Sep . 23, 2025 01:50 Back to list

ODM 7' Security Fence: 358 Anti-Climb, Galvanized Panels

The Imperative of High-Security Fencing in Modern Infrastructure

In an era of evolving security threats and stringent regulatory compliance, the demand for robust and reliable perimeter protection has never been more critical for B2B sectors. Industries ranging from petrochemical and energy to critical infrastructure and data centers require advanced solutions that deter intrusion, withstand environmental challenges, and offer long-term cost-effectiveness. This comprehensive article delves into the technical intricacies, application versatility, and strategic advantages of the odm 7' security fence, a premier solution designed to meet and exceed the most demanding security requirements.

We will explore its manufacturing precision, technical specifications, diverse application scenarios, and how it aligns with the highest standards of safety, durability, and sustainability. Understanding these facets is crucial for procurement specialists, project managers, and security professionals seeking to optimize their asset protection strategies.

Current Industry Trends in Perimeter Security

The landscape of perimeter security is continually evolving, driven by technological advancements, heightened threat perceptions, and a growing emphasis on environmental responsibility. Key trends include:

- Integration of Smart Technologies: Fencing solutions are increasingly integrated with surveillance systems, access control, and analytics for real-time threat detection and response. This elevates the fence from a passive barrier to an active component of a security ecosystem.

- Enhanced Anti-Climb and Anti-Cut Features: The proliferation of advanced cutting tools necessitates fences with smaller mesh apertures, such as the 358 anti climb fence design, which significantly impedes climbing and cutting attempts.

- Sustainability and Longevity: Demand for eco-friendly materials and coatings, like PVC/powder coated finishes on coating galvanized steel wire mesh fencing panels, is rising. These not only extend service life but also reduce environmental impact.

- Customization and Modular Design: Projects often require bespoke solutions. Manufacturers are offering highly customizable odm 7' security fence systems that adapt to diverse terrains and specific threat profiles, featuring components like 3d curved welded wire mesh fence panel for added rigidity.

- Focus on Total Cost of Ownership (TCO): Beyond initial purchase, clients prioritize fences that offer minimal maintenance, exceptional durability, and extended service life, thereby reducing long-term operational expenditures. This makes high-quality odm 7' security fence a strategic investment.

These trends underscore the importance of selecting a security fencing solution that is not only physically formidable but also technologically adaptable and economically viable over its lifecycle.

Manufacturing Process of the ECO Friendly ODM 7' Security Fence

The production of a high-quality odm 7' security fence, such as the ECO Friendly Fence PVC / Powder Coated 3D Curved Welded Wire Mesh Fence, involves a meticulous, multi-stage process designed to ensure superior strength, durability, and corrosion resistance. This process adheres to rigorous international standards, including ISO 9001 for quality management and relevant ASTM/ANSI specifications for materials and performance.

Process Flow Schematic:

- 1. Wire Rod Selection & Drawing: High-grade carbon steel wire rods (typically SAE 1006/1008) are sourced. These rods undergo cold drawing to achieve precise wire diameters (e.g., 4mm, 5mm, 6mm) with enhanced tensile strength (typically 500-700 MPa). This ensures the foundational integrity of the odm 7' security fence.

- 2. Welding & Panel Fabrication: The drawn wires are precisely welded using automated resistance welding machines to form the mesh panels. The panels incorporate 3D curves, which are pressed into the mesh to provide superior rigidity and aesthetic appeal. For "358" style panels, the mesh aperture is precisely controlled at 76.2mm x 12.7mm (3" x 0.5").

- 3. Galvanization (Corrosion Protection Base):

- Hot-Dip Galvanization: Panels are immersed in molten zinc at approximately 450°C. This creates a metallurgical bond, forming multiple layers of zinc-iron alloys and an outer layer of pure zinc, providing exceptional cathodic and barrier protection. Coating thickness typically ranges from 45-85 microns, conforming to EN ISO 1461.

- Electro-Galvanization (Optional/Alternative): A thinner, more uniform zinc coating (10-20 microns) applied via an electrolytic process, often used when a smoother surface is desired for subsequent powder coating.

- 4. Pre-treatment & Cleaning: Galvanized panels undergo a multi-stage cleaning and pre-treatment process to ensure optimal adhesion for the final coating. This includes degreasing, rinsing, iron phosphating (for powder coating), and demineralized water rinses. This step is critical for the longevity of the coating galvanized steel wire mesh fencing panels.

- 5. PVC / Powder Coating Application:

- Powder Coating: Electrostatic spray guns apply thermosetting polyester powder onto the earthed panels. The powder adheres uniformly, offering excellent UV stability and a tough, aesthetic finish (typically 80-120 microns thickness).

- PVC Coating: Panels are heated, then dipped into a fluidized bed of PVC powder, or coated via a fusion-bonded spray process. This results in a much thicker, highly impact-resistant, and flexible coating (typically 400-500 microns thickness), ideal for harsh environments.

- 6. Curing & Polymerization: Coated panels are moved into curing ovens where high temperatures (e.g., 180-220°C for powder coating) melt and cross-link the polymer particles, forming a durable, continuous protective layer.

- 7. Quality Control & Inspection: Each panel undergoes stringent quality checks, including adhesion tests (cross-hatch test per ISO 2409), coating thickness measurement, impact resistance, salt spray testing (per ASTM B117/ISO 9227 for 1000+ hours), and visual inspection for defects. This ensures compliance with all performance criteria for the odm 7' security fence.

- 8. Packaging & Dispatch: Finished panels are carefully packaged to prevent damage during transit, often with protective wraps and wooden pallets, ready for shipment by 358 anti climb fence exporters.

The service life of a properly manufactured and installed odm 7' security fence, with dual layer protection (galvanization + PVC/powder coating), can exceed 20-30 years in typical environmental conditions, significantly outperforming un-coated or single-layer protected fences.

Technical Specifications & Parameters

The effectiveness of any security fence hinges on its precise technical specifications. The ECO Friendly Fence PVC / Powder Coated 3D Curved Welded Wire Mesh Fence, designed as a robust odm 7' security fence, offers a suite of parameters engineered for optimal security and longevity.

