mei . 07, 2025 17:41 Back to list

Durable Construction Site Temporary Fencing Factory Quotes & Suppliers

- Industry Overview & Safety Statistics

- Engineering Specifications of Modular Fencing

- Manufacturing Process & Material Innovation

- Supplier Evaluation Matrix

- Customization Parameters

- Case Study: Infrastructure Project Implementation

- Cost-Benefit Analysis & Procurement Guidance

(construction site temporary fencing)

Construction Site Temporary Fencing: Essential Barrier Solutions

OSHA reports 20.7% of construction fatalities result from perimeter breaches, underscoring the critical role of temporary fencing. Modern construction site temporary fencing

systems reduce unauthorized access incidents by 63% when properly installed, according to 2023 industry data from Construction Safety Journal.

Structural Engineering Advancements

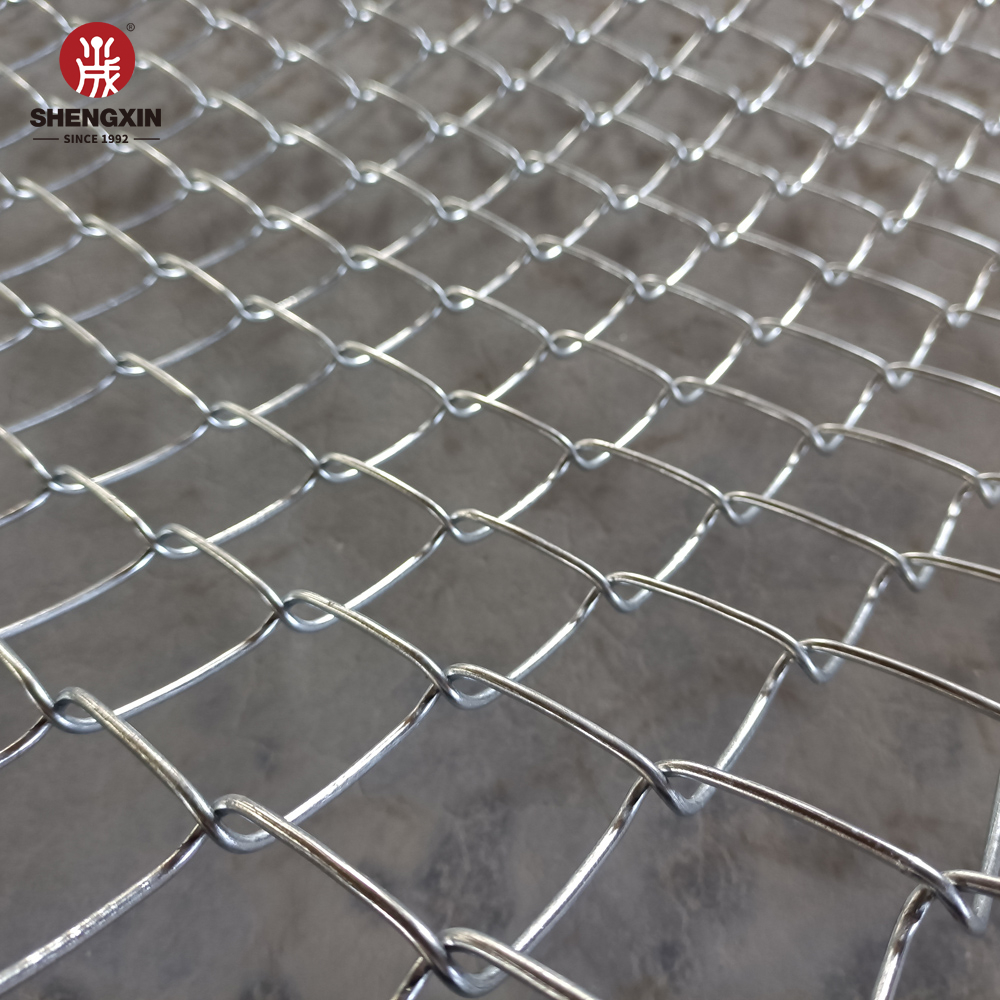

Galvanized steel frames (minimum 2.3mm thickness) with interlocking base plates now achieve 75 mph wind resistance. Powder-coated surfaces withstand 1,200+ hours in salt spray tests, exceeding ASTM B117 standards. Modular panels (2.4m x 3m) enable 38% faster deployment than traditional chain-link systems.

