Sep . 14, 2025 08:00 Back to list

ODM 7' Security Fence: High-Security, Anti-Climb Steel Mesh

Elevating Perimeter Security: The Advanced odm 7' security fence Solution

In the realm of critical infrastructure and high-value asset protection, the demand for robust, reliable, and aesthetically integrated perimeter security solutions is paramount. Modern industrial and commercial facilities require fencing systems that not only deter unauthorized access but also withstand harsh environmental conditions and offer long-term performance with minimal maintenance. This article delves into the technical intricacies, manufacturing excellence, and strategic advantages of the odm 7' security fence, focusing on its role in diverse B2B applications.

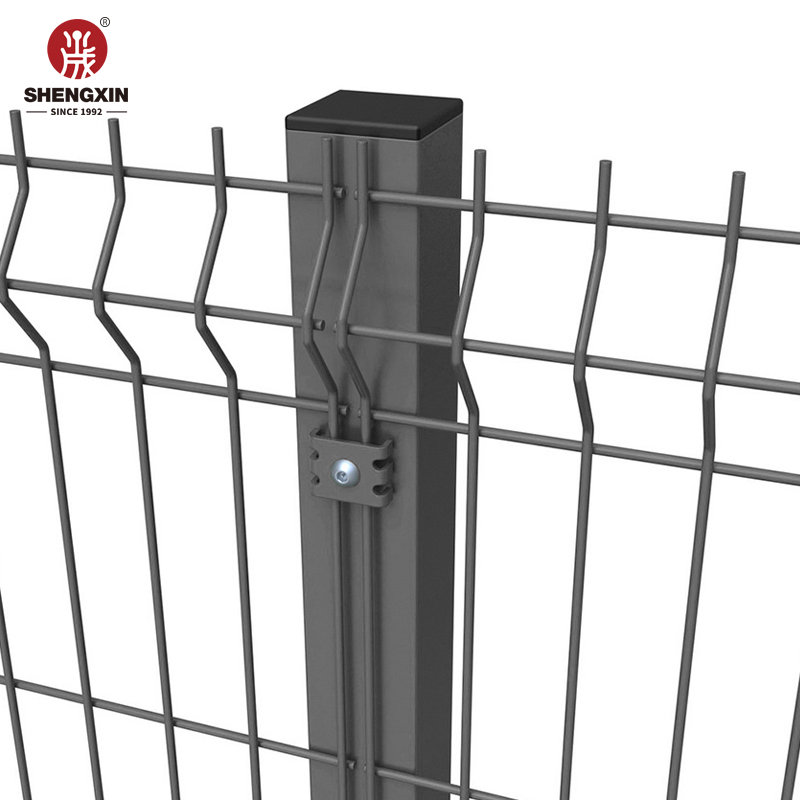

Specifically, we will explore the ECO Friendly Fence PVC / Powder Coated 3D Curved Welded Wire Mesh Fence, a product engineered to meet stringent security requirements while adhering to environmental sustainability. This 7-foot security fence represents a blend of advanced materials science and precision manufacturing, offering unparalleled protection for a variety of sectors, from petrochemical plants to public utilities. Understanding its design, production, and deployment is crucial for decision-makers seeking optimal security investments.

Industry Trends in Perimeter Security Solutions

The global security fencing market is experiencing significant evolution, driven by increasing threats, technological advancements, and a heightened focus on environmental responsibility. Key trends include:

- Integration with Smart Technologies: Modern perimeter fences are increasingly integrated with surveillance systems, access control, and IoT sensors to create comprehensive security ecosystems.

- Enhanced Anti-Climb Features: The demand for fences resembling the formidable 358 anti climb fence is growing, with designs minimizing foot and hand holds. Our odm 7' security fence incorporates similar principles, offering exceptional deterrence.

- Sustainable Materials and Processes: A shift towards eco-friendly materials and manufacturing processes, such as lead-free PVC or low-VOC powder coatings, is gaining traction. The ECO Friendly Fence exemplifies this trend.

- Corrosion Resistance and Durability: For long-term asset protection, the longevity of materials like coating galvanized steel wire mesh fencing panels is a critical factor, reducing maintenance costs and ensuring consistent performance.

- Customization and Scalability: Clients require flexible solutions that can be tailored to specific site conditions and security threat levels, from standard panels to bespoke designs.

These trends underscore the importance of selecting a security fence that not only meets current needs but is also adaptable to future security challenges and environmental standards.

