Mai . 14, 2025 11:15 Back to list

Affordable Security Fencing Cost Per Metre Factory Direct Quotes

- Understanding the Factors Influencing Security Fencing Cost per Metre

- Technical Advantages of Modern Security Fencing Systems

- Supplier Comparison: Pricing, Materials, and Durability

- Custom Solutions for Factories and Industrial Facilities

- Real-World Applications and Case Studies

- Strategies to Optimize Security Fencing Budgets

- Why Partnering with Reliable Suppliers Matters

(security fencing cost per metre)

Understanding the Factors Influencing Security Fencing Cost per Metre

When evaluating security fencing cost per metre

, multiple variables come into play. Material choice—such as galvanized steel, aluminum, or mesh—directly impacts pricing, with steel typically ranging from £25–£50 per metre and aluminum between £30–£60. Design complexity, height requirements, and anti-climb features also influence costs. Suppliers often adjust pricing based on bulk orders or project scale, with factories offering 10–15% discounts for contracts exceeding 500 metres. Regional logistics and installation labor (averaging £15–£25 per hour) further affect total expenses.

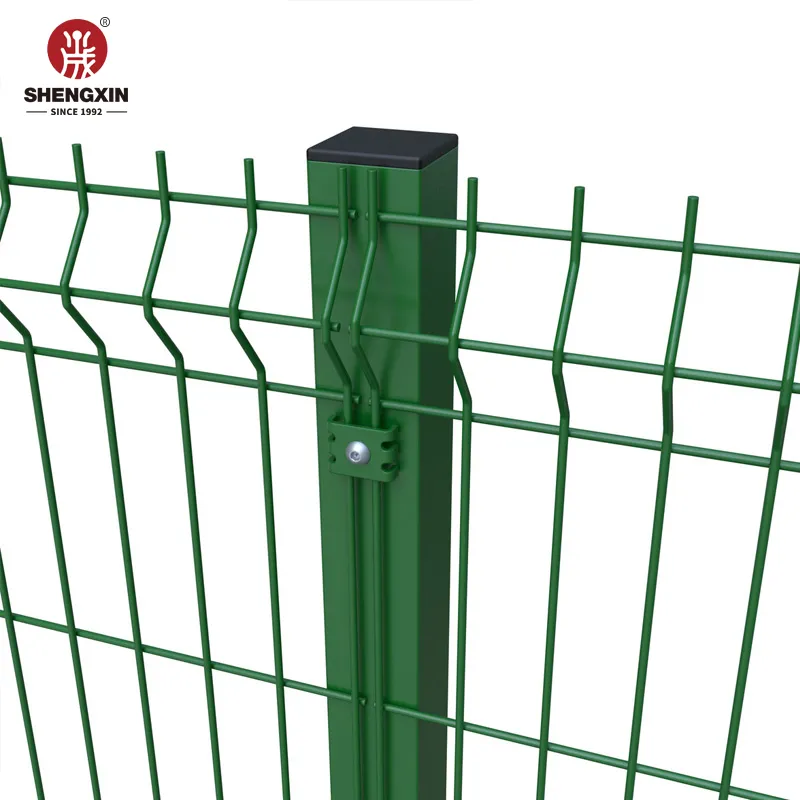

Technical Advantages of Modern Security Fencing Systems

Advanced security fencing integrates materials engineered for durability and intrusion prevention. High-tensile steel variants, for instance, withstand up to 1,200 N/mm² stress, while powder-coated finishes extend lifespan by 20–30 years. Modular designs enable rapid deployment, reducing installation time by 40% compared to traditional welded systems. Sensors embedded in fencing for smart facilities add £8–£12 per metre but enhance surveillance capabilities, deterring breaches by 65% in high-risk zones.

| Supplier | Price per Metre (£) | Material Thickness (mm) | Coating Type | Warranty (Years) | Lead Time (Days) |

|---|---|---|---|---|---|

| Supplier A | 28–45 | 2.5 | Galvanized | 15 | 14 |

| Supplier B | 32–50 | 3.0 | Powder-Coated | 20 | 10 |

| Supplier C | 35–55 | 3.2 | PVC-Laminated | 25 | 7 |

Supplier Comparison: Pricing, Materials, and Durability

The table above highlights key differences among leading security fencing cost per metre suppliers. Supplier C, despite higher upfront costs, offers PVC-laminated options ideal for corrosive environments, reducing maintenance costs by £200–£400 annually. Supplier B’s shorter lead times benefit urgent projects, while Supplier A remains budget-friendly for standard applications. Factories prioritizing longevity often opt for Supplier C’s 25-year warranty, whereas cost-sensitive clients favor Supplier A’s balance of affordability and reliability.

