Oct . 01, 2025 11:00 Back to list

Secure coating galvanized steel wire mesh fencing panels?

Why Zn–Al Galfan Is Changing the Game for Chain-Link Fences

If you’ve been pricing coating galvanized steel wire mesh fencing panels lately, you’ve probably noticed a quiet shift: more spec sheets call for zinc–aluminum alloy (aka Galfan) instead of plain zinc. To be honest, the field data behind that shift is compelling—especially where salt, fertilizer, or industrial pollutants are in play.

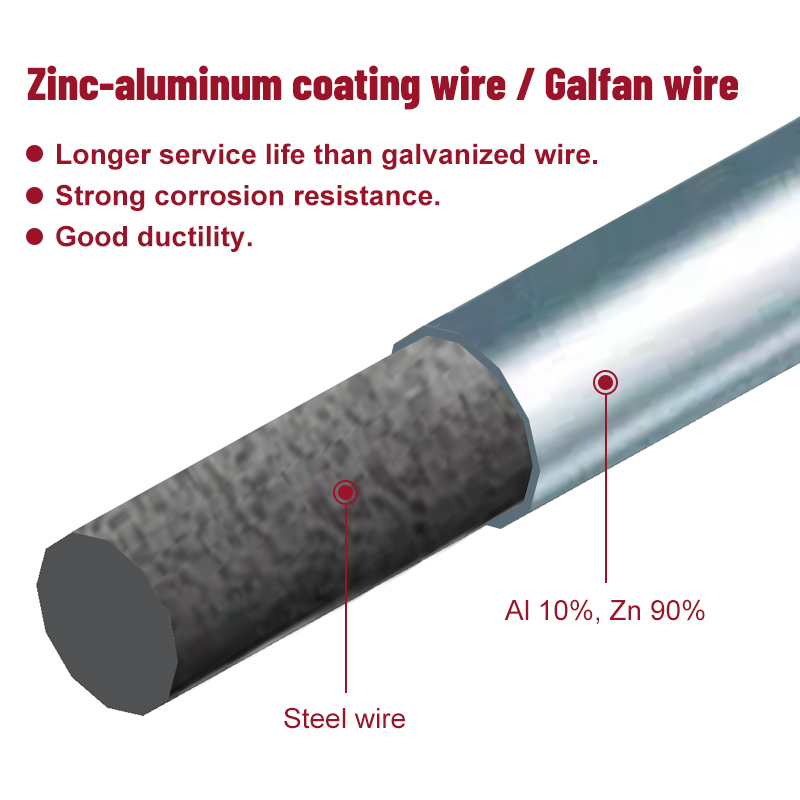

What’s inside the wire (and why it matters)

This product—Zinc-Aluminum Coating Wire / Galfan Wire Chain Link Fence—uses a Zn–Al alloy, typically Al 5%, Zn 95% (sometimes Al 10%, Zn 90%). The alloy forms a compact intermetallic layer that resists red rust far longer than standard zinc. In lab tests we’ve seen, neutral salt spray (ISO 9227) runs >2,000 h without base-metal corrosion, while regular galvanized wire often taps out around 500–720 h. Real-world use may vary, but in coastal districts, I keep hearing “twice the life, sometimes more.”

