Sep . 10, 2025 08:40 Back to list

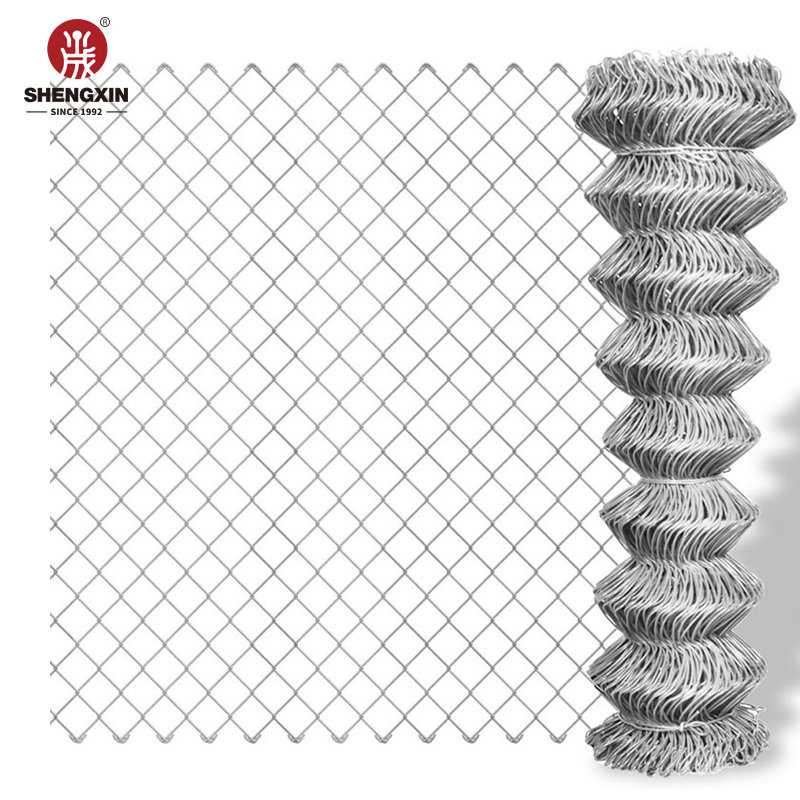

Durable Chain Link Fencing Wire | Secure Mesh for Various Needs

Industry Trends and Market Dynamics for Advanced Fencing Solutions

The global market for perimeter security and industrial fencing solutions continues its robust expansion, driven by increasing demands for infrastructure protection, asset safeguarding, and boundary demarcation across various sectors. Within this landscape, chain link fencing wire stands as a cornerstone technology, valued for its cost-effectiveness, versatility, and durability. Current industry trends highlight a significant shift towards enhanced material science, advanced coating applications, and intelligent integration with broader security systems. There's a growing preference for solutions that offer extended service life, minimal maintenance requirements, and superior resistance to environmental degradation. Furthermore, the demand for customizable solutions, capable of meeting specific project parameters and regulatory compliance, is escalating, making products like our Powder Coated / Hot Dipped Galvanized Chain Link Fence Mesh increasingly critical for B2B procurement specialists and project engineers.

Technological advancements in metallurgy and surface treatment are paving the way for next-generation chain link fencing wire products. Innovations include specialized alloys for increased tensile strength, multi-layer coating systems that offer synergistic protection against corrosion and UV radiation, and precision weaving techniques that ensure consistent mesh integrity. The market also sees a rising demand for sustainable manufacturing practices, with a focus on energy efficiency and recyclable materials. This evolution underscores the importance of partnering with manufacturers who not only adhere to stringent quality standards but also invest in R&D to deliver solutions that are future-proof and aligned with global environmental initiatives.

Manufacturing Process of High-Performance Chain Link Fencing Wire

The production of our Powder Coated / Hot Dipped Galvanized Chain Link Fence Mesh involves a meticulously controlled, multi-stage process designed to ensure superior quality, durability, and performance. Our commitment to ISO 9001 certified manufacturing protocols guarantees consistency and reliability from raw material sourcing to final product inspection.

Detailed Process Flow:

- Raw Material Procurement & Inspection: We source high-grade steel wire rods, primarily low carbon steel or galvanized steel, adhering to ASTM A853 standards. Each batch undergoes rigorous chemical composition analysis and mechanical property testing (tensile strength, yield strength) to ensure it meets our exacting specifications before further processing.