Key Product Specifications:

| Parameter | Details / Specification | Standard Adherence |

|---|---|---|

| Product Name | ECO Friendly Fence PVC / Powder Coated 3D Curved Welded Wire Mesh Fence | Manufacturer Internal |

| Fence Height | 2.1 meters (7 feet) - Customizable | Project Specific |

| Panel Width | 2.0m, 2.5m, 3.0m - Customizable | EN 10223-7 |

| Wire Diameter | Typically 4.0mm, 5.0mm, 6.0mm (pre-coated) | ASTM A641, EN 10218-2 |

| Mesh Aperture | 50x200mm standard; 76.2x12.7mm (358 mesh) available for high security | EN 10223-7 |

| Material | Low Carbon Steel Wire (e.g., Q195/Q235 grade) | ASTM A641, EN 10223-7 |

| Surface Treatment | Hot-dip Galvanized then PVC Coated OR Hot-dip Galvanized then Powder Coated | EN ISO 1461 (Galvanization), ISO 9227 (Salt Spray), ASTM B117 |

| Coating Thickness (Powder) | Min. 80 microns, typically 100-120 microns | ISO 2808 |

| Coating Thickness (PVC) | Min. 400 microns, typically 450-500 microns | ISO 2808 |

| Tensile Strength | 500-700 MPa (post-drawing) | EN 10218-2 |

| Post Diameter | 60x60mm square, 60mm round, or 75x75mm square - various options | Manufacturer Internal |

| Service Life Expectancy | 20-30+ years with proper installation and maintenance | Accelerated Weathering Tests |

The selection of wire diameter, mesh size, and coating type directly impacts the fence's security level, rigidity, and resistance to environmental degradation. For instance, the tight mesh of a 358 anti climb fence variant prevents handholds and footholds, making it virtually impossible to scale without specialized tools, while the coating galvanized steel wire mesh fencing panels ensure superior weather resistance.

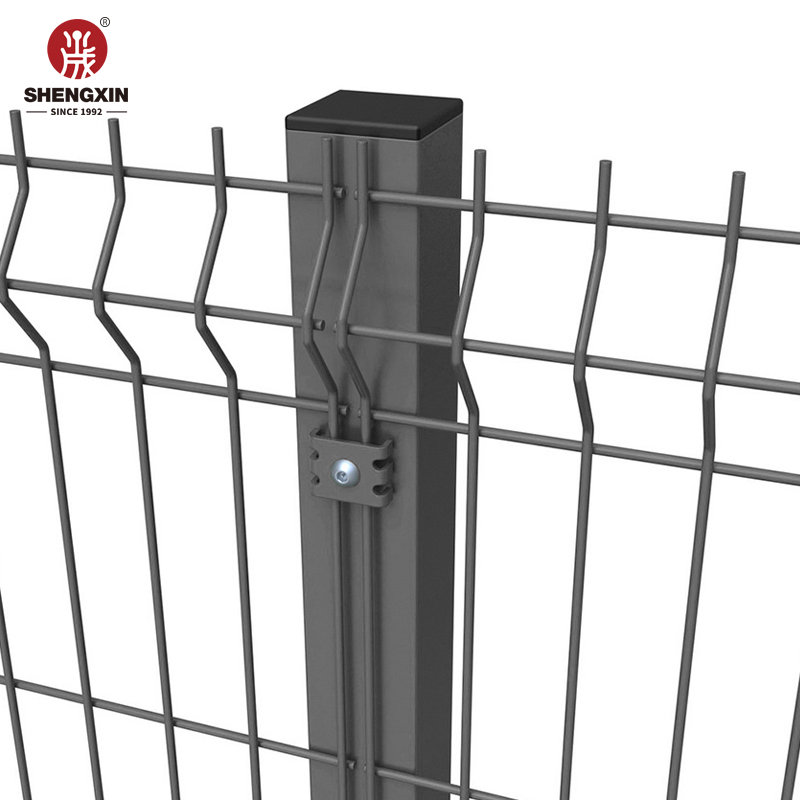

Figure 1: High-security odm 7' security fence featuring 3D curved panels.

Diverse Application Scenarios and Target Industries

The robust design and superior protection offered by the odm 7' security fence make it an ideal choice across a spectrum of demanding industries and critical infrastructure projects. Its inherent properties, such as high anti-corrosion and anti-climb capabilities, ensure reliability in harsh or high-risk environments.

- Petrochemical and Energy Sector: For oil refineries, gas storage facilities, power plants, and renewable energy sites, perimeter security is non-negotiable. The corrosion resistance of PVC/powder coated coating galvanized steel wire mesh fencing panels is crucial against chemical exposure and saline environments, ensuring long-term asset protection. The 358 anti climb fence variant is particularly favored here due to its high deterrence.

- Metallurgy and Mining: Securing valuable raw materials, processing plants, and equipment yards against theft and unauthorized access. The durability of the odm 7' security fence stands up to heavy industrial conditions.

- Water Supply & Drainage Facilities: Protecting reservoirs, pumping stations, water treatment plants, and critical pipelines from contamination and sabotage. The eco-friendly coatings also ensure no adverse impact on water quality.

- Data Centers and IT Infrastructure: High-security perimeters are essential to protect sensitive data and hardware. The anti-climb features of the odm 7' security fence provide an initial layer of defense against physical breaches.

- Transportation Hubs: Airports, seaports, railway depots, and logistics centers require secure boundaries to control access and prevent illicit activities. The 3d curved welded wire mesh fence panel design offers enhanced aesthetic integration while maintaining high security.

- Military and Government Installations: Where national security is paramount, these fences provide a formidable physical barrier against unauthorized entry.

- Commercial and Industrial Parks: Securing business assets, warehouses, and manufacturing facilities from theft and vandalism, reducing insurance costs and improving overall safety.

In these scenarios, the advantages of energy saving in manufacturing, coupled with exceptional corrosion resistance and a prolonged service life, translate directly into reduced operational costs and enhanced security posture for businesses.