Technical Specifications and Parameters

The performance of any security fence hinges on its precise technical specifications. The odm 7' security fence, specifically the ECO Friendly Fence PVC / Powder Coated 3D Curved Welded Wire Mesh Fence, is engineered with meticulous attention to detail, ensuring superior structural integrity and protective capabilities. Its design incorporates 3D curved sections which significantly enhance rigidity and aesthetic appeal compared to flat panels.

| Parameter | Specification Detail |

|---|---|

| Panel Height | 7 feet (approx. 2.13 meters) - Custom heights available |

| Panel Width | 2.0m, 2.5m, 3.0m (approx. 6.5ft, 8.2ft, 9.8ft) |

| Wire Diameter | 3.0mm - 6.0mm (Gauge 11 - Gauge 4) |

| Mesh Opening | 50x100mm, 50x150mm, 50x200mm, 60x150mm (Varies by security level) |

| Post Dimensions | Square posts (e.g., 60x60mm, 80x80mm), Rectangular posts (e.g., 60x80mm, 80x100mm) |

| Surface Treatment | Hot-dip Galvanized + PVC/Powder Coated (Minimum 80 microns coating thickness) |

| Tensile Strength | Typically 500-700 MPa (Pre-coated steel wire) |

| Service Life | 20+ years under normal conditions (Dependent on coating quality and environment) |

These specifications underscore the robust construction of the 3d curved welded wire mesh fence panel, designed for enduring security and resilience against environmental degradation.

Manufacturing Process Flow for odm 7' security fence

The production of a high-quality odm 7' security fence is a multi-stage process, meticulously controlled to ensure adherence to international standards like ISO 9001 and ASTM. Our manufacturing expertise ensures each component contributes to the fence's overall strength and durability.

1. Material Procurement & Wire Drawing

High-carbon steel rods are sourced, rigorously tested for chemical composition and mechanical properties. These are then drawn into specific wire diameters, ensuring uniform tensile strength and ductility.

2. Precision Welding

Individual wires are arranged and precisely welded using automated machinery to form the mesh panels. This process ensures consistent mesh openings and strong, clean weld points, crucial for the integrity of the 3d curved welded wire mesh fence panel.

3. 3D Curving (Bending)

The flat welded panels undergo a bending process to create the distinctive 3D curves. These curves are not merely aesthetic; they significantly increase the panel's rigidity and resistance to impact and bending forces.

4. Surface Treatment: Galvanization

Panels are meticulously cleaned and then hot-dip galvanized. This process forms a robust metallurgical bond between the steel and a protective zinc layer, offering superior cathodic and barrier corrosion protection.

5. Surface Treatment: PVC/Powder Coating

After galvanization, a high-adhesion PVC or polyester powder coating is applied electrostatically and then cured. This dual-layer system forms coating galvanized steel wire mesh fencing panels, providing exceptional UV stability, abrasion resistance, and an additional layer of corrosion protection, extending the fence's service life beyond 20 years.

6. Quality Control & Testing

Each batch undergoes rigorous testing, including adhesion tests, salt spray tests (ASTM B117), impact resistance tests, and visual inspections to ensure compliance with ISO and ANSI standards. This guarantees the fence meets advertised durability and protective qualities.

This comprehensive process ensures that every odm 7' security fence panel leaving our factory is of the highest quality, ready for deployment in demanding environments.

Technical Advantages and Performance

The inherent design and material selection of our odm 7' security fence confer numerous technical advantages vital for B2B security applications:

- Superior Corrosion Resistance: The dual-layer protection of hot-dip galvanization followed by PVC or powder coating provides exceptional resistance to rust, chemicals, and weathering. This is crucial for long-term performance in coastal, industrial, or polluted environments, offering an estimated service life of over 20 years.

- Enhanced Structural Rigidity: The 3D curved profile of the 3d curved welded wire mesh fence panel significantly increases its strength-to-weight ratio. This design makes the fence highly resistant to bending, cutting, and impact forces, making it more difficult for intruders to breach.

- Anti-Climb Deterrence: While not a full 358 anti climb fence (which typically has very small apertures), the mesh sizes used in our 7-foot panels are carefully selected to minimize hand and foot holds, making climbing extremely difficult without specialized tools, thus providing a strong deterrent.

- Low Maintenance: The robust coating system eliminates the need for frequent painting or specialized upkeep, translating into significant long-term cost savings for facility managers. Its resistance to UV degradation prevents fading and chalking.

- Environmental Sustainability: Being an "ECO Friendly Fence," it utilizes materials and processes designed to minimize environmental impact, including lead-free coatings and adherence to strict emission standards during manufacturing.

- Energy Efficiency in Production: Optimized manufacturing processes are employed to reduce energy consumption, contributing to lower carbon footprints, an increasingly important factor for environmentally conscious organizations.

These advantages collectively ensure a secure, durable, and sustainable perimeter solution for demanding industrial and commercial settings.

