Nov . 17, 2024 10:47 Back to list

Metal Brackets for Durable Panel Fence Manufacturing Solutions

Metal Bracket for Panel Fence A Comprehensive Guide for Manufacturers

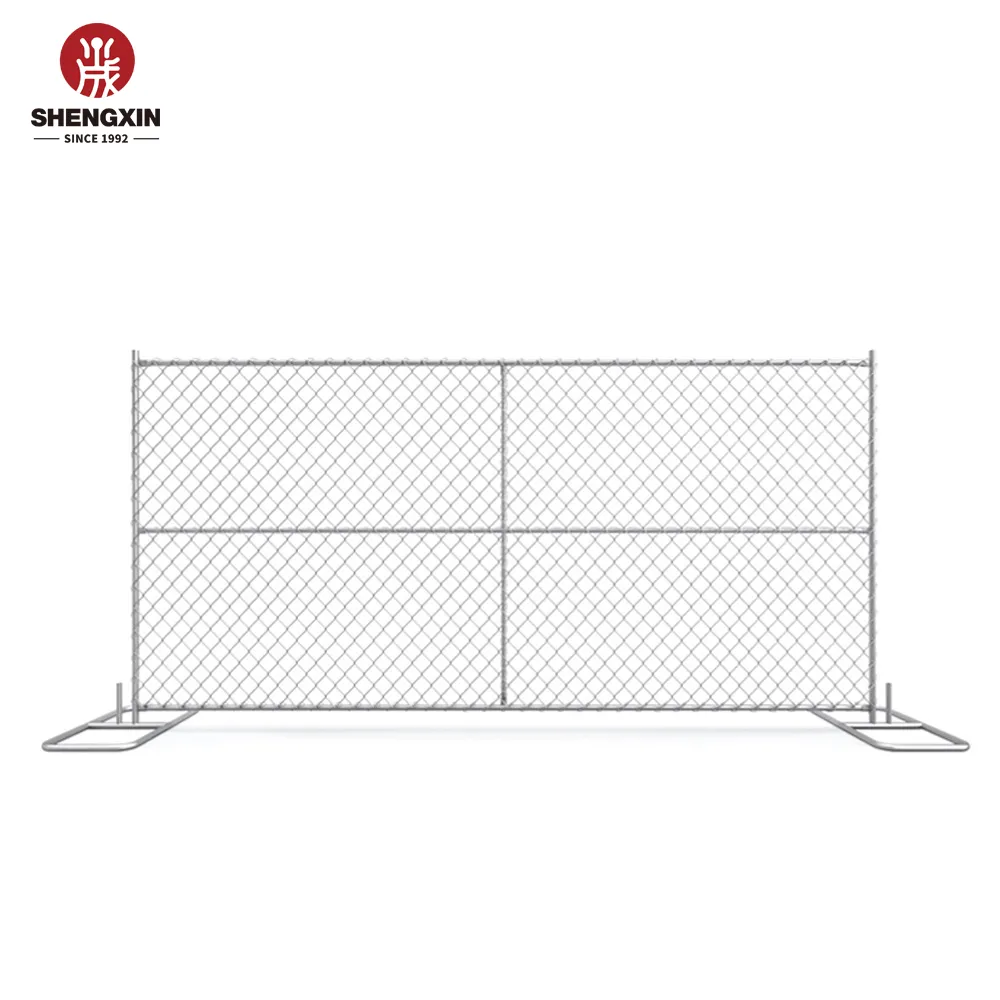

In the world of fencing, metal brackets are essential components that provide stability and support to panel fences. Understanding the significance of these brackets and their manufacturing process is crucial for manufacturers aiming to deliver high-quality fencing solutions.

Metal brackets for panel fences serve multiple purposes, including securing fence panels to support posts, enabling ease of installation, and enhancing the longevity of the fencing system. They are particularly favored in residential and commercial applications due to their durability and resistance to weather elements.

Design and Materials

When it comes to manufacturing metal brackets, the choice of materials is paramount. The most commonly used materials include galvanized steel, stainless steel, and powder-coated metals. Galvanized steel is popular for its corrosion resistance and strength, making it ideal for outdoor use. Stainless steel, while more expensive, offers superior corrosion resistance, particularly in coastal areas where salt exposure can lead to rapid degradation of metal components. Powder-coated metals provide an aesthetic finish and additional protection against rust and wear.

The design of the brackets must also be addressed. Brackets come in various shapes and sizes depending on the fencing system's specific requirements. Common designs include L-brackets, T-brackets, and corner brackets, each serving unique purposes in panel alignment and stability. A well-designed bracket should facilitate easy installation while guaranteeing the security of the fence panels.

metal bracket for panel fence manufacturer

Manufacturing Process

The manufacturing process for metal brackets typically involves several steps cutting, bending, welding, and finishing. Initially, flat sheets of metal are cut to the required dimensions using precision tools. This is followed by bending the metal into the desired shape. For brackets that require added strength, welding may be employed to join multiple pieces together.

After shaping, the brackets go through a finishing process, which may include galvanization, powder coating, or painting to enhance durability and aesthetic appeal. Quality control is vital throughout the manufacturing process to ensure that each bracket meets industry standards and performs as intended.

Market Demand and Trends

The market for panel fence metal brackets is growing, driven by increasing demand for durable fencing solutions in both residential and commercial sectors. Manufacturers must stay aware of industry trends, such as the shift toward sustainable materials and eco-friendly manufacturing practices. By incorporating recycled materials and minimizing waste, manufacturers can appeal to environmentally-conscious consumers.

In conclusion, metal brackets are critical components in the construction of panel fences. As manufacturers strive to produce high-quality brackets, focusing on material selection, innovative designs, and efficient manufacturing processes will be key to meeting market demand and ensuring customer satisfaction. With the right approach, manufacturers can establish themselves as leaders in the fencing industry.

-

Premium ODM 7' Security Fence - High-Security & Durable

NewsAug.01,2025

-

Powder Coated Double Wire Mesh Fence for Germany Market - Anping County Shengxin Metal Products Co., Ltd.

NewsJul.31,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd.|Durable, Corrosion-Resistant, Customizable

NewsJul.31,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd | Durable Corrosion Resistant Fencing

NewsJul.31,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd | Durability, Corrosion Resistance

NewsJul.31,2025

-

Privacy Chain Link Fence Slats | Durable Solutions

NewsJul.31,2025