Technical Advantages and Performance Metrics

The technical superiority of the odm 7' security fence stems from its carefully engineered design and advanced material science. These advantages translate into tangible benefits for critical infrastructure projects and commercial enterprises alike.

- Superior Corrosion Resistance: The dual-layer protection of hot-dip galvanization followed by PVC or powder coating provides an unparalleled defense against rust, chemical exposure, and UV degradation. This system is proven to withstand over 1000 hours of salt spray testing (ASTM B117), ensuring decades of maintenance-free operation even in harsh coastal or industrial environments.

- High Anti-Climb & Anti-Cut Capabilities: Especially with the 358 anti climb fence mesh aperture (76.2x12.7mm), it's virtually impossible to grip or cut with standard tools. This "prison mesh" design significantly deters intruders, making it ideal for high-security applications. The robust wire diameter and welding integrity further enhance resistance to forced entry.

- Enhanced Structural Rigidity: The 3d curved welded wire mesh fence panel design incorporates horizontal V-bends that dramatically increase panel strength and resistance to bending or deformation, reducing the need for additional support structures. This inherent strength reduces material fatigue over time.

- Eco-Friendly & Sustainable: Our ECO Friendly Fence utilizes PVC/powder coatings that are lead-free and comply with environmental regulations. The extended service life minimizes replacement cycles, reducing waste and contributing to lower carbon footprints over the fence's lifecycle.

- Low Maintenance Requirement: Thanks to the durable coating galvanized steel wire mesh fencing panels, periodic painting or anti-corrosion treatments are unnecessary, significantly lowering the total cost of ownership.

- Rapid Installation: The modular design of the panels and posts, combined with specialized fixing clips, allows for swift and efficient installation, minimizing project timelines and labor costs.

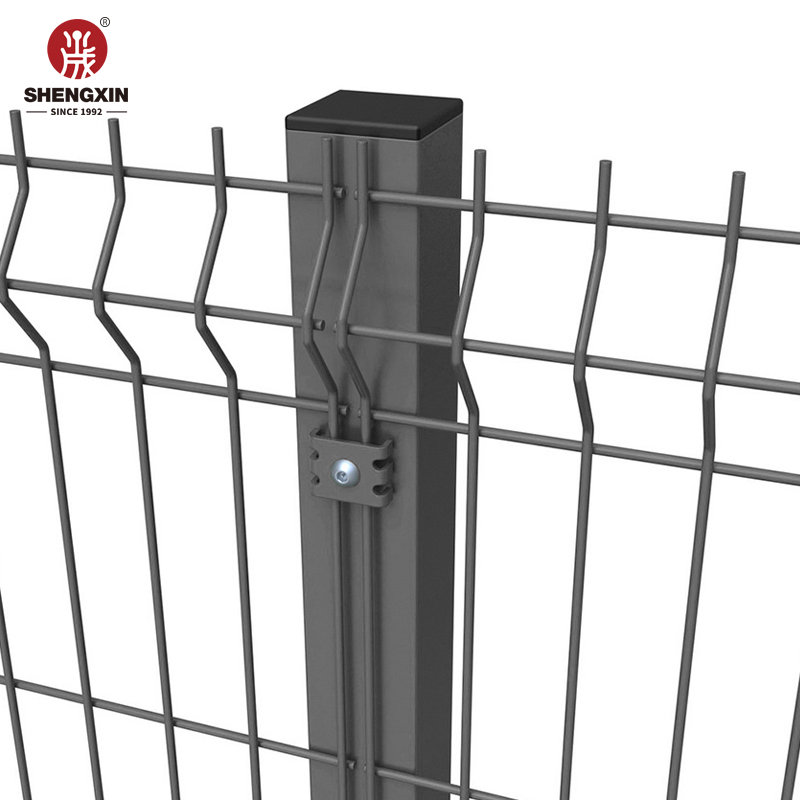

Figure 2: Detail of the secure mesh and post connection of an odm 7' security fence.

Vendor Comparison: Why Choose a Specialized 358 Anti Climb Fence Supplier

When procuring a high-security fencing solution like the odm 7' security fence, selecting the right vendor is paramount. Not all 358 anti climb fence suppliers or 358 anti climb fence manufacturers offer the same level of expertise, quality, and service. A direct comparison highlights the value of specialized providers.

Key Differentiators in Vendor Selection:

| Feature | Specialized 358 Anti Climb Fence Supplier | General Fence Manufacturer / Distributor |

|---|---|---|

| Product Quality & Standards | Adheres to strict international standards (ISO, ASTM, EN). Consistent wire diameter, weld strength, and coating thickness. Certifications readily available. High-grade raw materials. | Varies greatly. May use lower-grade materials or less precise manufacturing, leading to inconsistent quality and reduced longevity. Limited certifications. |

| Customization Capabilities | Offers comprehensive tailored solutions for fence height, panel width, mesh size, wire gauge, and specific coating types (PVC vs. Powder) to meet unique project requirements. Deep engineering expertise for complex projects. | Limited customization, typically offering standard sizes and finishes. May struggle with specialized requests or unique site conditions. |

| Technical Support & Expertise | Dedicated technical teams for design, engineering, and installation support. Can provide detailed CAD drawings, stress analyses, and on-site consultation. Expertise in 358 anti climb fence service. | Basic product information; limited engineering or design support. May lack deep understanding of complex security requirements. |

| Lead Time & Logistics | Efficient production lines and established logistics networks ensure reliable lead times and global delivery, supported by experienced 358 anti climb fence exporters. | Lead times can be unpredictable, especially for non-standard orders. Logistics may be less optimized, leading to delays. |

| Warranty & After-Sales | Comprehensive warranties (e.g., 10-20 years on coating) backed by established quality control. Responsive after-sales support for any issues. | Shorter or less clear warranties. After-sales support may be limited or outsourced. |

| Pricing & Value | While initial 358 anti climb fence quotes might seem higher, the long-term value from superior durability, lower maintenance, and guaranteed performance results in a lower Total Cost of Ownership (TCO). | Lower upfront cost but often leads to higher TCO due to premature failure, increased maintenance, or inadequate security. |

Partnering with experienced 358 anti climb fence factories and 358 anti climb fence suppliers like us ensures access to cutting-edge manufacturing, engineering excellence, and reliable project execution for your odm 7' security fence needs.