Typical process flow

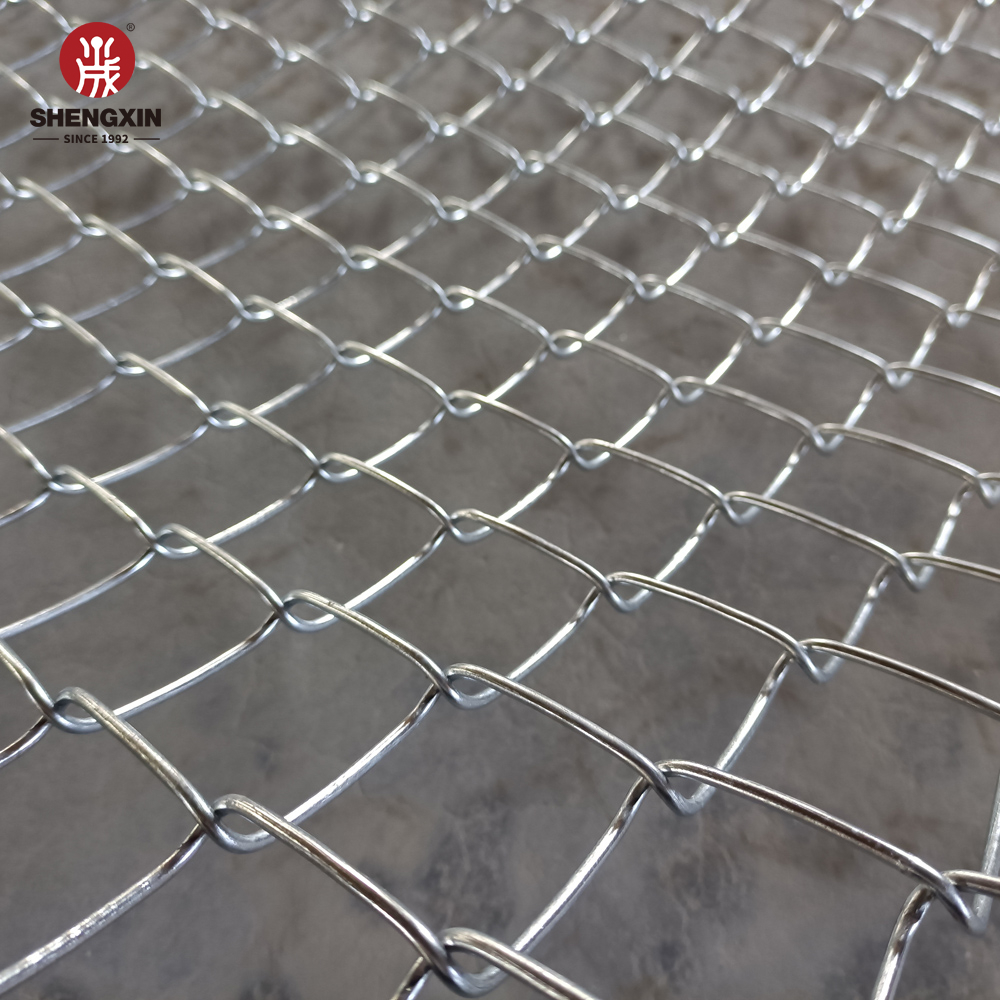

Materials: low-carbon steel rod → wire drawing → cleaning/fluxing → Zn–Al hot-dip coating (ASTM A856/A856M) → controlled cooling → passivation. For fence fabric, the wire is woven into chain-link, then tensioned on site. Methods include bend/adhesion tests, coating mass checks (magnetic or gravimetric), and salt-spray validation per ISO 9227 or ASTM B117. Service life: around 20–35 years inland, 12–25 years coastal, assuming normal maintenance. Weldability and formability are better than thick zinc coatings—installers appreciate that when closing ties or fabricating gates.

