nov . 09, 2024 10:46 Back to list

Shipping and Packing Solutions for Chain Link Fence Manufacturing Factories

The Importance of Proper Packing and Shipping in Chain Link Fence Manufacturing

In the realm of construction and fencing, chain link fences have established themselves as a widely preferred choice due to their durability, versatility, and cost-effectiveness. However, the journey of these fences from the factory to the end-user involves a critical component that is often overlooked the packing and shipping process. This article delves into the importance of proper packing and shipping in chain link fence manufacturing, highlighting the methods used, the challenges faced, and tips for ensuring safe delivery.

Understanding the Chain Link Fence

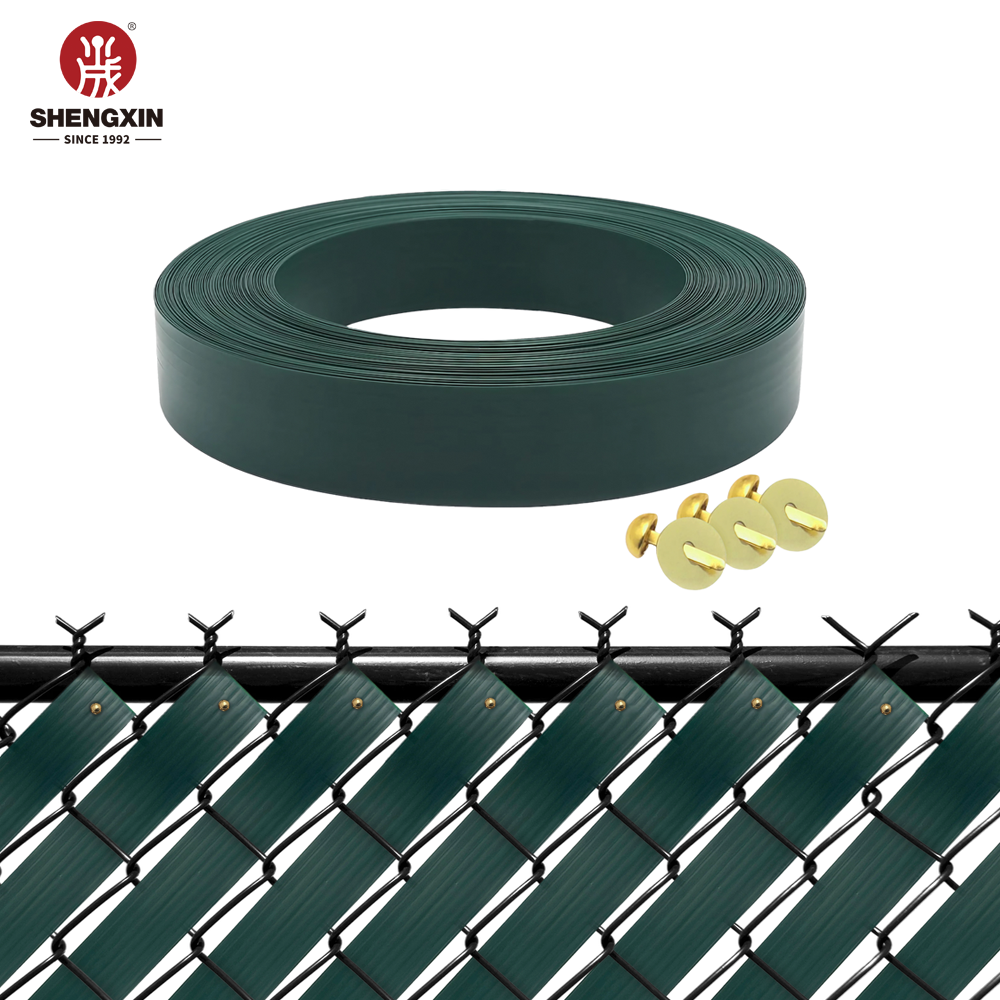

Chain link fences are typically made from galvanized steel wire woven into a diamond pattern. Their design allows for visibility while providing a physical barrier, making them an ideal choice for residential, commercial, and industrial applications. The production process of these fences entails cutting, weaving, and galvanizing the wire, which are usually done in specialized factories.