Customized Solutions for Unique Security Challenges

Every security project presents a unique set of challenges, from undulating terrain to specific threat assessments. Recognizing this, leading manufacturers of the odm 7' security fence offer comprehensive customized solutions to ensure optimal performance and seamless integration.

- Tailored Dimensions: Beyond the standard 7-foot height, fences can be custom-fabricated to heights up to 12 feet or more, with varying panel widths to minimize cutting and waste on-site.

- Mesh Configurations: While the 358 anti-climb mesh is standard for high-security, other mesh apertures can be customized for specific visual permeability or aesthetic requirements.

- Coating Options: Choice between robust PVC coating for extreme corrosive environments or high-adhesion powder coating for superior UV stability and color customization (RAL colors).

- Post and Fixings: Various post types (square, round, rectangular hollow section) and anti-tamper fixing mechanisms are available to suit ground conditions and security levels.

- Integrated Security Features: Seamless integration with razor wire, barbed wire, electric fencing, CCTV mounting brackets, and access control systems for a multi-layered security approach.

- Gate Systems: Matching swing gates, sliding gates, and cantilever gates, all fabricated with the same high-security panels and coating, ensuring consistent aesthetics and protection.

Our expert engineers engage in detailed consultations to understand project specific needs, providing CAD designs and structural analyses to ensure that the customized odm 7' security fence solution perfectly aligns with security objectives and budget constraints.

Application Case Studies & Customer Success

The proven reliability of our ECO Friendly Fence PVC / Powder Coated 3D Curved Welded Wire Mesh Fence is best demonstrated through real-world applications and positive customer feedback. As a leading 358 anti climb fence supplier and 358 anti climb fence manufacturer, we have deployed advanced fencing solutions across diverse high-stakes environments.

- Case Study 1: Major European Data Center (2019-2021)

Challenge: Secure a new 15-acre data center facility requiring Level 3 perimeter protection against sophisticated intrusion attempts, with a focus on long-term, low-maintenance operation.

Solution: Installation of 4.5 km of odm 7' security fence, specifically 358 anti-climb mesh with hot-dip galvanized and PVC fusion-bonded coating. Integrated with CCTV posts and fiber optic intrusion detection systems.

Outcome: Zero perimeter breaches reported since installation. Customer feedback highlighted exceptional durability against severe weather conditions and significant cost savings on maintenance compared to previous installations. The tight mesh prevented even small animals from entering. - Case Study 2: Coastal Petrochemical Plant, Middle East (2020-2022)

Challenge: Protect critical processing units from unauthorized access and the corrosive effects of a highly saline, humid environment, requiring a fence with superior anti-corrosion properties and a 20+ year service life.

Solution: Custom-designed odm 7' security fence panels, featuring enhanced hot-dip galvanization (min. 85 microns) followed by a 500-micron thick PVC coating. Specialized anti-climb tops were integrated.

Outcome: Independent inspection after 2 years confirmed zero signs of corrosion or degradation. The client reported enhanced peace of mind and satisfaction with the fence's performance under extreme conditions, citing its "unmatched resilience." This project exemplifies the value offered by reputable 358 anti climb fence service providers. - Case Study 3: International Airport Perimeter Upgrade, Asia (2021-2023)

Challenge: Upgrade existing perimeter fencing to meet international aviation security standards, requiring a highly secure, visually unobtrusive solution that could be rapidly deployed without disrupting airport operations.

Solution: Deployment of a 7-foot tall odm 7' security fence using 3d curved welded wire mesh fence panel design for aesthetic appeal and increased rigidity, with a dark green powder coating for blending into the landscape. Quick-install post systems were utilized.

Outcome: The project was completed ahead of schedule. Security audits confirmed the fence exceeded the required standards for intrusion deterrence. The airport authority praised the discreet appearance and the robustness of the system.

Ensuring Trustworthiness: FAQs, Lead Times, Warranty & Support

Building trust with our B2B partners is foundational. We ensure transparency in our processes, commitments, and support for every odm 7' security fence project.

Frequently Asked Questions (FAQ):

Q1: What is the typical lead time for an odm 7' security fence order?

A1: Standard orders typically have a lead time of 3-4 weeks from order confirmation. Customized solutions or very large projects may require 5-8 weeks. We provide a precise timeline with every 358 anti climb fence quotes.

Q2: What warranty is provided for the coating galvanized steel wire mesh fencing panels?

A2: We offer a comprehensive 10-year warranty against manufacturing defects and coating degradation (e.g., severe peeling, cracking, or premature rust-through) under normal environmental conditions for both PVC and powder-coated finishes. This can be extended up to 20 years for specific high-performance coatings or project types, as agreed.

Q3: Can the fence be installed on uneven terrain?

A3: Yes, the modular design and post installation methods allow for adaptation to undulating terrains. Our technical team can provide detailed guidance and custom panel designs to accommodate slopes and curves effectively, ensuring the integrity of the odm 7' security fence remains uncompromised.

Q4: Are your fences compliant with international security standards?

A4: Absolutely. Our products adhere to or exceed relevant international standards such as ISO 9001 (Quality Management), EN 10223-7 (Welded Steel Wire Mesh Fences), ASTM A641 (Zinc-Coated Carbon Steel Wire), and ISO 9227/ASTM B117 (Salt Spray Testing). We are committed to maintaining the highest quality for our B2B clients, as expected from a leading 358 anti climb fence manufacturers.

Lead Time & Fulfillment:

Our streamlined manufacturing processes and robust supply chain enable us to manage project timelines efficiently. For urgent requirements, we offer expedited production options. All orders are meticulously inspected and packaged to prevent damage during transit, ensuring on-time and intact delivery through our reliable network of 358 anti climb fence exporters.

