Oct . 08, 2025 22:35 Back to list

Galvanized Grape Vineyard Post Metal Pole Trellis Post—Why?

Field Notes on a Workhorse: Galvanized Grape Vineyard Post Metal Pole Vineyard Trellis Post

If you spend any time around growers, you hear the same refrain: trellis integrity is crop insurance. And, to be honest, that’s why I’m bullish on these posts from Anping, Hebei—the global metalwork hub tucked up in North of Houzhuang Village, Anping County, Hengshui City, Hebei Province, China. They’re not flashy, but they’re engineered for the long haul and the daily grind of vineyard life.

Quick Industry Snapshot

Mechanized harvesting, heavier canopies, and climate volatility are pushing posts harder than ever. The trend? Thicker steel, higher zinc, and smarter profiles that resist buckling. Many customers say Z275 hot-dip or equivalent is the sweet spot for lifecycle cost—surprisingly, it often beats cheaper thin-wall imports when you count replacements.

Core Specs (field-proven)

| Parameter | Options / Data | Notes |

|---|---|---|

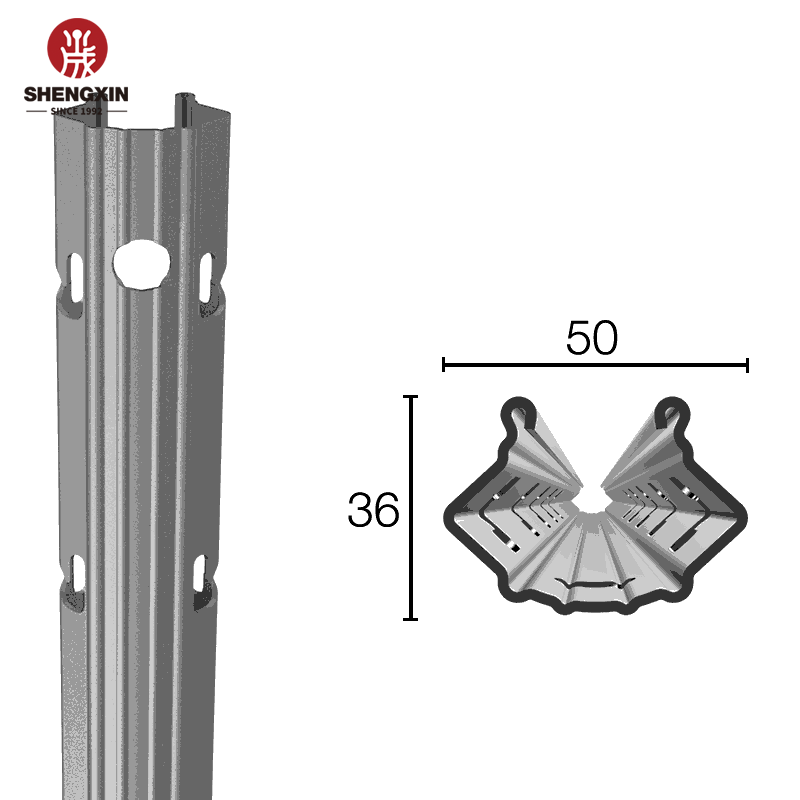

| Section size | 50×30mm, 50×34mm, 60×40mm | Roll-formed profile, anti-twist ribs optional |

| Thickness | 1.5mm, 2.0mm, 2.5mm | Pick 2.0–2.5mm for mechanical harvesting |

| Height | 1500, 1800, 2200, 2400, 2800mm (others on request) | Slope blocks often run 2400–2800mm |

| Finish | Hot-dip galvanized (≈40–275 g/m²); Electric galvanized | Real-world durability: HDG > EG |

| Material | DX51D/S250GD mild steel (typical) | Balanced ductility and yield strength |

Process Flow & Testing

- Material: galvanized coil steel (EN 10346 grade), traceable heat lots.

- Forming: roll-form + slot punching; deburr to protect wires.

- Galvanizing: HDG per ISO 1461/ASTM A123 or EG per ASTM A653; passivation.

- QC: zinc mass test (magnetic gauge, ISO 2178), straightness, pull-out and bend tests.

- Corrosion: ASTM B117 salt-spray screening; typical Z275 shows 240–480h to red rust on cut edges; main faces last longer.

- Service life: ≈15–25 years inland; ≈8–15 years coastal (wind, salt, soil pH will shift this).

Where They Shine

Primary vineyards (table and wine grapes), high-tension cordon systems, kiwifruit and berry trellises, and even wind-prone blocks. I guess the biggest win is reduced mid-season leaning and fewer cracked slots when harvesters hum through at 3 a.m.

Why growers pick these

- Stiffness-to-weight: the 60×40×2.5mm profile feels rock solid.

- Consistent slot geometry: fast wireing, less glove time.

- Coating range: from budget EG to Z275 HDG for aggressive sites.

Vendor comparison (indicative)

| Vendor | Coating | Thickness range | Lead time | Certs |

|---|---|---|---|---|

| Galvanized Grape Vineyard Post Metal Pole Vineyard Trellis Post (Anping) | EG / HDG up to ≈Z275 | 1.5–2.5mm | ≈15–30 days | ISO 9001 (factory) |

| EU Trellis Brand A | Pre-galv Z200–Z275 | 1.6–2.2mm | ≈4–6 weeks | CE marking (where applicable) |

| US Importer B | EG Z100–Z180 | 1.4–2.0mm | Stock/seasonal | Factory ISO (varies) |

Customization & Options

- Slot patterns: hook, Omega, and anti-slip keyholes; spacing tailored to canopy plan.

- End posts with anchor plates; drive-point tips for rocky soils.

- Brand embossing, batch QR, palletization for export audits.

Case notes from the field

- Marlborough, NZ: switching to Galvanized Grape Vineyard Post Metal Pole Vineyard Trellis Post in 60×40×2.5mm cut broken-post rates by ≈40% during harvest, estate manager reports.

- La Mancha, ES: Z275 HDG posts held line tension after two hailstorms; minimal slot deformation, according to the grower co-op.

Bottom line: the Galvanized Grape Vineyard Post Metal Pole Vineyard Trellis Post balances cost and longevity. Not perfect for every terroir—coastal blocks may still want heavier zinc or sacrificial anodes—but for most vineyards, it’s a very pragmatic upgrade.

References

-

Fancy Chain Link Fence – Durable, Stylish, and Sustainable Fencing Solutions

NewsNov.24,2025

-

Comprehensive Guide to Chain Fence Link Sets: Benefits, Applications, and Trends

NewsNov.23,2025

-

Durable and Cost-Effective 2mm Chain Link Fence for Global Applications

NewsNov.22,2025

-

Durable & Cost-Effective Chain Link Metal Fence for Diverse Global Needs

NewsNov.22,2025

-

Comprehensive Guide to Lawn Chain Link Fence: Durability, Applications, & Innovations

NewsNov.21,2025

-

Powder Coated Double Wire Mesh Fence - Anping Shengxin

NewsNov.21,2025