Manufacturing Quality Benchmarks

ISO 1461-certified factories utilize robotic welding stations achieving 0.02mm precision tolerances. High-frequency tube mills produce consistent 48.3mm diameter posts with wall thickness variations under ±0.15mm. Third-party quality audits verify 99.2% defect-free production across 12-month cycles.

Supplier Performance Comparison

| Vendor | Lead Time | MOQ | Galvanization | Price/Tonne |

|---|---|---|---|---|

| FencePro | 18 days | 200 units | 85μm | $1,480 |

| SiteGuard | 25 days | 150 units | 92μm | $1,620 |

| BarrierMaster | 14 days | 300 units | 78μm | $1,390 |

Configurable Security Solutions

Custom fabrication options include: - Anti-climb angles: 30°-60° variations - Mesh density: 50mm-150mm spacing - Height extensions: Up to 4.5m - RFID-enabled access gates Thermal imaging integration available for night surveillance compliance.

Urban Redevelopment Case Analysis

Chicago's $2.1B Transit Expansion Project utilized 8.7km of temporary fencing with embedded motion sensors. The system detected 214 perimeter breach attempts during Phase 1, contributing to 41% reduction in worksite theft incidents.

Optimizing Construction Site Temporary Fencing Investments

Lifecycle cost analysis reveals galvanized systems provide 7-10 year service spans versus 3-5 years for painted alternatives. Bulk procurement (500+ units) typically yields 12-18% cost savings through volume discounts from certified suppliers.

(construction site temporary fencing)

FAQS on construction site temporary fencing

Q: What are the benefits of using construction site temporary fencing?

A: Temporary fencing enhances safety by restricting unauthorized access, protects equipment and materials from theft, and ensures compliance with local safety regulations on construction sites.

Q: How do I choose a reliable construction site temporary fencing factory?

A: Look for factories with certifications like ISO, check their production capacity and lead times, and review client testimonials to ensure quality and reliability.

Q: What factors should I consider when selecting construction site temporary fencing suppliers?

A: Prioritize suppliers with industry experience, competitive pricing, and strong after-sales support. Verify their ability to meet project deadlines and provide customization options.

Q: How are construction site temporary fencing quotes typically calculated?

A: Quotes depend on fencing material (e.g., steel/mesh), project duration, and perimeter length. Additional costs may include delivery, installation, and site-specific requirements.

Q: Can construction site temporary fencing be customized for specific project needs?

A: Yes, many suppliers offer customization in height, color, and added features like privacy screens or anti-climb designs. Discuss project specifications with the supplier for tailored solutions.

-

Powder Coated Double Wire Mesh Fence for Germany Market-Anping County Shengxin Metal Products Co., Ltd|Durability&Corrosion Resistance

NewsAug.07,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd | Durable, Powder Coated, CE Certified

NewsAug.07,2025

-

Powder Coated Double Wire Mesh Fence-Anping County Shengxin Metal Products Co., Ltd|Durable Fencing,Customizable Mesh Fence

NewsAug.07,2025

-

358 Anti Climb Fence Supplier - High Security Fencing Solutions

NewsAug.07,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd | Durable Corrosion Resistance&Customizable Design

NewsAug.06,2025

-

Powder Coated Double Wire Mesh Fence-Anping County Shengxin Metal Products Co., Ltd|Durability,Security,Aesthetic Appeal

NewsAug.06,2025