dec . 10, 2024 21:39 Back to list

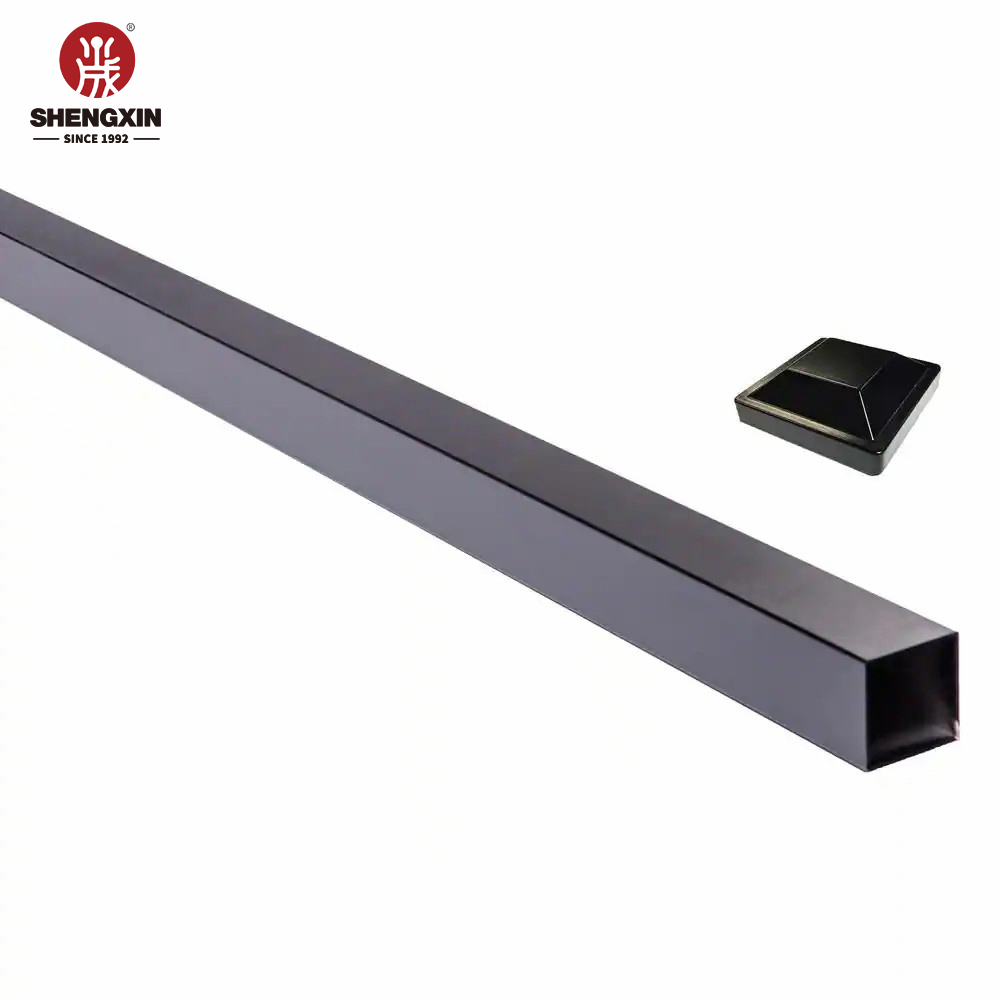

8x8 Durable Metal Fence Panels from Leading Manufacturer for Secure Outdoor Spaces

Exploring the World of 8x8 Metal Fence Panels A Deep Dive into the Factory Process

When it comes to securing properties, enhancing privacy, and improving aesthetic appeal, metal fence panels have become a preferred choice for homeowners and businesses alike. Among various sizes and specifications, the 8x8 metal fence panels have gained significant popularity due to their robust structure, ease of installation, and versatile applications. In this article, we will explore the manufacturing process of these panels in a factory setting, highlighting the craftsmanship and technologies that ensure their durability and quality.

Understanding Metal Fence Panels

Metal fence panels, particularly those measuring 8x8 feet, offer a solid barrier without compromising on design. They are typically crafted from materials like steel or aluminum, which provide superior strength compared to wood or vinyl options. These panels can be used in various applications, from residential yards to commercial properties, offering security while allowing visibility.

The Factory Process From Concept to Creation

1. Design and Prototyping

The journey of an 8x8 metal fence panel begins in the design phase. Engineers and designers collaborate to create detailed blueprints that outline the panel's dimensions, materials, and finish. Advanced software is often used to create prototypes, ensuring that every detail is meticulously planned before moving into production.

Once the design is finalized, the next step is selecting the right materials. Factories typically use high-grade steel or aluminum, chosen for their strength and weather resistance. Some manufacturers also offer galvanized coatings or powder finishes to enhance corrosion resistance, making the panels last longer in various environmental conditions.

3. Cutting and Shaping

The manufacturing process kicks into high gear with the cutting and shaping of metal sheets. Using precision laser cutting machines, the factory staff cuts the metal sheets to the specified dimensions of 8x8 feet. This stage is crucial as it determines the overall appearance and structural integrity of the fence panels.

8x8 metal fence panels factory

4. Welding and Assembly

After cutting, the individual components are carefully welded together. Skilled technicians use MIG or TIG welding techniques to ensure strong joints, critical for maintaining the fence's stability under stress. Automated welding robots may also be deployed to achieve uniformity and efficiency, making the process faster while maintaining high quality.

5. Surface Treatment

Once the panels are assembled, they undergo surface treatment processes. This step includes cleaning, galvanizing, or powder coating, depending on the desired finish. Galvanizing provides a protective zinc coating to prevent rust, while powder coating allows for a variety of colors and designs, enhancing aesthetic appeal.

6. Quality Control

Quality assurance is an integral part of the manufacturing process. Each panel is subjected to rigorous testing for durability, strength, and overall quality. This can involve stress tests, inspections for weld integrity, and assessments of the finish. Factories often have dedicated quality control teams to ensure that each product meets regulatory standards and customer expectations.

7. Packaging and Distribution

Once the panels pass quality checks, they are cleaned and packaged for distribution. Factories use durable packaging materials to protect the panels during transport. Efficient logistics systems are in place to ensure that these panels reach retailers or directly to customers swiftly and in optimal condition.

Conclusion

The 8x8 metal fence panels manufactured in factories represent a blend of engineering precision, advanced technology, and skilled craftsmanship. As demand for robust fencing solutions continues to grow, these panels not only fulfill functional needs but also enhance property aesthetics. Understanding the intricacies of their manufacturing process can help consumers appreciate the value and durability of metal fence panels, making them a wise investment for anyone looking to enhance their property’s security and appearance. Whether you need a fence for privacy, protection, or decoration, the journey from factory to your yard undoubtedly highlights the quality embedded in each panel.

-

868 and 656 Wire Fence Factory & Suppliers - Durable Security Fencing Solutions

NewsJun.24,2025

-

FENC 3D Mesh Fence – Durable, Secure & Easy Installation Custom Quotes & Factory Direct Supply

NewsJun.10,2025

-

Decorative Metal Fencing 3D Supplier – Custom Metal Screen Fencing Manufacturer & Pricelist

NewsJun.10,2025

-

High-Quality Metal Fence Panel - Durable Metal Brown Panel Fence Product & Exporter

NewsJun.10,2025

-

Lawn Chain Link Fencing - Durable & Affordable Solutions Secure Lawn Fences

NewsJun.10,2025

-

Heavy-Duty Metal Fence Posts for Deer Control Factory Direct Supplier

NewsJun.10,2025