Tem . 21, 2024 01:55 Back to list

Designing a Three-Dimensional Bend Fence with ODM for Enhanced Aesthetic and Functional Appeal

Understanding ODM 3D Bend Fences An In-Depth Look

In the realm of modern manufacturing and design, the use of advanced technologies has revolutionized the way we approach various industries. One such innovation that has garnered attention is the ODM (Original Design Manufacturer) 3D bend fence. This technology not only enhances productivity but also ensures precision and versatility in applications ranging from construction to manufacturing.

Understanding ODM 3D Bend Fences An In-Depth Look

One of the primary benefits of utilizing an ODM 3D bend fence is its ability to streamline the manufacturing process. By integrating advanced software and machinery, manufacturers can create a digital prototype and simulate the bending process before physical production begins. This not only reduces material waste but also minimizes the risk of errors that can occur during manual setups. Manufacturers can quickly adjust designs based on real-time feedback from the 3D models, ensuring that the final product meets precise specifications without the need for extensive reworking.

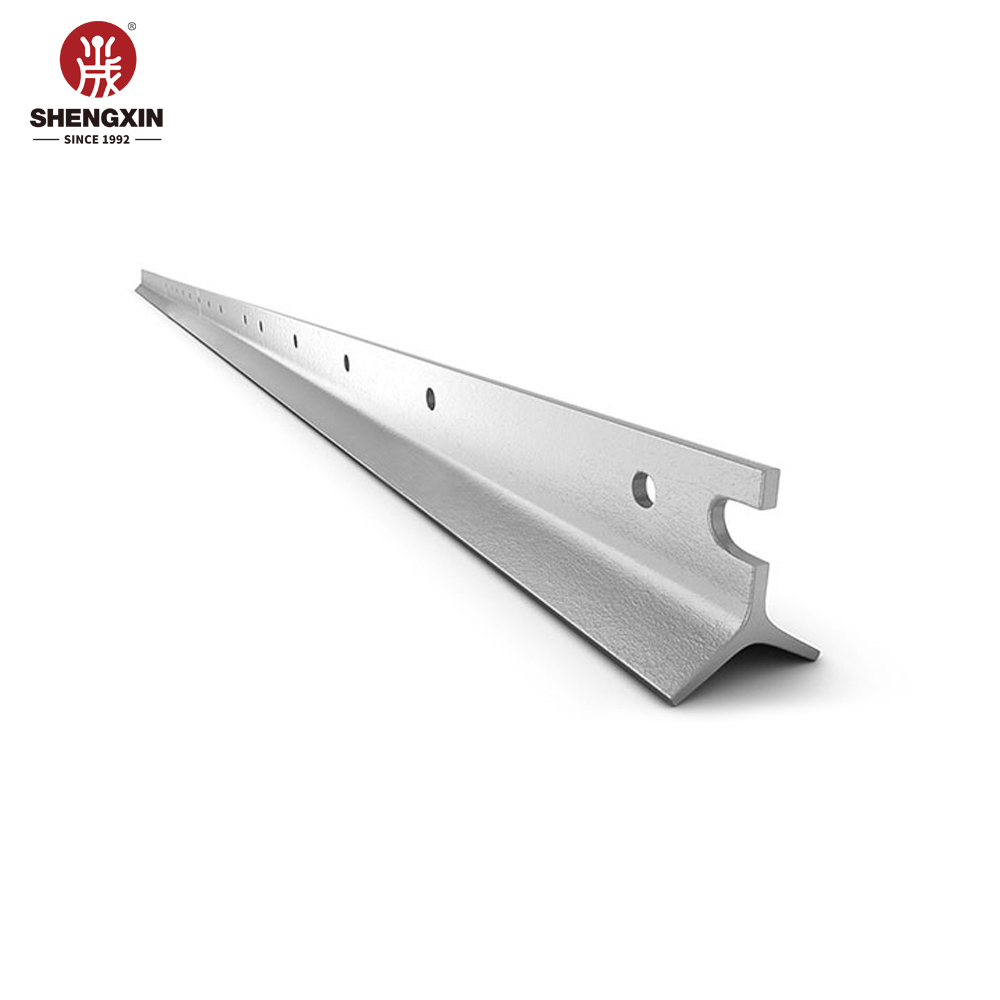

odm 3d bend fence

Moreover, the versatility of the ODM 3D bend fence opens doors to various applications. In construction, for instance, this technology can facilitate the creation of customized metal frames, railings, and architectural features that blend form and function seamlessly. The precision offered by a 3D bend fence allows architects and builders to implement unique designs that were previously challenging or nearly impossible to achieve with conventional methods.

Furthermore, industries like automotive and aerospace benefit immensely from this technology. The lightweight and strong components produced using 3D bending techniques contribute to enhancing overall performance and fuel efficiency. ODM 3D bend fences can create complex parts that fulfill the stringent safety and regulatory standards required in these sectors, all while reducing production times and costs.

The integration of automation is another critical aspect of the ODM 3D bend fence. With the implementation of robotic systems, the bending process becomes not only faster but also more consistent. This reliability is crucial for large-scale production, where maintaining uniformity across numerous components is essential. Consequently, businesses can achieve higher throughput without compromising on quality, thus meeting growing market demands.

In summary, the ODM 3D bend fence has emerged as a game-changer in the manufacturing landscape. Its ability to perform complex bending operations with precision and efficiency makes it invaluable across various sectors, including construction, automotive, and aerospace. As technology continues to evolve, the adoption of such innovative solutions will likely increase, paving the way for even more sophisticated designs and manufacturing processes. Embracing the capabilities of the ODM 3D bend fence not only enhances productivity but also empowers manufacturers to push the boundaries of design and creativity. As industries worldwide strive for greater efficiency and adaptability, the importance of such advanced technologies will undoubtedly grow, setting the stage for a future where innovation remains at the forefront of industrial success.

-

Premium Perforated Metal Fence for Pools Durable & Secure

NewsJun.08,2025

-

Premium Crowd Control Barriers Factories & Exporters for Events

NewsJun.08,2025

-

Heavy-Duty Temporary Fence Clamps Secure & Quick Setup

NewsJun.07,2025

-

Premium Prepainted Galvanized Steel Sheet Fence Durable Supplier

NewsJun.07,2025

-

Chain Link Fence Barriers Factory - Durable Security & Cost-Effective

NewsJun.06,2025

-

Durable Expanded Metal Mesh Fence Security Solutions

NewsJun.06,2025