Comprehensive Customer Support:

From initial consultation to post-installation support, our dedicated customer service team and technical experts are available to assist. We provide detailed installation guides, technical drawings, and troubleshooting support. Our commitment extends throughout the entire lifecycle of your odm 7' security fence, ensuring long-term satisfaction and optimal security performance.

Conclusion: A Strategic Investment in Perimeter Security

The selection of a perimeter security system is a critical decision for any B2B entity. The ECO Friendly Fence PVC / Powder Coated 3D Curved Welded Wire Mesh Fence, as a leading odm 7' security fence solution, offers an unmatched combination of technical superiority, environmental responsibility, and long-term cost-effectiveness. Its robust construction, advanced anti-corrosion treatments, and formidable anti-climb design make it an indispensable asset for protecting critical infrastructure and valuable assets across diverse industries.

By understanding the detailed manufacturing process, comprehensive technical specifications, and broad application potential, businesses can make informed decisions that safeguard their operations, meet regulatory requirements, and ensure peace of mind for decades to come. Partnering with a specialized and reputable 358 anti climb fence supplier guarantees not just a product, but a complete, reliable, and sustainable security solution.

References:

- International Organization for Standardization (ISO). (n.d.). ISO 9001: Quality management systems – Requirements. Retrieved from www.iso.org

- ASTM International. (n.d.). ASTM A641/A641M-09: Standard Specification for Zinc–Coated (Galvanized) Carbon Steel Wire. Retrieved from www.astm.org

- European Committee for Standardization (CEN). (n.d.). EN 10223-7: Steel wire and wire products for fencing and netting - Part 7: Steel welded panels for fencing. Retrieved from standards.cencenelec.eu

- NACE International (now AMPP). (n.d.). Corrosion Engineering Handbook. Retrieved from www.ampp.org

- The Galvanizers Association. (n.d.). Hot Dip Galvanizing: A Guide to Best Practice. Retrieved from www.galvanizing.org.uk

-

3D Welded Wire Mesh Metal Fence Panels with Peach Post Rigid

NewsNov.17,2025

-

odm 7' security fence: Anti-Climb, Galvanized, 3D Panels

NewsNov.17,2025

-

4.7cm Hard PVC Privacy Strip+100 Clips, Chain-Link Fence, UV

NewsNov.17,2025

-

Powder-Coated Square Fence Posts – Decorative, Removable

NewsNov.17,2025

-

Chain Link Fence Temporary Fence - Durable, Secure, Fast

NewsNov.17,2025

-

Bike Storage Rack 1-6 Bicycle Floor Parking Stand, Durable

NewsNov.11,2025

Sep . 08, 2025 16:39 Back to list

ODM 7' Security Fence: 358 Anti-Climb, Galvanized Panels

The Imperative of High-Security Fencing in Modern Infrastructure

In an era of evolving security threats and stringent regulatory compliance, the demand for robust and reliable perimeter protection has never been more critical for B2B sectors. Industries ranging from petrochemical and energy to critical infrastructure and data centers require advanced solutions that deter intrusion, withstand environmental challenges, and offer long-term cost-effectiveness. This comprehensive article delves into the technical intricacies, application versatility, and strategic advantages of the odm 7' security fence, a premier solution designed to meet and exceed the most demanding security requirements.

We will explore its manufacturing precision, technical specifications, diverse application scenarios, and how it aligns with the highest standards of safety, durability, and sustainability. Understanding these facets is crucial for procurement specialists, project managers, and security professionals seeking to optimize their asset protection strategies.

Current Industry Trends in Perimeter Security

The landscape of perimeter security is continually evolving, driven by technological advancements, heightened threat perceptions, and a growing emphasis on environmental responsibility. Key trends include:

- Integration of Smart Technologies: Fencing solutions are increasingly integrated with surveillance systems, access control, and analytics for real-time threat detection and response. This elevates the fence from a passive barrier to an active component of a security ecosystem.

- Enhanced Anti-Climb and Anti-Cut Features: The proliferation of advanced cutting tools necessitates fences with smaller mesh apertures, such as the 358 anti climb fence design, which significantly impedes climbing and cutting attempts.

- Sustainability and Longevity: Demand for eco-friendly materials and coatings, like PVC/powder coated finishes on coating galvanized steel wire mesh fencing panels, is rising. These not only extend service life but also reduce environmental impact.

- Customization and Modular Design: Projects often require bespoke solutions. Manufacturers are offering highly customizable odm 7' security fence systems that adapt to diverse terrains and specific threat profiles, featuring components like 3d curved welded wire mesh fence panel for added rigidity.

- Focus on Total Cost of Ownership (TCO): Beyond initial purchase, clients prioritize fences that offer minimal maintenance, exceptional durability, and extended service life, thereby reducing long-term operational expenditures. This makes high-quality odm 7' security fence a strategic investment.

These trends underscore the importance of selecting a security fencing solution that is not only physically formidable but also technologically adaptable and economically viable over its lifecycle.

Manufacturing Process of the ECO Friendly ODM 7' Security Fence

The production of a high-quality odm 7' security fence, such as the ECO Friendly Fence PVC / Powder Coated 3D Curved Welded Wire Mesh Fence, involves a meticulous, multi-stage process designed to ensure superior strength, durability, and corrosion resistance. This process adheres to rigorous international standards, including ISO 9001 for quality management and relevant ASTM/ANSI specifications for materials and performance.

Process Flow Schematic:

- 1. Wire Rod Selection & Drawing: High-grade carbon steel wire rods (typically SAE 1006/1008) are sourced. These rods undergo cold drawing to achieve precise wire diameters (e.g., 4mm, 5mm, 6mm) with enhanced tensile strength (typically 500-700 MPa). This ensures the foundational integrity of the odm 7' security fence.

- 2. Welding & Panel Fabrication: The drawn wires are precisely welded using automated resistance welding machines to form the mesh panels. The panels incorporate 3D curves, which are pressed into the mesh to provide superior rigidity and aesthetic appeal. For "358" style panels, the mesh aperture is precisely controlled at 76.2mm x 12.7mm (3" x 0.5").