Application Scenarios and Target Industries

The versatility and high-security features of the odm 7' security fence make it an ideal choice for a broad spectrum of industries requiring robust perimeter protection:

- Petrochemical Facilities: Securing refineries, chemical plants, and storage depots where high-value assets and hazardous materials demand maximum protection and corrosion resistance.

- Metallurgy and Heavy Industry: Protecting foundries, steel mills, and mining operations from unauthorized entry, safeguarding equipment and personnel.

- Water Supply & Drainage Systems: Essential for securing reservoirs, pumping stations, water treatment plants, and critical pipeline infrastructure against vandalism and sabotage.

- Industrial Parks and Warehousing: Defining boundaries, controlling access, and enhancing the security of large industrial complexes and logistics centers.

- Power Plants and Utility Substations: Protecting vital energy infrastructure from tampering and intrusion, ensuring continuous operation.

- Telecommunications and Data Centers: Guarding sensitive equipment and information against physical threats.

- Transportation Hubs: Airports, seaports, and railway yards benefit from durable and high-security fencing to control access and enhance safety.

In these scenarios, the fence's ability to resist harsh environmental conditions, combined with its robust physical barrier, provides an energy-saving solution by minimizing the need for constant human patrolling and frequent repairs. Its longevity also contributes to lower lifecycle costs, making it a sustainable investment.

Customized Solutions for Perimeter Security

Recognizing that every B2B client has unique security needs and site specificities, we offer extensive customization options for the odm 7' security fence. As a leading 358 anti climb fence supplier and 358 anti climb fence manufacturer, our capabilities extend beyond standard offerings to provide tailor-made solutions:

- Height and Width Variations: While 7-foot is standard, we can customize panel heights and widths to precisely match site requirements and security threat assessments.

- Wire Gauge and Mesh Size: Adjustable wire diameters and mesh apertures for varying levels of security, including options that approach the tight mesh of a traditional 358 anti climb fence.

- Coating Colors and Types: A wide array of RAL colors for PVC or powder coating to blend with architectural aesthetics or corporate branding. Specialized coatings for extreme environments (e.g., anti-graffiti, marine-grade).

- Post and Fixing Options: Diverse post types (e.g., square, rectangular, round) with various fixing methods (e.g., in-ground, base plated, wall-mounted) to suit different terrains and installation demands.

- Integrated Security Accessories: Customization includes integration points for barbed wire, razor wire, CCTV cameras, motion sensors, and access control systems, enhancing overall security infrastructure.

- Gate Systems: Bespoke pedestrian gates, single/double swing gates, and sliding gates, all manufactured to the same high standards and coating specifications as the fence panels.

Our experienced team, as dedicated 358 anti climb fence service providers, collaborates closely with clients to develop optimal designs, ensuring functional excellence and compliance with all relevant industry standards.

Vendor Comparison: Choosing Your odm 7' security fence Partner

Selecting the right 358 anti climb fence supplier or 358 anti climb fence manufacturer is critical for ensuring project success and long-term security. While many 358 anti climb fence factories exist, our commitment to quality, engineering excellence, and customer service distinguishes us. Here’s a comparative perspective:

| Feature/Service | Our Offering | Typical Competitor |

|---|---|---|

| Material Quality | High-grade steel, rigorously tested. Certified coating galvanized steel wire mesh fencing panels. | Standard commercial steel, inconsistent galvanization. |

| Coating System | Dual-layer (HDG + PVC/Powder) min. 80 micron, eco-friendly. Long-term warranty. | Single-layer pre-galvanized or thinner post-galvanized, standard powder coat. Shorter lifespan. |

| Manufacturing Standards | ISO 9001 certified, ASTM compliance, advanced automation for consistency. | Basic quality control, manual processes, inconsistent product. |

| Customization & Design | Full ODM/OEM capabilities, engineering support, tailored solutions. | Limited standard options, minimal design flexibility. |

| Technical Support | Dedicated technical engineers, installation guidance, project management. | Basic sales support, little technical expertise. |

| Pricing & Value | Competitive 358 anti climb fence quotes for premium quality and long-term value. | Lower initial cost but higher lifecycle cost due to maintenance/replacement. |

Our long-standing reputation as reliable 358 anti climb fence exporters and partners to major industries speaks to our unwavering commitment to quality and client satisfaction.

Application Case Studies

Real-world deployments demonstrate the effectiveness and reliability of our odm 7' security fence solutions:

Case Study 1: Large-Scale Industrial Complex, Middle East

A major petrochemical company in the Middle East required a robust perimeter solution for its expanding refinery, spanning over 5 kilometers. The environment presented challenges of high temperatures, corrosive air, and the need for stringent anti-intrusion measures. Our customized 7-foot security fence, featuring a heavy-duty hot-dip galvanized and marine-grade PVC coating, was selected. The project involved integrating the fence with a comprehensive CCTV and motion sensor system. After two years in operation, the client reported zero perimeter breaches, minimal maintenance, and excellent resistance to the harsh climate.

