Oct . 28, 2025 12:15 Back to list

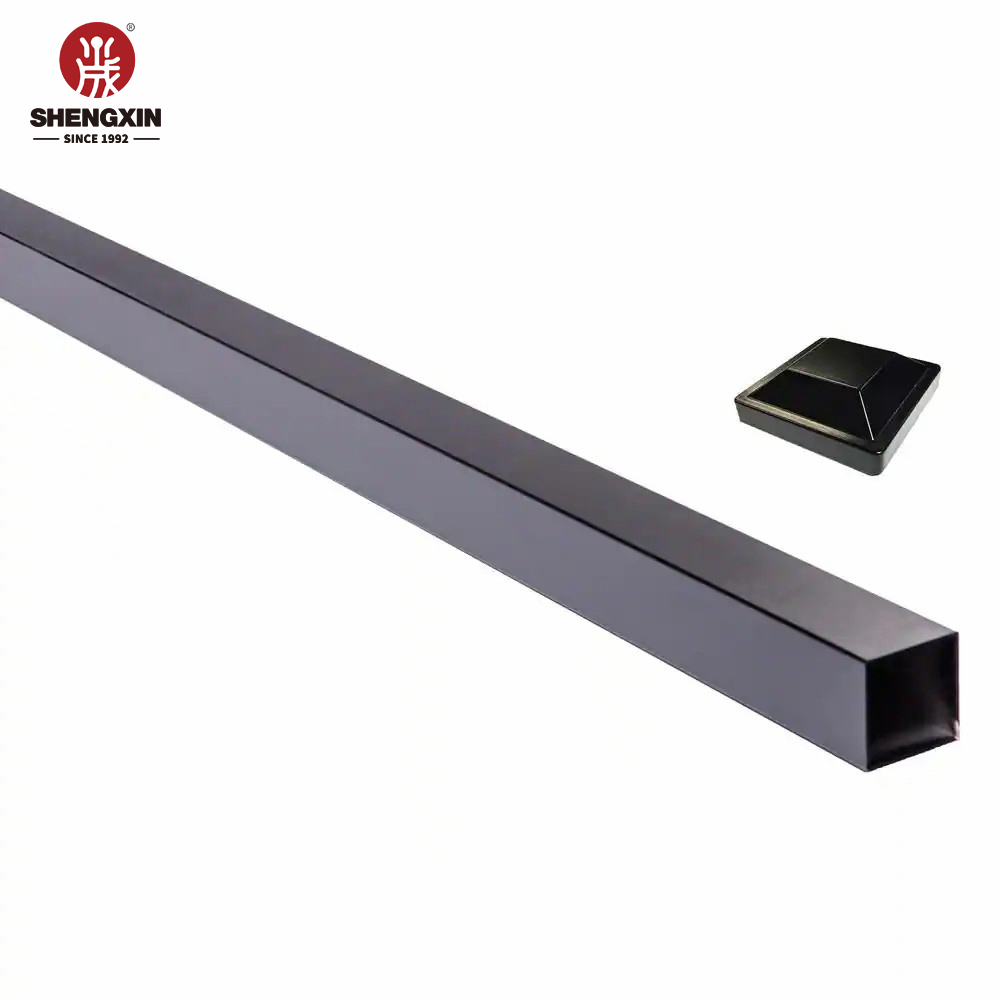

Powder-Coated Square Metal Fence Posts–Decorative, Removable

Powder-coated square posts that actually hold up—without looking like jobsite hardware

If you’ve specced perimeter fencing lately, you’ve probably noticed the quiet shift: architects and facility managers are swapping plain round posts for cleaner square profiles with removable bases. I’ve been watching this space for years, and the product that keeps popping up in site plans is the Powder Coating Square Shape Fence Post Decorative Removable Metal Fencing Posts.

What’s driving the trend

Three factors: faster installs, lower lifecycle cost, and aesthetics. Square posts sit flush against panels, align neatly with base plates, and—oddly important—photograph well for project handovers. Municipal buyers tell me they like the “finished” look. Contractors like that the removable sockets let them reconfigure lines for events or phased builds without core drilling every time.