- Wire Drawing: The steel wire rods are drawn through a series of dies to achieve the precise wire gauge required for the chain link fencing wire. This cold-drawing process increases the wire's tensile strength and improves its surface finish, crucial for subsequent coating adherence.

- Galvanization (for HDG variant): For hot-dipped galvanized mesh, the drawn wire is pre-cleaned (degreasing, pickling, fluxing) and then immersed in a bath of molten zinc at approximately 450°C. This creates a metallurgical bond, forming multiple layers of zinc-iron alloy and a pure zinc outer layer, providing sacrificial and barrier corrosion protection according to ASTM A392 or EN 10244-2 standards.

- Weaving/Knitting: Specialized chain link weaving machines intertwine the galvanized or plain steel wires into the distinctive diamond pattern. The wires are fed into the machine, twisted, and then interlocked with adjacent wires, forming a continuous mesh. Precision weaving ensures uniform mesh size and tension across the entire roll.

- Pre-treatment (for Powder Coated variant): For powder-coated chain link fencing wire, the woven mesh undergoes a multi-stage pre-treatment process, including degreasing, rinsing, iron phosphate conversion coating, and final rinsing. This prepares the surface for optimal powder adhesion and enhances corrosion resistance.

- Powder Coating: Electrostatic spray guns apply thermosetting polymer powder (e.g., polyester, epoxy-polyester) to the pre-treated mesh. The mesh then passes through a curing oven, where the powder melts and chemically cross-links, forming a durable, uniform, and aesthetically pleasing protective layer. This process adheres to AAMA 2603/2604 standards.

- Quality Control & Testing: Throughout the entire process, stringent quality control checks are performed. This includes visual inspection for defects, dimensional checks (mesh size, wire diameter, roll length), coating thickness measurement (for both zinc and powder), adhesion testing (cross-hatch test for powder coating), and salt spray corrosion resistance testing (ASTM B117) to evaluate service life and environmental resilience.

- Packaging & Dispatch: Finished rolls of chain link mesh fence are securely packaged, often with protective wraps, and prepared for shipping, ensuring they arrive at your site in pristine condition.

This meticulous production chain ensures that our products, including the Powder Coated / Hot Dipped Galvanized Chain Link Fence Mesh, deliver exceptional longevity, often exceeding 20-25 years in various environments. Target industries include petrochemical, metallurgy, power generation, water supply & drainage, agriculture, and general infrastructure projects, where corrosion resistance and robust security are paramount.

Technical Specifications and Performance Parameters

Understanding the precise technical specifications of chain link fencing wire is crucial for engineers and procurement managers to ensure optimal performance and compliance with project requirements. Our Powder Coated / Hot Dipped Galvanized Chain Link Fence Mesh is manufactured to stringent international standards, offering reliability and consistent quality.

Standard Product Specification Table:

| Parameter | Hot Dipped Galvanized (HDG) | Powder Coated (PC) |

|---|---|---|

| Material | Low Carbon Steel Wire (Q195/Q235) | Low Carbon Steel Wire (Q195/Q235) |

| Wire Diameter | 2.0mm - 5.0mm (12 - 6 SWG) | 2.5mm - 4.5mm (PVC Coated overall) |

| Mesh Size (Diamond) | 40x40mm, 50x50mm, 60x60mm, 70x70mm | 50x50mm, 60x60mm, 75x75mm |

| Fence Height | 1.0m - 4.0m (customizable) | 1.2m - 3.0m (customizable) |

| Roll Length | 10m - 50m (standard), up to 100m | 10m - 30m (standard) |

| Zinc Coating Weight | >200 g/m² (ASTM A392 Class 1) | Pre-galvanized or electro-galvanized base |

| Powder Coating Thickness | N/A | >80 microns (AAMA 2603/2604) |

| Tensile Strength | 340-550 MPa (approx.) | 340-550 MPa (approx.) |

| Color Options | Silver/Grey (Natural Zinc Finish) | RAL colors (e.g., Green RAL 6005, Black RAL 9005) |

These specifications highlight our product's suitability for demanding environments, emphasizing the robust protection offered by both hot-dipped galvanization and advanced powder coating. The high tensile strength ensures structural integrity and resistance to impact, while customizable dimensions provide flexibility for diverse project scopes.

Technical Advantages and Performance Benchmarks

Our Powder Coated / Hot Dipped Galvanized Chain Link Fence Mesh offers distinct technical advantages that set it apart in the industrial fencing market. These benefits translate directly into superior long-term value and operational efficiency for our clients.

