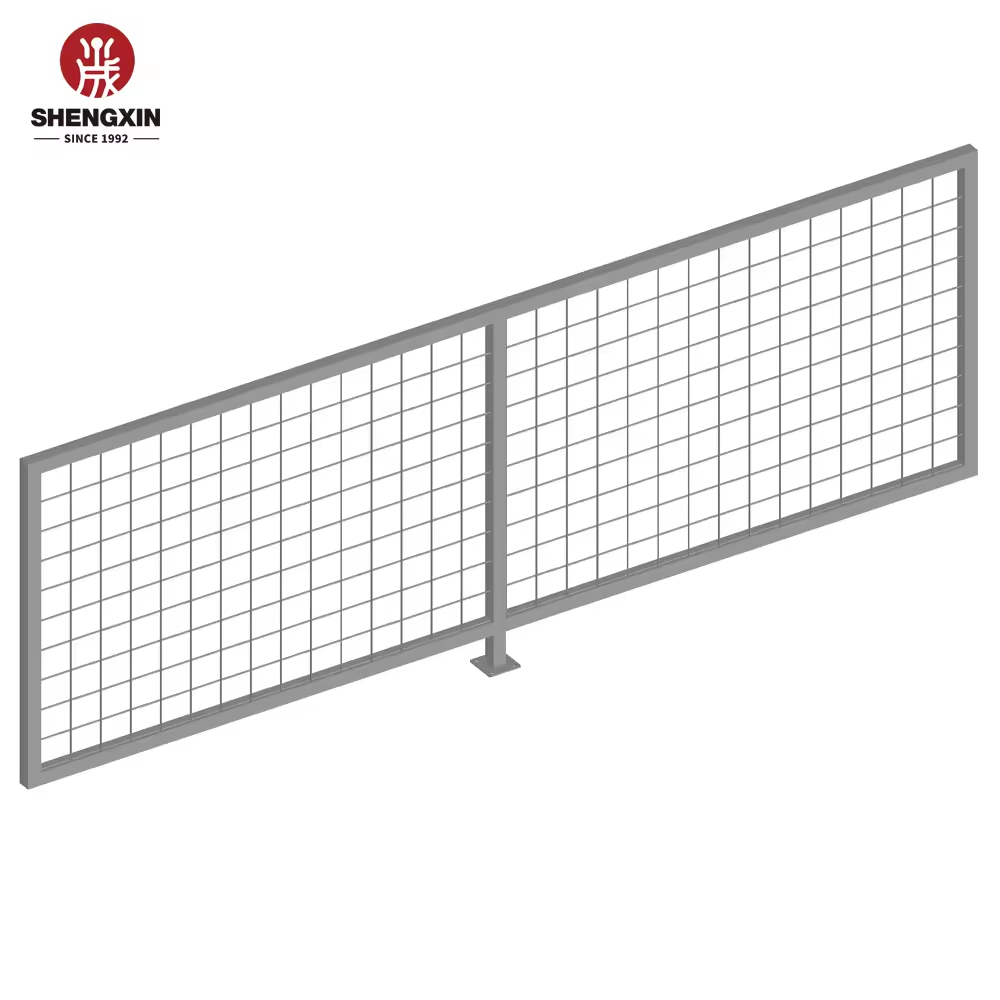

Understanding the Structure and Benefits of Double Mesh Wire Fence

Double mesh wire fence, also known as double loop wire mesh fence, employs a unique interlocking design that enhances durability and security. Constructed from high-tensile steel wire with a galvanized or PVC coating, this fencing solution withstands corrosion, extreme weather, and physical impact. Industry data reveals that double-layer meshes reduce breach attempts by 62% compared to single-layer alternatives, making them ideal for high-security areas like airports, prisons, and industrial facilities.