Core specs (field-proven, not wishful)

| Parameter | Typical value (≈ / around) |

|---|---|

| Steel grade | Q235/Q355, mild steel; hot-dip galvanized (HDG) or pre-galv |

| Section sizes | 50×50, 60×60, 75×75 mm; custom on request |

| Wall thickness | ≈1.2–3.0 mm (real-world use may vary by wind zone) |

| Coating | Polyester powder, 60–120 μm; AAMA 2604-level finish target |

| Colors | RAL palette (popular: 6005, 7016, 9005) |

| Removal method | Lockable sleeves/base plates with anti-theft fasteners |

| Service life | ≈15–25 years in C3–C4 environments with maintenance [2] |

| Testing targets | Adhesion ASTM D3359 4B–5B; Salt spray ASTM B117 500–1,000 h |

| Origin | North of Houzhuang Village, Anping County, Hengshui, Hebei, China |

How they’re made (short version)

- Materials: Q235/Q355 square tube, base plates, caps.

- Prep: Precision cutting, MIG welding; burr removal.

- Corrosion base: HDG to ISO 1461 or pre-galv tube; sweep blast to Sa 2.5.

- Pretreatment: degrease, rinse, iron/zirconium phosphate; DI rinse.

- Powder: electrostatic spray; cure profile ≈180–200°C for 10–15 min (substrate temp).

- QA: Adhesion ASTM D3359, impact ASTM D2794, hardness ASTM D3363, thickness ISO 2360, salt spray ASTM B117; color ΔE checks; optional UV per AAMA 2604 protocol.

Where they excel

- Municipal parks and schools—clean geometry, safe rounded caps.

- Residential perimeters—pairs nicely with welded mesh panels.

- Events/retail—removable posts for flexible layouts, to be honest, a lifesaver.

- Industrial/logistics—base plates over utilities; no core drilling.

- Coastal installs—spec heavier galvanizing and thicker powder for C4–C5.

Why this model stands out

The Powder Coating Square Shape Fence Post Decorative Removable Metal Fencing Posts system leans into modularity: sleeves, anti-theft hardware, and repeatable hole patterns. Many customers say installation time drops by around 20–30% compared to site-bored posts. And yes, it looks tidy—less “temporary site,” more “designed.”

| Vendor | Coating (≈μm) | Customization | Lead time | Certs |

|---|---|---|---|---|

| Anping manufacturer (this product) | 80–120 | Sizes, RAL, caps, base plates | ≈15–25 days | ISO 9001; test to ASTM/ISO |

| Generic import | 50–80 | Limited | ≈30–45 days | Factory CoC only |

| Big-box house brand | ≈60 | Standard SKUs | In stock (limited) | Basic QA; no AAMA data |

Mini case notes

Coastal marina, NSW: Up-spec’d to HDG + 100–120 μm powder, RAL 7016. After 14 months, adhesion rated 5B; only fastener bloom noted. Client feedback: “Surprisingly solid in storm gusts.”

Logistics park, NL: Removable sleeves used along dock aprons. Installers reported ≈25% faster setup; seasonal reconfiguration completed over a weekend instead of a week.

Checklist before you buy

- Ask for adhesion (ASTM D3359) and salt spray (ASTM B117) reports.

- Confirm coating class vs. environment per ISO 12944 (C2–C5).

- Specify base plate thickness and anchor layout; wind zone matters.

- Request AAMA 2604/2605 compliance if intense UV exposure is expected.

Standards and references:

- ASTM B117, D3359, D2794, D3363—coating durability and adhesion tests.

- ISO 12944—corrosion protection of steel structures by protective paint systems.

- AAMA 2604/2605—voluntary specs for high-performance powder coatings.

-

Fancy Chain Link Fence – Durable, Stylish, and Sustainable Fencing Solutions

NewsNov.24,2025

-

Comprehensive Guide to Chain Fence Link Sets: Benefits, Applications, and Trends

NewsNov.23,2025

-

Durable and Cost-Effective 2mm Chain Link Fence for Global Applications

NewsNov.22,2025

-

Durable & Cost-Effective Chain Link Metal Fence for Diverse Global Needs

NewsNov.22,2025

-

Comprehensive Guide to Lawn Chain Link Fence: Durability, Applications, & Innovations

NewsNov.21,2025

-

Powder Coated Double Wire Mesh Fence - Anping Shengxin

NewsNov.21,2025