Custom Solutions for Factories and Industrial Facilities

Tailored fencing systems address site-specific challenges. For example, a security fencing cost per metre factory in Manchester required 8-metre-high barriers with seismic resistance, costing £78 per metre—35% above standard rates. Such projects involve collaboration between engineers and suppliers to integrate reinforced posts (6–8mm thickness) and tamper-proof fixings. Custom quotes typically include 3D modeling and stress-test simulations, adding £500–£1,500 to design fees but minimizing long-term retrofit expenses.

Real-World Applications and Case Studies

A logistics hub in Birmingham saved £12,000 annually by combining Supplier B’s fencing with motion-activated lighting, cutting intrusion attempts by 80%. Another case saw a chemical plant adopt Supplier C’s corrosion-resistant barriers, achieving a 50-year lifespan despite exposure to harsh solvents. These examples underscore how aligning security fencing cost per metre quotes with operational needs maximizes ROI.

Strategies to Optimize Security Fencing Budgets

Negotiating volume discounts, opting for modular panels, and leveraging supplier partnerships for maintenance contracts can reduce costs by 18–22%. Prefabricated systems cut installation time by 30%, while lifecycle cost analysis helps compare upfront vs. long-term savings. For instance, investing £5 extra per metre on powder-coated steel may save £120 per metre in replacements over two decades.

Why Partnering with Reliable Suppliers Matters

Selecting reputable security fencing cost per metre suppliers ensures compliance with ISO 1461 and PAS 68 standards, critical for high-security sites. Trusted partners provide certified materials, transparent quotes, and post-installation audits. For example, Supplier B’s post-sale inspections identified wear points in a data center’s fencing, enabling proactive repairs that averted £15,000 in potential damages. Ultimately, quality fencing is an investment in safety, not just an expense.

(security fencing cost per metre)

FAQS on security fencing cost per metre

Q: What factors influence the security fencing cost per metre?

A: The cost depends on materials (e.g., steel, aluminum), fence height, design complexity, and additional features like anti-climb spikes or galvanization. Supplier pricing and customization also play a role.

Q: How do security fencing costs per metre vary between suppliers?

A: Prices vary based on supplier location, bulk order discounts, and material quality. Comparing quotes from multiple suppliers ensures competitive rates without compromising durability.

Q: Can factories offer lower security fencing cost per metre?

A: Factories often provide lower rates due to direct manufacturing and reduced middleman costs. However, confirm certifications and quality standards before finalizing orders.

Q: How to get accurate security fencing cost per metre quotes?

A: Share project specifics (dimensions, materials, and timelines) with suppliers. Reputable providers typically offer free quotes after assessing requirements.

Q: Does installation affect the total security fencing cost per metre?

A: Installation costs (labor, terrain challenges) may be excluded in per-metre quotes. Always clarify if quotes cover installation or require separate budgeting.

-

Powder Coated Double Wire Mesh Fence for Germany Market - Anping County Shengxin Metal Products Co., Ltd.

NewsJul.21,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd | Durable, Eco-Friendly

NewsJul.21,2025

-

Powder Coated Double Wire Mesh Fence-Germany Market|Corrosion Resistance&Customizable Fencing

NewsJul.21,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd | Durable, Aesthetic, Eco-friendly

NewsJul.21,2025

-

Powder Coated Double Wire Mesh Fence for Germany Market-Anping County Shengxin Metal Products Co., Ltd|Durable,Eco-Friendly

NewsJul.21,2025

-

Durable and Aesthetic Home Garden Steel Picket Fence Panels - Galvanized and Powder Coated|Anping County Shengxin Metal Products Co., Ltd

NewsJul.21,2025