- 3. Galvanization (Corrosion Protection Base):

- Hot-Dip Galvanization: Panels are immersed in molten zinc at approximately 450°C. This creates a metallurgical bond, forming multiple layers of zinc-iron alloys and an outer layer of pure zinc, providing exceptional cathodic and barrier protection. Coating thickness typically ranges from 45-85 microns, conforming to EN ISO 1461.

- Electro-Galvanization (Optional/Alternative): A thinner, more uniform zinc coating (10-20 microns) applied via an electrolytic process, often used when a smoother surface is desired for subsequent powder coating.

- 4. Pre-treatment & Cleaning: Galvanized panels undergo a multi-stage cleaning and pre-treatment process to ensure optimal adhesion for the final coating. This includes degreasing, rinsing, iron phosphating (for powder coating), and demineralized water rinses. This step is critical for the longevity of the coating galvanized steel wire mesh fencing panels.

- 5. PVC / Powder Coating Application:

- Powder Coating: Electrostatic spray guns apply thermosetting polyester powder onto the earthed panels. The powder adheres uniformly, offering excellent UV stability and a tough, aesthetic finish (typically 80-120 microns thickness).

- PVC Coating: Panels are heated, then dipped into a fluidized bed of PVC powder, or coated via a fusion-bonded spray process. This results in a much thicker, highly impact-resistant, and flexible coating (typically 400-500 microns thickness), ideal for harsh environments.

- 6. Curing & Polymerization: Coated panels are moved into curing ovens where high temperatures (e.g., 180-220°C for powder coating) melt and cross-link the polymer particles, forming a durable, continuous protective layer.

- 7. Quality Control & Inspection: Each panel undergoes stringent quality checks, including adhesion tests (cross-hatch test per ISO 2409), coating thickness measurement, impact resistance, salt spray testing (per ASTM B117/ISO 9227 for 1000+ hours), and visual inspection for defects. This ensures compliance with all performance criteria for the odm 7' security fence.

- 8. Packaging & Dispatch: Finished panels are carefully packaged to prevent damage during transit, often with protective wraps and wooden pallets, ready for shipment by 358 anti climb fence exporters.

The service life of a properly manufactured and installed odm 7' security fence, with dual layer protection (galvanization + PVC/powder coating), can exceed 20-30 years in typical environmental conditions, significantly outperforming un-coated or single-layer protected fences.

Technical Specifications & Parameters

The effectiveness of any security fence hinges on its precise technical specifications. The ECO Friendly Fence PVC / Powder Coated 3D Curved Welded Wire Mesh Fence, designed as a robust odm 7' security fence, offers a suite of parameters engineered for optimal security and longevity.

Key Product Specifications:

| Parameter | Details / Specification | Standard Adherence |

|---|---|---|

| Product Name | ECO Friendly Fence PVC / Powder Coated 3D Curved Welded Wire Mesh Fence | Manufacturer Internal |

| Fence Height | 2.1 meters (7 feet) - Customizable | Project Specific |

| Panel Width | 2.0m, 2.5m, 3.0m - Customizable | EN 10223-7 |

| Wire Diameter | Typically 4.0mm, 5.0mm, 6.0mm (pre-coated) | ASTM A641, EN 10218-2 |

| Mesh Aperture | 50x200mm standard; 76.2x12.7mm (358 mesh) available for high security | EN 10223-7 |

| Material | Low Carbon Steel Wire (e.g., Q195/Q235 grade) | ASTM A641, EN 10223-7 |

| Surface Treatment | Hot-dip Galvanized then PVC Coated OR Hot-dip Galvanized then Powder Coated | EN ISO 1461 (Galvanization), ISO 9227 (Salt Spray), ASTM B117 |

| Coating Thickness (Powder) | Min. 80 microns, typically 100-120 microns | ISO 2808 |

| Coating Thickness (PVC) | Min. 400 microns, typically 450-500 microns | ISO 2808 |

| Tensile Strength | 500-700 MPa (post-drawing) | EN 10218-2 |

| Post Diameter | 60x60mm square, 60mm round, or 75x75mm square - various options | Manufacturer Internal |

| Service Life Expectancy | 20-30+ years with proper installation and maintenance | Accelerated Weathering Tests |

The selection of wire diameter, mesh size, and coating type directly impacts the fence's security level, rigidity, and resistance to environmental degradation. For instance, the tight mesh of a 358 anti climb fence variant prevents handholds and footholds, making it virtually impossible to scale without specialized tools, while the coating galvanized steel wire mesh fencing panels ensure superior weather resistance.

Figure 1: High-security odm 7' security fence featuring 3D curved panels.

Diverse Application Scenarios and Target Industries

The robust design and superior protection offered by the odm 7' security fence make it an ideal choice across a spectrum of demanding industries and critical infrastructure projects. Its inherent properties, such as high anti-corrosion and anti-climb capabilities, ensure reliability in harsh or high-risk environments.

- Petrochemical and Energy Sector: For oil refineries, gas storage facilities, power plants, and renewable energy sites, perimeter security is non-negotiable. The corrosion resistance of PVC/powder coated coating galvanized steel wire mesh fencing panels is crucial against chemical exposure and saline environments, ensuring long-term asset protection. The 358 anti climb fence variant is particularly favored here due to its high deterrence.

- Metallurgy and Mining: Securing valuable raw materials, processing plants, and equipment yards against theft and unauthorized access. The durability of the odm 7' security fence stands up to heavy industrial conditions.

- Water Supply & Drainage Facilities: Protecting reservoirs, pumping stations, water treatment plants, and critical pipelines from contamination and sabotage. The eco-friendly coatings also ensure no adverse impact on water quality.

- Data Centers and IT Infrastructure: High-security perimeters are essential to protect sensitive data and hardware. The anti-climb features of the odm 7' security fence provide an initial layer of defense against physical breaches.

- Transportation Hubs: Airports, seaports, railway depots, and logistics centers require secure boundaries to control access and prevent illicit activities. The 3d curved welded wire mesh fence panel design offers enhanced aesthetic integration while maintaining high security.

- Military and Government Installations: Where national security is paramount, these fences provide a formidable physical barrier against unauthorized entry.

