Oct . 14, 2025 09:20 Back to list

Galvanized Grape Vineyard Post Metal Pole Trellis Post-HDG

If you walk a vineyard after harvest, you notice something the brochures don’t mention: the trellis is the quiet workhorse. Without good posts, wire sag creeps in, rows wander, and yields waver. That’s why growers keep asking me about the Galvanized Grape Vineyard Post Metal Pole Vineyard Trellis Post. It’s a mouthful—sure—but the hardware matters.

What’s changing in vineyard trellising

Two trends stand out. First, higher wire tensions for mechanization; second, longer service life expectations (15–30 years). In fact, many customers say they’re shifting from timber to galvanized steel for consistency and labor savings. Hot-dip galvanizing with substantial zinc weight is driving this shift, especially in coastal or frost-prone sites where corrosion and impact loads collide.

Core specifications

Manufactured in North of Houzhuang Village, Anping County, Hengshui City, Hebei Province, China—an area that’s basically the heartland of wire and post fabrication.

| Parameter | Options / Values (≈ real-world use may vary) |

|---|---|

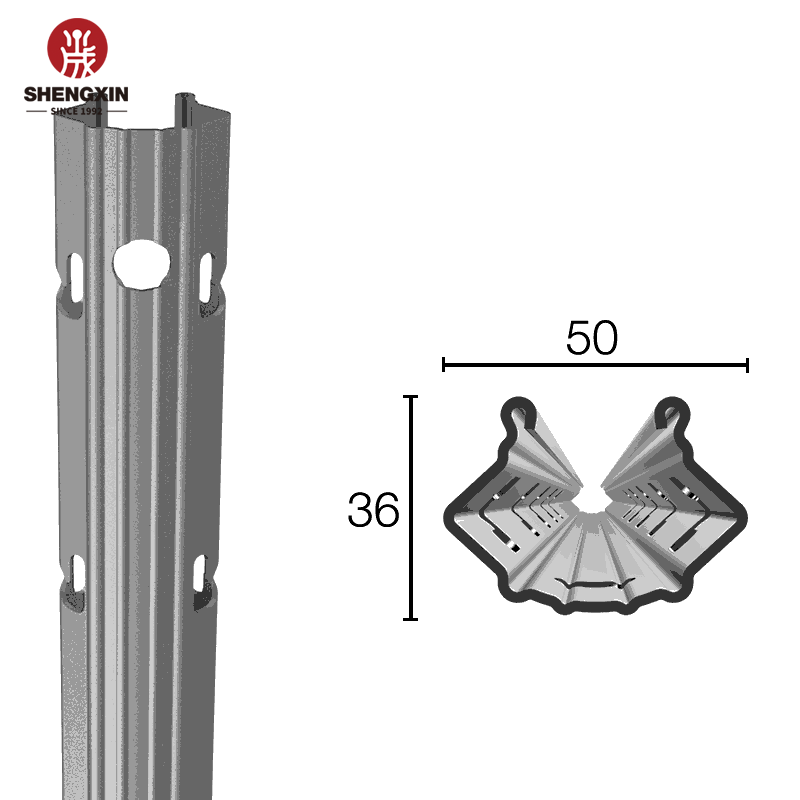

| Section size | 50×30 mm, 50×34 mm, 60×40 mm |

| Wall thickness | 1.5 mm, 2.0 mm, 2.5 mm |

| Heights | 1500, 1800, 2200, 2400, 2800 mm (others on request) |

| Finish | Hot-dip galvanized (40–275 g/m² ≈ 5.6–38.5 µm) or Electro-galvanized |

| Steel grade | Typically Q235/Q345 or equivalent mild structural steel |

| Slots/Holes | Pre-punched catch slots for catch wires; custom patterns available |

Manufacturing and testing (the practical bits)

- Materials: coil steel slit and roll-formed; edges closed for strength.

- Methods: roll forming, slot punching, deburring; hot-dip galvanizing per EN ISO 1461/ASTM A123 or electro-zinc per ASTM B633 (application-dependent).

- Coating control: target 40–275 g/m² zinc; adhesion and thickness checks with magnetic gauges.

- Mechanical checks: bend/torsion tests, wire tension simulation up to ≈10–15 kN per row segment (site-specific).

- Corrosion screening: neutral salt spray per ASTM B117 (typical 240–720 h indicative, not life prediction).

- Service life: ≈15–30 years in C2–C3 atmospheres; shorter in C4 unless zinc mass is at the higher end and maintenance is regular (per ISO 9223 guidance).

Where it’s used

Grapes (table and wine), kiwifruit, berries, and even hop yards. I’ve seen these posts double as supports for hail netting and windbreak meshes—surprisingly sturdy when you upsize to 60×40×2.5 mm.

Vendor comparison

| Vendor type | Coating & steel | Lead time | Notes |

|---|---|---|---|

| Anping-based OEM | HDG 180–275 g/m²; Q235/Q345 | ≈ 15–30 days | Stable slots, better QA, ISO 9001 common |

| Overseas trading house | Electro-zinc or light HDG (≈40–100 g/m²) | ≈ 30–45 days | Lower cost; verify coating certs |

| Local fabricator | Varies; sometimes pre-galv sheet | ≈ 7–20 days | Fast service; check slot accuracy |

Advantages and customization

- Rigid profile resists wind and machine impact; less breakage than timber in my experience.

- Higher zinc mass options for coastal blocks; to be honest, this pays off after year five.

- Custom height, slot spacing, and end-post bracing kits on request.

- Certifications: typical ISO 9001; third-party inspection (SGS/BV) available.

Growers report quicker installs—“about 1.2 km/day with a two-person crew,” one manager told me—and fewer mid-season wire resets. It seems that heavier coatings reduce red rust bleeding under bird nets, which is a small but nice win.

Real-world case, briefly

A coastal Pinot block upgraded to Galvanized Grape Vineyard Post Metal Pole Vineyard Trellis Post at 60×40×2.5 mm, HDG ≈ 275 g/m². After two winters, inspections showed negligible coating loss, and breakage dropped ≈ 15% versus old timber. Not a lab trial—just pragmatic field notes.

Galvanized Grape Vineyard Post Metal Pole Vineyard Trellis Post isn’t flashy. But if you want straighter rows, dependable wire height, and longer intervals between maintenance rounds, it’s the sort of quiet upgrade that keeps paying you back.

Authoritative references

- ASTM A123/A123M: Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

- ASTM B633: Electrodeposited Coatings of Zinc on Iron and Steel.

- ISO 9223: Corrosion of metals and alloys — Corrosivity of atmospheres.

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus.

- EN ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles.

-

Durable and Cost-Effective 2mm Chain Link Fence for Global Applications

NewsNov.22,2025

-

Durable & Cost-Effective Chain Link Metal Fence for Diverse Global Needs

NewsNov.22,2025

-

Comprehensive Guide to Lawn Chain Link Fence: Durability, Applications, & Innovations

NewsNov.21,2025

-

Powder Coated Double Wire Mesh Fence - Anping Shengxin

NewsNov.21,2025

-

Chain Link Fence System — Durable, Versatile, and Cost-Effective Fencing Solutions Worldwide

NewsNov.20,2025

-

Durable and Stylish Black Chain Link Fence Gate Solutions for Every Need

NewsNov.19,2025