- Unparalleled Corrosion Resistance: The Hot Dipped Galvanized (HDG) variant boasts a thick, metallurgically bonded zinc layer (typically >200 g/m²), providing sacrificial and barrier protection against rust and corrosion, even in harsh industrial or coastal environments. The Powder Coated (PC) version, often applied over a galvanized base, adds an additional layer of robust polymer protection, making it virtually impervious to corrosive agents, UV radiation, and abrasion. This extends the service life significantly, reducing the need for premature replacement.

- High Tensile Strength & Security: Manufactured from high-quality steel, our chain link mesh fence exhibits superior tensile strength (340-550 MPa), offering robust physical security against unauthorized access, impacts, and vandalism. The interwoven pattern provides flexibility while maintaining structural integrity, making it difficult to cut or climb without specialized tools.

- Low Maintenance & Cost-Effectiveness: The advanced coating systems minimize the need for painting, rust treatment, or other routine maintenance, significantly reducing operational expenditures over the fence's lifespan. This long-term cost-effectiveness makes it an economical choice for large-scale industrial and commercial projects, especially for those considering wholesale chain link fence purchases.

- Versatility & Adaptability: Available in a wide range of wire gauges, mesh sizes, and heights, our chain link fencing wire can be tailored to various application requirements. The flexible nature of the mesh allows it to adapt to uneven terrains and curves, facilitating easier installation compared to rigid fencing systems.

- Environmental Resilience: Engineered to withstand extreme temperatures, harsh chemicals, and aggressive atmospheric conditions, these fences maintain their aesthetic and structural properties under diverse environmental stressors.

Diverse Application Scenarios and Industries Served

The inherent strength, durability, and adaptability of our Powder Coated / Hot Dipped Galvanized Chain Link Fence Mesh make it an ideal solution across a broad spectrum of industrial and commercial applications. Its ability to provide robust perimeter security and demarcation is leveraged in critical infrastructure and high-traffic areas alike.

- Petrochemical and Energy Facilities: Critical for securing refineries, power plants, solar farms, and gas pipelines, where perimeter integrity is paramount to prevent unauthorized access and ensure operational safety. The corrosion resistance is vital in environments exposed to chemicals and harsh weather.

- Industrial Parks and Manufacturing Plants: Used for property demarcation, controlled access zones, and securing valuable assets within large industrial complexes. The low maintenance aspect is a significant advantage for sprawling sites.

- Mining and Metallurgy Operations: Providing robust enclosures for equipment yards, storage areas, and hazardous zones within mining and metallurgical sites, offering resistance against heavy-duty industrial conditions.

- Water Treatment Plants and Utilities: Essential for securing reservoirs, pumping stations, and water treatment facilities, protecting vital public infrastructure from tampering and contamination. The long service life minimizes disruptions.

- Transportation Infrastructure: Deployed along highways, railways, airports, and port facilities to manage access, prevent trespass, and contain wildlife, ensuring safety and operational continuity.

- Commercial and Retail Properties: Securing warehouses, distribution centers, and large retail outlets, offering a balance of security, visibility, and cost-effectiveness.

- Agricultural and Livestock Enclosures: While heavy-duty, it's also used for robust animal containment and property protection on large agricultural estates.

In these scenarios, our chain link fencing wire demonstrates advantages such as energy saving (through reduced maintenance needs), superior corrosion resistance, and high adaptability to varying topographies.

Vendor Selection and Product Comparison

Selecting the right supplier for wholesale chain link fence solutions is a critical decision for B2B clients, impacting project timelines, budget, and long-term performance. Key differentiators among vendors often lie in material quality, manufacturing precision, coating technology, and post-sales support.

Key Considerations for Vendor Comparison:

- Certifications & Compliance: Verify adherence to international standards like ISO 9001, ASTM (American Society for Testing and Materials), and EN (European Standards) for materials and coatings.

- Material Traceability: A reputable vendor provides clear documentation on raw material sourcing and quality control at each production stage.

- Coating Quality: Scrutinize zinc coating weight for HDG products and coating thickness/adhesion tests for powder-coated variants. Inferior coatings drastically reduce service life.

- Customization Capabilities: Assess a vendor's ability to provide non-standard dimensions, colors, or specific wire gauges to meet unique project specifications.

- Lead Times & Logistics: Reliable lead times and efficient global logistics are crucial for project scheduling and minimizing downtime.

- Warranty & Support: A strong warranty and responsive customer support reflect confidence in product quality and commitment to client satisfaction.