- Commercial and Industrial Parks: Securing business assets, warehouses, and manufacturing facilities from theft and vandalism, reducing insurance costs and improving overall safety.

In these scenarios, the advantages of energy saving in manufacturing, coupled with exceptional corrosion resistance and a prolonged service life, translate directly into reduced operational costs and enhanced security posture for businesses.

Technical Advantages and Performance Metrics

The technical superiority of the odm 7' security fence stems from its carefully engineered design and advanced material science. These advantages translate into tangible benefits for critical infrastructure projects and commercial enterprises alike.

- Superior Corrosion Resistance: The dual-layer protection of hot-dip galvanization followed by PVC or powder coating provides an unparalleled defense against rust, chemical exposure, and UV degradation. This system is proven to withstand over 1000 hours of salt spray testing (ASTM B117), ensuring decades of maintenance-free operation even in harsh coastal or industrial environments.

- High Anti-Climb & Anti-Cut Capabilities: Especially with the 358 anti climb fence mesh aperture (76.2x12.7mm), it's virtually impossible to grip or cut with standard tools. This "prison mesh" design significantly deters intruders, making it ideal for high-security applications. The robust wire diameter and welding integrity further enhance resistance to forced entry.

- Enhanced Structural Rigidity: The 3d curved welded wire mesh fence panel design incorporates horizontal V-bends that dramatically increase panel strength and resistance to bending or deformation, reducing the need for additional support structures. This inherent strength reduces material fatigue over time.

- Eco-Friendly & Sustainable: Our ECO Friendly Fence utilizes PVC/powder coatings that are lead-free and comply with environmental regulations. The extended service life minimizes replacement cycles, reducing waste and contributing to lower carbon footprints over the fence's lifecycle.

- Low Maintenance Requirement: Thanks to the durable coating galvanized steel wire mesh fencing panels, periodic painting or anti-corrosion treatments are unnecessary, significantly lowering the total cost of ownership.

- Rapid Installation: The modular design of the panels and posts, combined with specialized fixing clips, allows for swift and efficient installation, minimizing project timelines and labor costs.

Figure 2: Detail of the secure mesh and post connection of an odm 7' security fence.

Vendor Comparison: Why Choose a Specialized 358 Anti Climb Fence Supplier

When procuring a high-security fencing solution like the odm 7' security fence, selecting the right vendor is paramount. Not all 358 anti climb fence suppliers or 358 anti climb fence manufacturers offer the same level of expertise, quality, and service. A direct comparison highlights the value of specialized providers.

Key Differentiators in Vendor Selection:

| Feature | Specialized 358 Anti Climb Fence Supplier | General Fence Manufacturer / Distributor |

|---|---|---|

| Product Quality & Standards | Adheres to strict international standards (ISO, ASTM, EN). Consistent wire diameter, weld strength, and coating thickness. Certifications readily available. High-grade raw materials. | Varies greatly. May use lower-grade materials or less precise manufacturing, leading to inconsistent quality and reduced longevity. Limited certifications. |

| Customization Capabilities | Offers comprehensive tailored solutions for fence height, panel width, mesh size, wire gauge, and specific coating types (PVC vs. Powder) to meet unique project requirements. Deep engineering expertise for complex projects. | Limited customization, typically offering standard sizes and finishes. May struggle with specialized requests or unique site conditions. |

| Technical Support & Expertise | Dedicated technical teams for design, engineering, and installation support. Can provide detailed CAD drawings, stress analyses, and on-site consultation. Expertise in 358 anti climb fence service. | Basic product information; limited engineering or design support. May lack deep understanding of complex security requirements. |

| Lead Time & Logistics | Efficient production lines and established logistics networks ensure reliable lead times and global delivery, supported by experienced 358 anti climb fence exporters. | Lead times can be unpredictable, especially for non-standard orders. Logistics may be less optimized, leading to delays. |

| Warranty & After-Sales | Comprehensive warranties (e.g., 10-20 years on coating) backed by established quality control. Responsive after-sales support for any issues. | Shorter or less clear warranties. After-sales support may be limited or outsourced. |

| Pricing & Value | While initial 358 anti climb fence quotes might seem higher, the long-term value from superior durability, lower maintenance, and guaranteed performance results in a lower Total Cost of Ownership (TCO). | Lower upfront cost but often leads to higher TCO due to premature failure, increased maintenance, or inadequate security. |

Partnering with experienced 358 anti climb fence factories and 358 anti climb fence suppliers like us ensures access to cutting-edge manufacturing, engineering excellence, and reliable project execution for your odm 7' security fence needs.

Customized Solutions for Unique Security Challenges

Every security project presents a unique set of challenges, from undulating terrain to specific threat assessments. Recognizing this, leading manufacturers of the odm 7' security fence offer comprehensive customized solutions to ensure optimal performance and seamless integration.

- Tailored Dimensions: Beyond the standard 7-foot height, fences can be custom-fabricated to heights up to 12 feet or more, with varying panel widths to minimize cutting and waste on-site.

- Mesh Configurations: While the 358 anti-climb mesh is standard for high-security, other mesh apertures can be customized for specific visual permeability or aesthetic requirements.

- Coating Options: Choice between robust PVC coating for extreme corrosive environments or high-adhesion powder coating for superior UV stability and color customization (RAL colors).

- Post and Fixings: Various post types (square, round, rectangular hollow section) and anti-tamper fixing mechanisms are available to suit ground conditions and security levels.

- Integrated Security Features: Seamless integration with razor wire, barbed wire, electric fencing, CCTV mounting brackets, and access control systems for a multi-layered security approach.

- Gate Systems: Matching swing gates, sliding gates, and cantilever gates, all fabricated with the same high-security panels and coating, ensuring consistent aesthetics and protection.

Our expert engineers engage in detailed consultations to understand project specific needs, providing CAD designs and structural analyses to ensure that the customized odm 7' security fence solution perfectly aligns with security objectives and budget constraints.

Application Case Studies & Customer Success

The proven reliability of our ECO Friendly Fence PVC / Powder Coated 3D Curved Welded Wire Mesh Fence is best demonstrated through real-world applications and positive customer feedback. As a leading 358 anti climb fence supplier and 358 anti climb fence manufacturer, we have deployed advanced fencing solutions across diverse high-stakes environments.

