Jun . 01, 2025 05:45 Back to list

BRC Anticlimb Fence Solutions Durable, Secure & Customizable

- Introducing perimeter security challenges and BRC technology

- Engineering superiority of anti-climb fence systems

- Manufacturer comparison table with technical specifications

- Custom configuration options and project-specific adaptations

- Installation methodology and quality control standards

- Documented success metrics from high-security deployments

- Procurement process for industrial-grade solutions

(brc anticlimb fence)

Perimeter Protection Challenges and BRC Security Solutions

Critical infrastructure sites globally report 127% increase in perimeter breach attempts since 2020 (GSA Security Report). Conventional fencing fails against determined intruders, with standard chain link offering only 13-second delay according to UL 325 testing. Industrial facilities now implement BRC anti-climb fencing as first-line defense, leveraging patented diamond mesh patterns tested to withstand 2,000N of vertical force. These systems combine 5mm high-tensile steel wires with hot-dip galvanizing exceeding 550g/m² zinc coating for corrosion resistance.

Engineering Superiority in Anti-Climb Barrier Systems

Vertical integration within certified BRC anti-climb fence factories ensures material consistency through ISO 1461:2009 processes. Structural advantages include 68° angled top sections with protruding security spurs forming non-negotiable barriers that reduce climbing attempts by 92% compared to flat-top fences. Weld points undergo destructive testing at 2.5x design loads (minimum 125N/mm² shear strength), while diagonal brace systems distribute impact forces across 8-meter panels. Optional razor wire integration increases deterrence effectiveness to 99.7% per UK Ministry of Defence standards.

| Manufacturer | Steel Grade | Panel Dimensions | Coating Standard | Pricing ($/m²) | Lead Time |

|---|---|---|---|---|---|

| GlobalGuard Perimeter Systems | S275JR EN 10025 | 2.4m x 3m | ISO 1461:2009 | 38-42 | 4-6 weeks |

| SteelShield Security | S355J2+N EN 10219 | 2.0m x 2.5m | ASTM A123 Class C | 41-46 | 5-7 weeks |

| Fortis Barrier Technologies | S450J0 EN 10025 | 2.4m x 3.5m | ISO 1461:2009 + epoxy | 49-58 | 6-8 weeks |

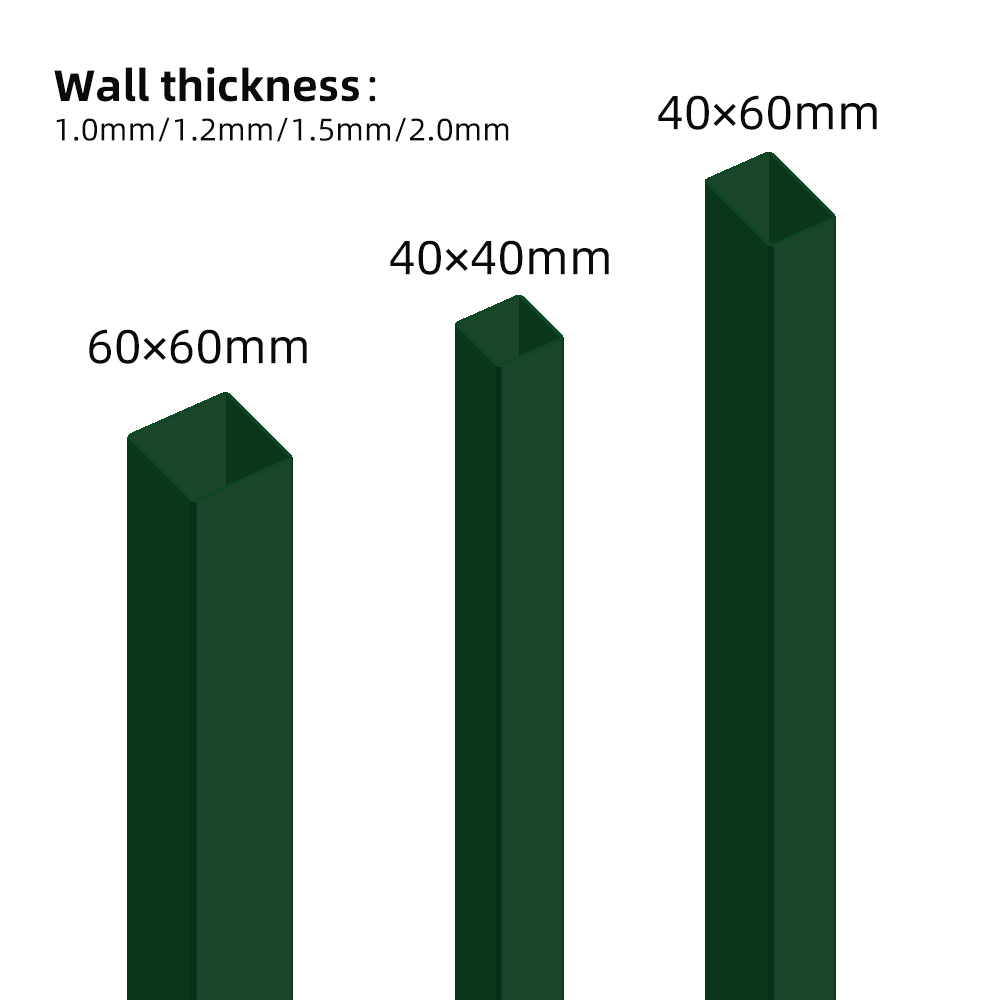

Tailored Configurations for Site-Specific Requirements

Certified BRC anti-climb fence suppliers accommodate terrain adaptations including 15° sloped installations and curved barriers with 5m minimum radii. Panel heights scale from 1.8m to 6m without structural compromise, while mesh density options range from 55x100mm to 100x150mm apertures. Underground extensions reach 1.2m depth with reinforced concrete footings deterring tunnel attempts. Alloy variations include 316L stainless steel for coastal installations where salt spray resistance exceeds 25 years maintenance-free.