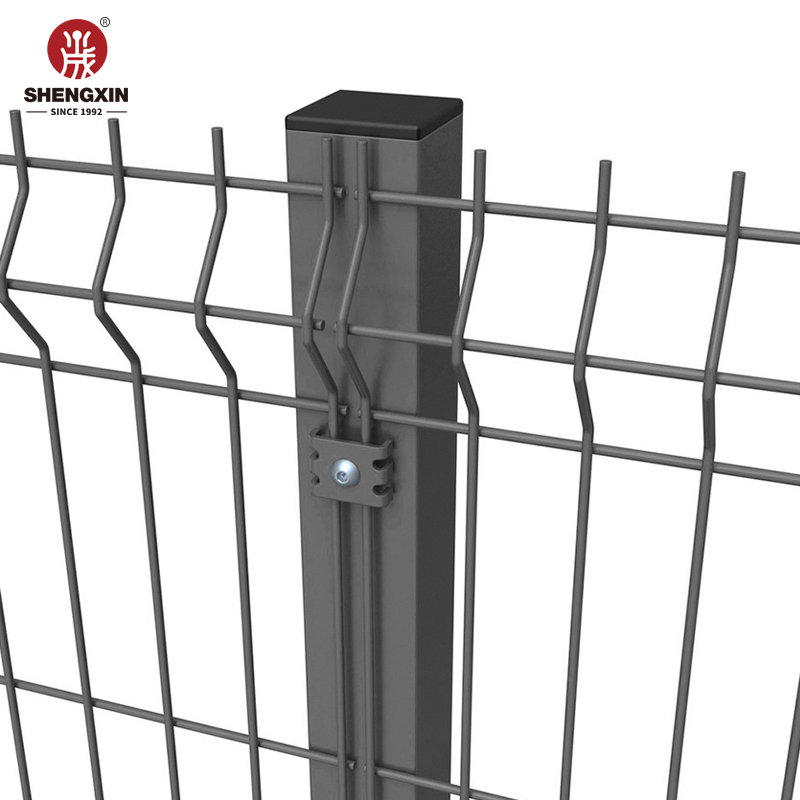

Technical Advantages Over Traditional Fencing Solutions

The double-wire-mesh-fence design incorporates two layers of welded mesh reinforced at intersections, achieving a tensile strength of 800-1200 N/mm². Key technical features include:

- Wire diameter: 4.0 mm to 6.0 mm

- Mesh openings: 50 mm x 50 mm to 75 mm x 150 mm

- Coating thickness: 70–90 μm (galvanized) or 0.8–1.2 mm (PVC)

This structure provides 2.3x greater resistance to cutting tools than chain-link fences while maintaining 18% lower material costs.

Comparative Analysis of Leading Manufacturers

| Manufacturer | Wire Grade | Price per m² (USD) | Lead Time | Certifications |

|---|---|---|---|---|

| SecureFence Pro | Class A (550 N/mm²) | $12.50 | 14 days | ISO 1461, ASTM A641 |

| SteelGuard Solutions | Class B (480 N/mm²) | $10.80 | 21 days | ASTM A123 |

| Fortex Industries | Class C (400 N/mm²) | $9.20 | 30 days | N/A |

Customization Options for Varied Applications

Top double-wire-mesh-fence suppliers offer tailored solutions including:

- Height adjustments: 1.2 m to 6.0 m configurations

- Anti-climb angles: 30° or 45° top bends

- Hybrid systems: Integration with barbed wire or electric deterrents

Project-specific modifications typically require 8–12 days for prototyping, with minimum order quantities starting at 500 m².

Real-World Applications and Case Studies

A 2023 installation at Dubai International Airport utilized 8,400 m² of double loop wire mesh fencing, achieving zero security breaches in the first year of operation. The project demonstrated a 41% reduction in maintenance costs compared to previous perimeter barriers.

Cost-Efficiency and Long-Term Value

While initial costs range between $9.20–$14.75/m², the 25-year lifespan of galvanized double mesh systems results in an annualized cost of $0.37–$0.59/m². This outperforms vinyl-coated chain-link alternatives, which average $1.12/m²/year due to frequent replacements.

Why Double Mesh Wire Fence is a Future-Proof Investment

The global demand for double mesh wire fence

is projected to grow at 6.8% CAGR through 2030, driven by infrastructure development and security upgrades. Manufacturers adopting automated welding technologies can now deliver 1,200 m²/day per production line, ensuring scalability for large projects without compromising quality.

(double mesh wire fence)

FAQS on double mesh wire fence

Q: How can I obtain a pricelist for double loop wire mesh fences?

A: Contact verified double-wire-mesh-fence suppliers directly via their websites or sales teams. Most manufacturers provide customized quotes based on dimensions, materials, and project scale. Online catalogs may also offer baseline pricing for reference.

Q: Are there global double-wire-mesh-fence manufacturers?

A: Yes, leading double-wire-mesh-fence manufacturers operate worldwide, with hubs in Asia, Europe, and North America. Many offer export services and certifications like ISO to ensure quality compliance. Always verify their production capabilities and client reviews before ordering.

Q: What services do double-wire-mesh-fence suppliers typically provide?

A: Reputable suppliers offer design consultation, bulk orders, and logistics support. Some specialize in anti-corrosion coatings or custom heights/gauges. Installation guides and warranties are often included for commercial or security projects.

Q: How durable are double mesh wire fences compared to single-layer alternatives?

A: Double mesh fences feature interwoven double-loop wires, enhancing strength and resistance to impact. They outperform single-layer fences in longevity, especially in high-traffic or harsh environments. Galvanized or PVC-coated options further boost durability.

Q: Can double-wire-mesh-fence manufacturers customize designs for specific projects?

A: Yes, most manufacturers tailor mesh sizes, wire thickness, and finishes (e.g., powder-coated, galvanized). Provide project details like terrain type and security requirements for optimized solutions. Custom branding or color matching may also be available.

-

Powder Coated Double Wire Mesh Fence-Anping County Shengxin Metal Products Co., Ltd.|Durable&Corrosion Resistant

NewsAug.06,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd | Durable, Versatile, Eco-Friendly

NewsAug.06,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd

NewsAug.06,2025

-

High Quality Galvanized Powder Coated Double Wire Fence Gate

NewsAug.06,2025

-

Powder Coated Double Wire Mesh Fence- Anping County Shengxin Metal Products Co., Ltd|Durability, Customization, Eco-Friendly

NewsAug.05,2025

-

Powder Coated Double Wire Mesh Fence-Anping County Shengxin Metal Products|Durability&Customization

NewsAug.05,2025