Product Comparison: Our Offering vs. Standard Market Alternatives

| Feature | Our Powder Coated / HDG Chain Link | Basic Galvanized Chain Link (Market Std.) |

|---|---|---|

| Corrosion Protection | Dual-layer (Zinc + Powder Coat) or Heavy HDG (>200 g/m²) | Standard HDG (~60-80 g/m²) or Electro-Galvanized |

| Service Life Expectancy | 20-25+ years (depending on environment) | 5-15 years (depending on environment) |

| Aesthetics | Variety of RAL colors, smooth finish, modern look | Typical silver/grey zinc finish |

| Maintenance Requirements | Very Low (periodic cleaning only) | Moderate (potential for rust treatment/repainting) |

| Environmental Suitability | Harsh industrial, coastal, high UV environments | Mild to moderate environments |

This comparison underscores the superior value proposition of our specialized chain link fencing wire solutions. While the initial investment might be slightly higher, the long-term savings in maintenance and replacement costs, coupled with enhanced durability and aesthetic appeal, provide a significantly better return on investment.

Customized Solutions and Design Flexibility

Recognizing that no two projects are identical, we offer extensive customization capabilities for our Powder Coated / Hot Dipped Galvanized Chain Link Fence Mesh. Our engineering team collaborates closely with clients to develop bespoke solutions that precisely meet specific site conditions, security requirements, and aesthetic preferences.

- Tailored Dimensions: We can produce chain link fencing wire with custom heights, roll lengths, wire gauges, and mesh opening sizes to fit unique site layouts and security specifications, from small enclosures to vast perimeter defenses.

- Color Matching: For powder-coated options, we offer a broad spectrum of RAL colors, allowing seamless integration with corporate branding or environmental aesthetics, crucial for architectural and public-facing projects.

- Integrated Security Features: Custom solutions can include provisions for integrating barbed wire, razor wire, anti-climb spikes, and various access control systems (e.g., gates, turnstiles) directly into the fence design.

- Specialized Coatings: Beyond standard HDG and powder coatings, we can discuss specific protective layers for extreme chemical exposure, high abrasion environments, or specialized aesthetic finishes.

- Engineering Support: Our team provides technical drawings, stress analysis, and installation guidance to ensure the customized solution performs optimally and meets all structural and safety regulations.

This flexibility ensures that even the most complex or demanding projects can benefit from our high-quality chain link mesh fence products, delivered with precision and expertise.

Real-World Application Case Studies

Our commitment to quality and tailored solutions is best demonstrated through successful project implementations. Here are examples of how our Powder Coated / Hot Dipped Galvanized Chain Link Fence Mesh has provided reliable security and demarcation for our diverse clientele.

Case Study 1: Perimeter Security for a Major Petrochemical Complex

A leading petrochemical facility required a robust and highly corrosion-resistant perimeter fence spanning 15 kilometers in a coastal industrial zone. The environment presented significant challenges due to saline air and chemical emissions. We supplied heavy-gauge (4.0mm wire) Hot Dipped Galvanized chain link fencing wire with a zinc coating exceeding 240 g/m², meeting ASTM A392 Class 2 specifications. The fence was installed with an integrated razor wire topping. After five years, the client reported no signs of corrosion, maintaining full structural integrity, surpassing their previous fencing solution which required frequent maintenance.

Case Study 2: Public Utility Substation Enclosure with Aesthetic Integration

For a series of urban electrical substations, a public utility company needed secure enclosures that were both highly protective and visually appealing to blend into suburban landscapes. We provided Powder Coated (RAL 6005 Green) chain link mesh fence, applying a durable polyester powder over a pre-galvanized wire base. The mesh size was 50x50mm with a 3.5mm coated wire diameter. The project included custom-fabricated swing gates. Customer feedback highlighted the ease of installation, the attractive finish, and the excellent long-term performance, with minimal fading or peeling observed over seven years.

Case Study 3: Agricultural Property Demarcation in Arid Region

A large agricultural enterprise in an arid region required extensive perimeter fencing for land demarcation and livestock control. The primary concern was durability against extreme temperatures and minimal rainfall. Our solution involved supplying high-tensile 3.0mm wire Hot Dipped Galvanized chain link fencing wire in 50m rolls, which simplified transport and installation across vast distances. The robust galvanization ensured protection against the elements, and the tight mesh maintained animal control effectively. The client praised the product's resilience and ease of installation for their large-scale project.