“The durability and anti-climb features of this fencing system have exceeded our expectations. It has significantly enhanced our site security with virtually no upkeep, proving to be a cost-effective long-term investment.” - Security Manager, GCC Petrochemical Corp.

Case Study 2: Municipal Water Treatment Plant, North America

A critical municipal water treatment plant faced increasing issues with vandalism and unauthorized access. The project demanded a high-security fence that was also visually unobtrusive. We supplied a bespoke 3d curved welded wire mesh fence panel system, 7 feet tall, with a dark green powder coating to blend with the natural surroundings. The fence's robust construction and tight mesh provided superior deterrence. The installation was completed ahead of schedule, with seamless integration of access gates and monitoring points.

“The new fence provides the peace of mind we needed. Its design is strong yet blends into the landscape, and the installation was professional and efficient. A truly reliable barrier.” - Operations Director, City Water Authority.

Frequently Asked Questions (FAQs)

Q1: What is the typical lead time for an odm 7' security fence order?

A1: Standard orders typically have a lead time of 3-4 weeks from order confirmation to shipment. For large-volume or highly customized projects, lead times may vary, and we provide a detailed timeline during the quotation process. Express options may be available upon request.

Q2: What is the warranty on the coating of your coating galvanized steel wire mesh fencing panels?

A2: We offer a comprehensive 10-year warranty on the PVC/Powder coating against peeling, cracking, or severe fading under normal environmental conditions. This warranty underscores our confidence in the superior quality and durability of our surface treatments, which meet or exceed ISO standards.

Q3: Can your 3d curved welded wire mesh fence panel be integrated with existing security systems?

A3: Yes, our fencing systems are designed for seamless integration with various third-party security components, including CCTV cameras, perimeter intrusion detection systems (PIDS), and access control solutions. Our technical team can provide guidance and assist in designing compatible installations.

Q4: Are your fences truly "ECO Friendly"?

A4: Absolutely. Our ECO Friendly Fence utilizes lead-free PVC and low-VOC powder coatings. Our manufacturing processes are optimized for energy efficiency and waste reduction, aligning with international environmental management standards.

Order Fulfillment: Lead Time, Warranty, and Customer Support

As a dedicated 358 anti climb fence supplier and global exporter, we understand the critical nature of timely delivery and dependable support for B2B clients. Our robust logistics and customer service framework are designed to ensure a smooth procurement and installation experience.

- Lead Time & Fulfillment: We maintain efficient production schedules to provide competitive lead times, typically ranging from 3-6 weeks depending on project complexity and order volume. Our dedicated logistics team manages global shipping to ensure on-time delivery to your project site.

- Warranty Commitments: All our products, including the odm 7' security fence, come with a comprehensive warranty covering material defects and coating integrity (10-year coating warranty). This commitment provides peace of mind and safeguards your investment.

- Customer Support & After-Sales Service: Our expert team provides end-to-end support, from initial consultation and technical specifications to installation guidance and after-sales assistance. We are available to address any inquiries, provide spare parts, or offer troubleshooting to ensure the long-term performance of your security infrastructure. We pride ourselves on being a reliable 358 anti climb fence service provider.

For any inquiries or to obtain specific 358 anti climb fence quotes, please contact our sales and technical support teams. We are committed to fostering long-term partnerships built on trust and superior product performance.

References

- ASTM International. (2018). ASTM A123/A123M-17: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

- ISO 9001:2015. (2015). Quality management systems – Requirements. International Organization for Standardization.

- The Galvanizers Association. (2020). Duplex Systems: Galvanizing Plus Paint or Powder Coating. Retrieved from https://www.galvanizing.org.uk/

-

Durable and Cost-Effective 2mm Chain Link Fence for Global Applications

NewsNov.22,2025

-

Durable & Cost-Effective Chain Link Metal Fence for Diverse Global Needs

NewsNov.22,2025

-

Comprehensive Guide to Lawn Chain Link Fence: Durability, Applications, & Innovations

NewsNov.21,2025

-

Powder Coated Double Wire Mesh Fence - Anping Shengxin

NewsNov.21,2025

-

Chain Link Fence System — Durable, Versatile, and Cost-Effective Fencing Solutions Worldwide

NewsNov.20,2025

-

Durable and Stylish Black Chain Link Fence Gate Solutions for Every Need

NewsNov.19,2025