Packing of Chain Link Fences

Packing is the first line of defense in ensuring that chain link fences arrive at their destination without damage. The typical packing process involves several steps

1. Cutting and Weaving Once the steel wire is processed, it is cut into desired lengths and woven into the mesh form of the chain link. Each roll is crafted with specific dimensions depending on the customer's needs.

2. Quality Control Before packing, a thorough quality check is conducted to ensure that the fence meets industry standards. Any defects or inconsistencies are addressed at this stage.

3. Rolling and Securing Once approved, the chains are rolled tightly to minimize movement during transit. Securing the rolls with durable tape or straps ensures that they maintain their shape and integrity.

4. Cardboard and Plastic Wrapping Each roll is often wrapped with protective materials such as cardboard sheets or plastic film. This protects against environmental elements and physical damage during transit.

5. Palletizing Finally, the packaged chain link rolls are placed on wooden pallets. This method not only makes it easier to handle and transport but also ensures stability, reducing the risk of tipping or falling during shipping.

Shipping Challenges

chain link fence packing&shipping factories

Despite meticulous packing, shipping chain link fences presents its own set of challenges

. Factors such as logistics, distance, and mode of transport play crucial roles in ensuring a successful delivery. Here are some common challenges faced during the shipping of chain link fences- Weather conditions Rain, snow, or extreme heat can affect the integrity of the materials if not properly protected. It’s essential to use waterproof coverings and climate-controlled transport where necessary.

- Transport modes Different modes of transport, whether truck, rail, or sea, come with their own procedures and risks. Proper documentation and adherence to safety regulations are crucial across all transport methods.

- Handling Chain link fences can be heavy and cumbersome, leading to possible damage during loading and unloading. Providing adequate training to personnel on proper handling techniques is critical to prevent mishaps.

Tips for Successful Packing and Shipping

1. Invest in Quality Materials Use high-quality packing materials that can withstand the rigors of transportation. The use of robust pallets, protective wraps, and moisture barriers are essential.

2. Select Reliable Carriers Choose shipping companies with proven track records in handling construction materials. Their expertise can prevent delays and minimize risks.

3. Track Shipments Employ tracking systems to monitor shipments in real time. This helps in identifying potential delivery issues early on.

4. Communicate with Customers Clear communication regarding shipping timelines and processes helps manage customer expectations. Providing updates can enhance customer satisfaction.

5. Continuous Improvement Lastly, regularly review and improve packing and shipping processes based on feedback and challenges encountered. Adaptability and responsiveness are key components to stay competitive in the market.

Conclusion

The effective packing and shipping of chain link fences are paramount to delivering high-quality products to customers. By focusing on proper methodologies, addressing challenges, and maintaining open lines of communication, manufacturers can ensure that their products reach their destinations safely and intact. Proper logistics not only enhances customer satisfaction but also solidifies the manufacturer's reputation in the competitive fencing industry.

-

High-Quality Chain Link Fence Parts Reliable Suppliers & Factory Prices

NewsJul.07,2025

-

Clear View Fence Anti Climb - High Security Fencing Factory & Suppliers Quotes

NewsJul.07,2025

-

Temporary Fence Business for Sale Factory Direct Suppliers & Best Quotes

NewsJul.06,2025

-

High-Quality Temporary Fence Fittings - Trusted Factory & Suppliers Get Quick Quotes

NewsJul.06,2025

-

High Quality 358 Fence High Security Fence Manufacturer Anti-Climb & Durable Solutions

NewsJul.06,2025

-

High-Quality Industrial Security Fence Solutions Reliable Factory & Suppliers

NewsJul.05,2025