- Case Study 1: Major European Data Center (2019-2021)

Challenge: Secure a new 15-acre data center facility requiring Level 3 perimeter protection against sophisticated intrusion attempts, with a focus on long-term, low-maintenance operation.

Solution: Installation of 4.5 km of odm 7' security fence, specifically 358 anti-climb mesh with hot-dip galvanized and PVC fusion-bonded coating. Integrated with CCTV posts and fiber optic intrusion detection systems.

Outcome: Zero perimeter breaches reported since installation. Customer feedback highlighted exceptional durability against severe weather conditions and significant cost savings on maintenance compared to previous installations. The tight mesh prevented even small animals from entering. - Case Study 2: Coastal Petrochemical Plant, Middle East (2020-2022)

Challenge: Protect critical processing units from unauthorized access and the corrosive effects of a highly saline, humid environment, requiring a fence with superior anti-corrosion properties and a 20+ year service life.

Solution: Custom-designed odm 7' security fence panels, featuring enhanced hot-dip galvanization (min. 85 microns) followed by a 500-micron thick PVC coating. Specialized anti-climb tops were integrated.

Outcome: Independent inspection after 2 years confirmed zero signs of corrosion or degradation. The client reported enhanced peace of mind and satisfaction with the fence's performance under extreme conditions, citing its "unmatched resilience." This project exemplifies the value offered by reputable 358 anti climb fence service providers. - Case Study 3: International Airport Perimeter Upgrade, Asia (2021-2023)

Challenge: Upgrade existing perimeter fencing to meet international aviation security standards, requiring a highly secure, visually unobtrusive solution that could be rapidly deployed without disrupting airport operations.

Solution: Deployment of a 7-foot tall odm 7' security fence using 3d curved welded wire mesh fence panel design for aesthetic appeal and increased rigidity, with a dark green powder coating for blending into the landscape. Quick-install post systems were utilized.

Outcome: The project was completed ahead of schedule. Security audits confirmed the fence exceeded the required standards for intrusion deterrence. The airport authority praised the discreet appearance and the robustness of the system.

Ensuring Trustworthiness: FAQs, Lead Times, Warranty & Support

Building trust with our B2B partners is foundational. We ensure transparency in our processes, commitments, and support for every odm 7' security fence project.

Frequently Asked Questions (FAQ):

Q1: What is the typical lead time for an odm 7' security fence order?

A1: Standard orders typically have a lead time of 3-4 weeks from order confirmation. Customized solutions or very large projects may require 5-8 weeks. We provide a precise timeline with every 358 anti climb fence quotes.

Q2: What warranty is provided for the coating galvanized steel wire mesh fencing panels?

A2: We offer a comprehensive 10-year warranty against manufacturing defects and coating degradation (e.g., severe peeling, cracking, or premature rust-through) under normal environmental conditions for both PVC and powder-coated finishes. This can be extended up to 20 years for specific high-performance coatings or project types, as agreed.

Q3: Can the fence be installed on uneven terrain?

A3: Yes, the modular design and post installation methods allow for adaptation to undulating terrains. Our technical team can provide detailed guidance and custom panel designs to accommodate slopes and curves effectively, ensuring the integrity of the odm 7' security fence remains uncompromised.

Q4: Are your fences compliant with international security standards?

A4: Absolutely. Our products adhere to or exceed relevant international standards such as ISO 9001 (Quality Management), EN 10223-7 (Welded Steel Wire Mesh Fences), ASTM A641 (Zinc-Coated Carbon Steel Wire), and ISO 9227/ASTM B117 (Salt Spray Testing). We are committed to maintaining the highest quality for our B2B clients, as expected from a leading 358 anti climb fence manufacturers.

Lead Time & Fulfillment:

Our streamlined manufacturing processes and robust supply chain enable us to manage project timelines efficiently. For urgent requirements, we offer expedited production options. All orders are meticulously inspected and packaged to prevent damage during transit, ensuring on-time and intact delivery through our reliable network of 358 anti climb fence exporters.

Comprehensive Customer Support:

From initial consultation to post-installation support, our dedicated customer service team and technical experts are available to assist. We provide detailed installation guides, technical drawings, and troubleshooting support. Our commitment extends throughout the entire lifecycle of your odm 7' security fence, ensuring long-term satisfaction and optimal security performance.

Conclusion: A Strategic Investment in Perimeter Security

The selection of a perimeter security system is a critical decision for any B2B entity. The ECO Friendly Fence PVC / Powder Coated 3D Curved Welded Wire Mesh Fence, as a leading odm 7' security fence solution, offers an unmatched combination of technical superiority, environmental responsibility, and long-term cost-effectiveness. Its robust construction, advanced anti-corrosion treatments, and formidable anti-climb design make it an indispensable asset for protecting critical infrastructure and valuable assets across diverse industries.

By understanding the detailed manufacturing process, comprehensive technical specifications, and broad application potential, businesses can make informed decisions that safeguard their operations, meet regulatory requirements, and ensure peace of mind for decades to come. Partnering with a specialized and reputable 358 anti climb fence supplier guarantees not just a product, but a complete, reliable, and sustainable security solution.

References:

- International Organization for Standardization (ISO). (n.d.). ISO 9001: Quality management systems – Requirements. Retrieved from www.iso.org

- ASTM International. (n.d.). ASTM A641/A641M-09: Standard Specification for Zinc–Coated (Galvanized) Carbon Steel Wire. Retrieved from www.astm.org

- European Committee for Standardization (CEN). (n.d.). EN 10223-7: Steel wire and wire products for fencing and netting - Part 7: Steel welded panels for fencing. Retrieved from standards.cencenelec.eu

- NACE International (now AMPP). (n.d.). Corrosion Engineering Handbook. Retrieved from www.ampp.org

- The Galvanizers Association. (n.d.). Hot Dip Galvanizing: A Guide to Best Practice. Retrieved from www.galvanizing.org.uk