Commitment to Trustworthiness: FAQ, Lead Time & Warranty

Building long-term partnerships in the B2B sector relies on clear communication, transparent processes, and unwavering support. We are dedicated to providing comprehensive information regarding our products and services.

Frequently Asked Questions (FAQ)

-

Q: What is the typical lead time for a wholesale order of chain link fencing wire?

A: Standard orders for our Powder Coated / Hot Dipped Galvanized Chain Link Fence Mesh typically have a lead time of 2-4 weeks, depending on order volume and specific customization requirements. Expedited options may be available upon request. We maintain robust inventory for common specifications to support urgent needs. -

Q: What warranty do you offer on your chain link products?

A: We offer a limited warranty covering defects in materials and workmanship for up to 10-15 years for our Hot Dipped Galvanized products and 5-10 years for our Powder Coated products, contingent on environmental conditions and proper installation. Full warranty details are provided with each quotation. -

Q: How do your products meet international quality standards?

A: Our manufacturing processes are ISO 9001 certified. Our chain link fencing wire adheres to relevant ASTM standards (e.g., ASTM A392 for galvanized coatings, ASTM A853 for steel wire) and European EN standards (e.g., EN 10244-2). We provide material test reports and certification documents for all shipments. -

Q: Can you assist with logistics and international shipping?

A: Yes, we have extensive experience in global logistics and can arrange for efficient and reliable shipping to various international destinations. Our team handles all necessary documentation and customs procedures to ensure a smooth delivery process.

Lead Time & Fulfillment Details

Our streamlined order fulfillment process is designed for efficiency and transparency. Upon order confirmation, clients receive a detailed production schedule. For standard products, typical lead times range from 14 to 28 calendar days. Custom orders or large volumes may extend this period, but precise timelines are always communicated upfront. We utilize advanced inventory management systems to ensure raw material availability and minimize production delays, facilitating reliable wholesale chain link fence supply.

Warranty Commitments & Customer Support

We stand behind the quality and performance of our products with robust warranty provisions. Our dedicated after-sales support team is available to address any technical queries, installation challenges, or warranty claims. Clients can reach us via phone, email, or our dedicated support portal for prompt assistance, ensuring peace of mind throughout the product's lifespan. Our long-standing relationships with global partners underscore our commitment to reliable service and customer satisfaction.

Conclusion

In an evolving industrial landscape, the demand for reliable, durable, and cost-effective perimeter security remains constant. Our Powder Coated / Hot Dipped Galvanized Chain Link Fence Mesh represents the pinnacle of engineering excellence in chain link fencing wire, offering superior corrosion resistance, high tensile strength, and exceptional longevity. By adhering to rigorous manufacturing standards, offering extensive customization, and backing our products with comprehensive support and warranties, we provide B2B clients with solutions that not only meet but exceed performance expectations. We invite you to partner with us to secure your assets and operations with the highest quality fencing available.

References

- ASTM International. "A392/A392M-07(2020) Standard Specification for Zinc-Coated Steel Chain-Link Fence Fabric." ASTM International, West Conshohocken, PA, 2020.

- European Committee for Standardization. "EN 10244-2: Steel wire and wire products - Non-ferrous metallic coatings on steel wire - Part 2: Zinc or zinc alloy coatings." CEN, Brussels, 2009.

- International Organization for Standardization. "ISO 9001:2015 - Quality management systems - Requirements." ISO, Geneva, 2015.

- The Powder Coating Institute. "Powder Coating: The Complete Finisher's Handbook." PCI, 2016.

- American Architectural Manufacturers Association. "AAMA 2603, 2604, 2605 Voluntary Specification for Performance Requirements for Organic Coatings on Aluminum Extrusions and Panels." AAMA, 2022.

-

Fancy Chain Link Fence – Durable, Stylish, and Sustainable Fencing Solutions

NewsNov.24,2025

-

Comprehensive Guide to Chain Fence Link Sets: Benefits, Applications, and Trends

NewsNov.23,2025

-

Durable and Cost-Effective 2mm Chain Link Fence for Global Applications

NewsNov.22,2025

-

Durable & Cost-Effective Chain Link Metal Fence for Diverse Global Needs

NewsNov.22,2025

-

Comprehensive Guide to Lawn Chain Link Fence: Durability, Applications, & Innovations

NewsNov.21,2025

-

Powder Coated Double Wire Mesh Fence - Anping Shengxin

NewsNov.21,2025