Feb . 13, 2025 19:33 Back to list

Galvanized Australia Temporary Fence

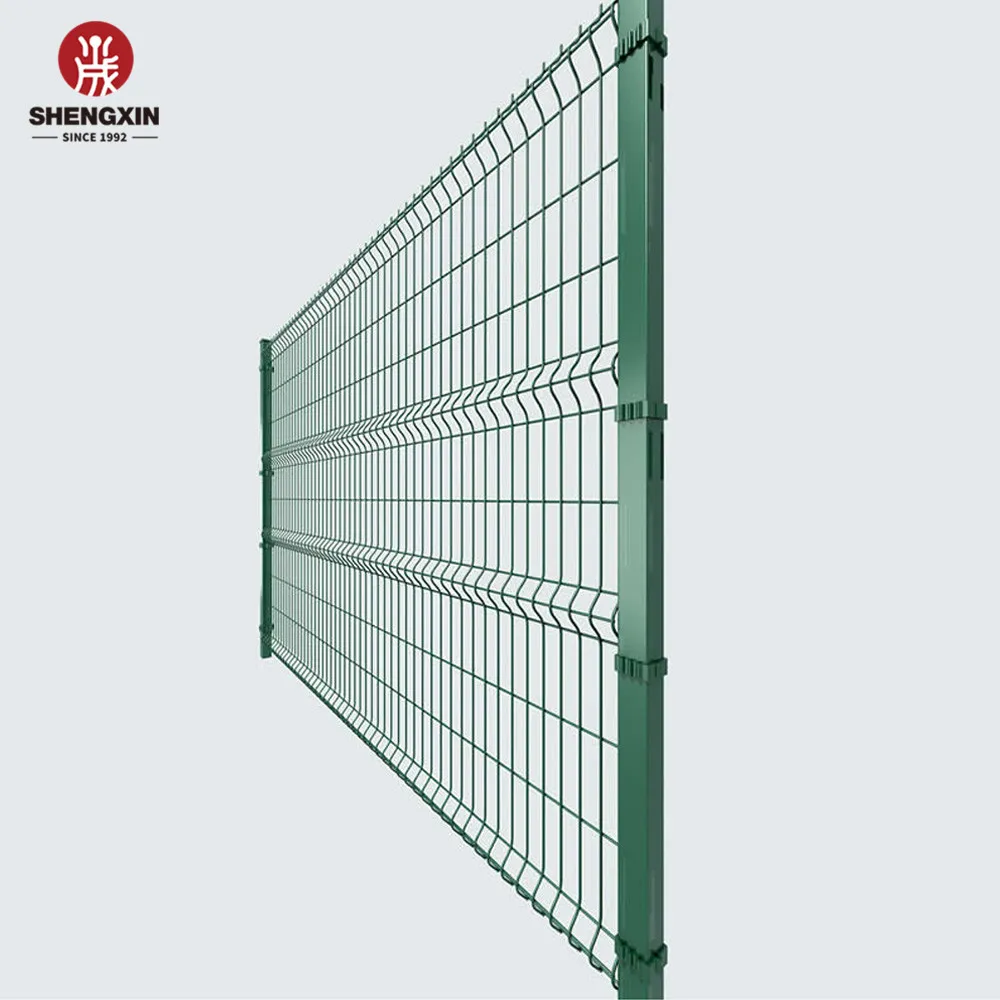

Powder coating technology has revolutionized the fencing industry, and the introduction of the powder painting line for 3D fences marks a significant leap in how durable and attractive these structures can be. With the demand for sustainable and aesthetically pleasing fencing solutions on the rise, understanding the intricacies of this advanced painting line can enhance the decision-making process for stakeholders in the construction and manufacturing domains.

The credibility of powder coating as a method for enhancing 3D fences is backed by numerous industry regulations and standards that sanction its use. These standards ensure that the coating process does not compromise the mechanical properties of the fence material. By adhering to stringent guidelines, manufacturers can assert their commitment to quality and safety, strengthening trust with clients and partners. Furthermore, firsthand experiences from users of powder-coated 3D fences paint a picture of satisfaction and reliability. Reports often cite the visually appealing finish alongside tangible reductions in maintenance as key advantages. This firsthand feedback, coupled with data-rich case studies, adds layers of credibility to the narrative advocating for powder painting lines. To truly harness the benefits of a powder painting line for 3D fences, an ongoing commitment to research and development is paramount. Emerging technologies and materials continue to shape the fencing industry, and staying abreast of these developments ensures that manufacturers can offer state-of-the-art solutions. Integration of automated systems, for instance, can lead to even greater efficiencies and precision in the coating process, ultimately enhancing product output. In summary, adopting a powder painting line for 3D fences presents a host of advantages, from environmental benefits to increased product durability and enhanced aesthetics. Mastery of this technology requires both technical expertise and strategic foresight. By investing in this innovative process, companies not only refine their product lines but also position themselves as leaders and innovators in the fencing industry, forging a path that prioritizes sustainability, quality, and customer satisfaction.

The credibility of powder coating as a method for enhancing 3D fences is backed by numerous industry regulations and standards that sanction its use. These standards ensure that the coating process does not compromise the mechanical properties of the fence material. By adhering to stringent guidelines, manufacturers can assert their commitment to quality and safety, strengthening trust with clients and partners. Furthermore, firsthand experiences from users of powder-coated 3D fences paint a picture of satisfaction and reliability. Reports often cite the visually appealing finish alongside tangible reductions in maintenance as key advantages. This firsthand feedback, coupled with data-rich case studies, adds layers of credibility to the narrative advocating for powder painting lines. To truly harness the benefits of a powder painting line for 3D fences, an ongoing commitment to research and development is paramount. Emerging technologies and materials continue to shape the fencing industry, and staying abreast of these developments ensures that manufacturers can offer state-of-the-art solutions. Integration of automated systems, for instance, can lead to even greater efficiencies and precision in the coating process, ultimately enhancing product output. In summary, adopting a powder painting line for 3D fences presents a host of advantages, from environmental benefits to increased product durability and enhanced aesthetics. Mastery of this technology requires both technical expertise and strategic foresight. By investing in this innovative process, companies not only refine their product lines but also position themselves as leaders and innovators in the fencing industry, forging a path that prioritizes sustainability, quality, and customer satisfaction.

Latest news

-

Durable Chain Link Temporary Fence | Quick Setup & Security

NewsAug.05,2025

-

Coated Galvanized Steel Wire Mesh Fencing Panels | Durability & Protection

NewsAug.04,2025

-

Powder Coated Double Wire Mesh Fence-Anping County Shengxin Metal Products Co., Ltd

NewsAug.03,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd

NewsAug.03,2025

-

Power Coated 358 Anti Climb Mesh Fence for Airports

NewsAug.03,2025

-

Powder Coated Double Wire Mesh Fence-Anping County Shengxin Metal Products Co., Ltd.

NewsAug.02,2025