| Spec | Typical Range (≈) | Notes |

|---|---|---|

| Alloy | Al 5% / Zn 95% or Al 10% / Zn 90% | Conforms to ASTM A856 classes |

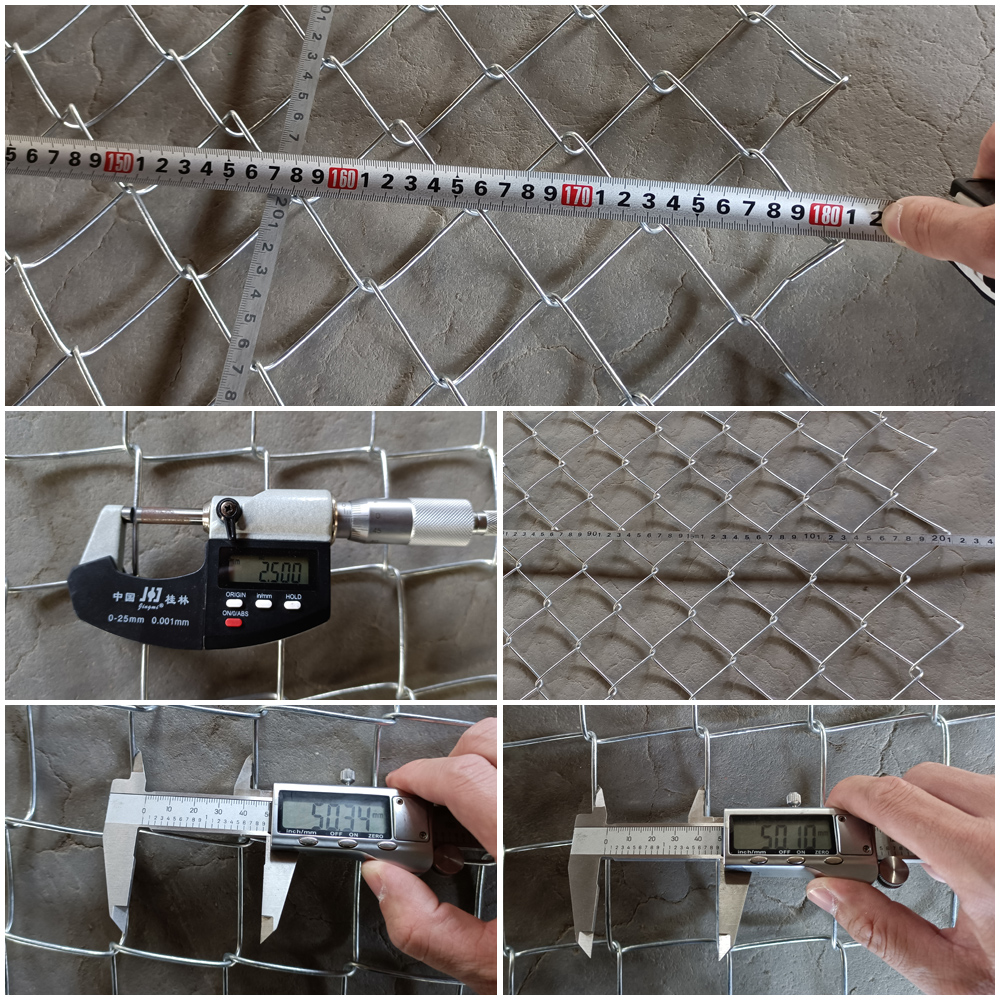

| Wire diameter | 2.1–4.0 mm | Heavier gauges for perimeter security |

| Coating mass | 190–350 g/m² | Measured per EN 10244-2 |

| Mesh aperture | 50×50, 60×60, 75×75 mm | Custom sizes available |

| Fence height | 1.2–3.0 m | With/without barbed arms |

Where it’s used (and what users say)

Airports, substations, sports fields, logistics parks, highway perimeters, solar farms, and coastal aquaculture. Many customers say maintenance cycles fall noticeably, especially in fertilizer-heavy agriculture zones. One facility manager told me, “We stretched repainting from year 4 to year 9—surprising, but we’ll take it.”

Vendor snapshot

| Vendor | Coating Control | Certs | Lead Time | Notes |

|---|---|---|---|---|

| Anping Producer (Hebei, China) | EN 10244-2 Class A/B | ISO 9001; 3rd-party test reports | 2–4 weeks | Stable alloy bath, consistent mesh |

| Generic Importer | Varies | Partial | 4–8 weeks | Check coating mass per batch |

| Local Fabricator | Often zinc-only | Varies | Quick | Good for rush jobs; check standards |

Customization & add-ons

Options include mesh size, height, selvage (knuckle/knuckle or knuckle/barb), tension wire, razor/ barbed arms, gates, and a PVC or powder topcoat over Galfan for extra edge retention. Origin is North of Houzhuang Village, Anping County, Hengshui, Hebei—basically the heartland of metal mesh, where supply chains are dialed in.

Two quick case notes

Coastal fish farm, Qingdao: 2.7 m fence, 60×60 mm mesh, 2.7 mm wire. After 28 months, inspection showed no red rust; minor patina only. Payback vs zinc-only fence estimated at year 3.

Logistics hub, Poland: Winter de-icing salts were chewing up old fabric. Switched to Galfan with powder topcoat. Maintenance tickets dropped ≈40% over two winters. Anecdotal, yes—but echoed elsewhere.

If you’re weighing coating galvanized steel wire mesh fencing panels against Galfan, my take is simple: in mild inland climates, zinc can still be fine. However, anywhere corrosion accelerates—salts, ammonia, industrial fallout—the alloyed route is the smart long-term bid.

References

- ASTM A856/A856M: Zinc-5% Aluminum-Mischmetal Alloy-Coated Steel Wire for Chain-Link Fence Fabric.

- EN 10244-2: Steel wire and wire products — Non-ferrous metallic coatings on steel wire — Part 2: Zinc or zinc alloy coatings.

- ISO 9227: Corrosion tests in artificial atmospheres — Salt spray tests.

- ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods.

-

Durable and Stylish Black Chain Link Fence Gate Solutions for Every Need

NewsNov.19,2025

-

Durable and Versatile Black Chain Link Fence Mesh for Global Use

NewsNov.18,2025

-

Durable 2.5mm Diameter Chain Link Fencing for All Applications | MetalWireFence.com

NewsNov.17,2025

-

Comprehensive Guide to 100 ft Chain Link Fence | Durable & Cost-Effective Security Solutions

NewsNov.15,2025

-

Durable Chain Link Fence with Post – Reliable Industrial Solutions

NewsNov.14,2025

-

Chain Link Fence in Roll – Durable Solutions for Industrial Needs

NewsNov.14,2025