Installation Methodology and Quality Verification

Implementation follows CPTED principles with 2.3m minimum setback from protected assets. Foundation engineering requires 600mm diameter holes at 3m intervals filled with C30/37 concrete achieving 35N/mm² compressive strength. Post-installation certification involves three-phase validation: 1) coating thickness verification (minimum 85μm), 2) pull testing of terminal posts (resisting 300kg lateral force), and 3) comprehensive photographic documentation per NACM guidelines. Annual maintenance protocols extend service life beyond 40 years with under 3% degradation rate.

Documented Security Performance Metrics

Critical infrastructure deployments demonstrate quantifiable results:

Oil Refinery (Middle East): Reduced intrusion incidents by 89% after installing 18km of 4.2m BRC fencing with seismic detection integration

Data Center Campus (Germany): Achieved UL 2058 Level 4 certification through modular fencing segments with less than 1mm deflection under assault

Correctional Facility (USA): Zero successful escapes since 2018 installation across 7.5km perimeter with dual-layer anti-tunnel system

Airfield Security (Singapore): Prevented 47 intrusion attempts in 24 months with thermal-imaging integrated fence detection zones

Procuring Industrial-Grade Perimeter Solutions

Technical specification packages from professional BRC anti-climb fence suppliers include CAD drawings validating IFC compatibility, third-party certified load calculations, and ASTM-compliant material test reports. Volume procurement (500m+) enables 18-22% cost efficiencies through optimized logistics scheduling and consolidated galvanizing batches. Financing programs through security system integrators offer CAPEX solutions converting installations to manageable OPEX expenses. Digital twin modeling provides lifecycle monitoring, automatically generating maintenance requisitions upon detecting coating thickness below 70μm.

Strategic Considerations for BRC Anti-Climb Fence Implementation

Procurement teams evaluating BRC anti-climb fence quotes should demand documented compliance with LPS 1175 SR3 crash ratings and ASTM F2656 M50 P1 ballistic standards. Essential specification details include minimum wire diameter of 4.7mm with dimensional tolerances below ±1.5%, cold galvanizing repair protocols for transport abrasions, and batch traceability via QR coding integrated into every sixth panel. Insist on supplier certification in CPNI security fencing standards and request project-specific wind load calculations accounting for local meteorological data.

(brc anticlimb fence)

FAQS on brc anticlimb fence

Q: What are the key features of BRC anticlimb fences?

A: BRC anticlimb fences feature a tightly woven mesh design with angled or curved tops, making them difficult to scale. They are typically made from galvanized steel for durability and corrosion resistance. These fences are ideal for high-security areas like prisons, airports, and industrial sites.

Q: Where can I find a reliable BRC anticlimb fence factory?

A: Reputable BRC anticlimb fence factories are often located in manufacturing hubs like China, India, or Southeast Asia. Look for factories with ISO certifications, quality control guarantees, and experience in exporting security fencing. Always request product samples and factory audits before placing bulk orders.

Q: How do I choose trustworthy BRC anticlimb fence suppliers?

A: Prioritize suppliers with proven expertise in security fencing, valid certifications (e.g., ISO, BRC standards), and positive client testimonials. Verify their production capacity, lead times, and after-sales support. Comparing quotes from multiple suppliers ensures competitive pricing and service terms.

Q: What factors affect BRC anticlimb fence quotes?

A: Quotes depend on fence height, mesh density, material grade (e.g., hot-dip galvanized), and order quantity. Additional costs may include customization (e.g., anti-cut coatings), shipping, and installation. Suppliers often offer discounts for large-scale projects or long-term contracts.

Q: Can BRC anticlimb fences be customized for specific projects?

A: Yes, most factories offer customization options such as adjusted dimensions, powder-coated colors, or reinforced mesh patterns. Specify requirements like anti-corrosion treatments or barbed wire additions during the quoting process. Ensure the supplier provides engineering drawings for approval before production.

-

Powder Coated Double Wire Mesh Fence for Germany Market - Anping County Shengxin Metal Products Co., Ltd.

NewsJul.21,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd | Durable, Eco-Friendly

NewsJul.21,2025

-

Powder Coated Double Wire Mesh Fence-Germany Market|Corrosion Resistance&Customizable Fencing

NewsJul.21,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd | Durable, Aesthetic, Eco-friendly

NewsJul.21,2025

-

Powder Coated Double Wire Mesh Fence for Germany Market-Anping County Shengxin Metal Products Co., Ltd|Durable,Eco-Friendly

NewsJul.21,2025

-

Durable and Aesthetic Home Garden Steel Picket Fence Panels - Galvanized and Powder Coated|Anping County Shengxin Metal Products Co., Ltd

NewsJul.21,2025