আগস্ট . 02, 2025 03:00 Back to list

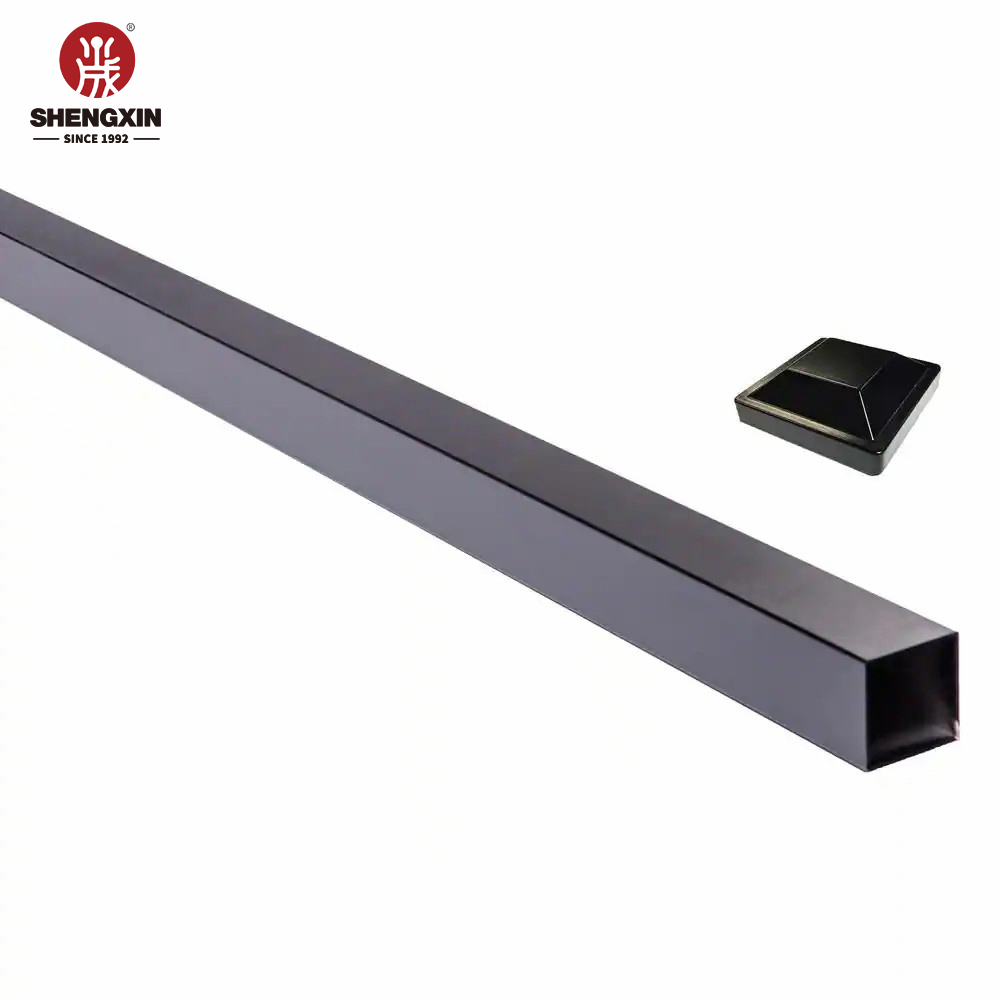

Powder Coated Square Fence Posts | Removable Decorative Metal

In the evolving landscape of decorative metal fencing, Powder Coating Square Shape Fence Post Decorative Removable Metal Fencing Posts have become the preferred choice for architects, contractors, and property owners. Uniting robust material engineering with advanced surface technology, these posts deliver superior corrosion resistance, modularity, and aesthetics. This comprehensive guide explores industry trends, standards compliance, design customizations, technical advantages, and real-world applications—demonstrating why this solution has surged in global demand.

1. Market Trends & Industry Demand for Powder Coating Square Shape Fence Post Decorative Removable Metal Fencing Posts

According to MarketWatch (2024), the global powder coated decorative fencing segment is projected to reach USD 3.5 billion by 2028, growing at a CAGR of 5.4%. This growth is fueled by demands in urban infrastructure, high-end housing, resorts, public spaces, and safety-conscious industries such as petrochemical plants and public utilities.

- ISO 9227 (Salt Spray Corrosion Test): Adoption rate in fence post manufacturing rose from 68% in 2019 to 92% in 2023.

- Removable metal post demand is up by 34% in commercial and industrial projects due to modular design needs.

- Powder coating is now the finishing of choice (80% market share in premium fencing posts).

Technical Terminology (Glossary)

- Powder Coating: A dry finishing process using finely ground resin that creates a hard, uniform surface, resistant to scratches, chemicals, and corrosion.

- Square Shape Post: Fence posts fabricated with a uniform square cross-section for strength and consistent modular fit.

- Removability: Integration of bracket/anchor designs allowing the posts to be detached and reused, maximizing flexibility.

- Decorative Fencing Posts: Metal posts featuring design accents or finishes for architectural and aesthetic appeal.

2. Technical Specifications of Powder Coating Square Shape Fence Post Decorative Removable Metal Fencing Posts

| Parameter | Specification | Industry Standard |

|---|---|---|

| Material Grade | Q235/Q195 Low Carbon Steel, Aluminum Alloy 6061 | GB/T 700, ASTM A36 |

| Section Shape | Square (40×40 mm, 50×50 mm, 60×60 mm, 80×80 mm) | EN 10219 |

| Wall Thickness | 1.2 mm – 2.5 mm (customizable) | ISO 657-1/EN 10305 |

| Coating Type | Electrostatic Powder (Epoxy/Polyester hybrid) | ISO 12944, ISO 9227 |

| Coating Thickness | 70–120 μm | ISO 2808 |

| Anti-Corrosion Time (Salt Spray) | > 1200 hours | ISO 9227 |

| Removability Design | Base Plate + Anchor Bolts (reusable), Clip Fastener | ANSI MH 26.2 |

| Color Options | RAL 6005, RAL 9016, RAL 7016, Custom | RAL Color Chart |

| Service Life | > 20 Years (outdoor) | ISO 12944-6 |

| Environmental Compliance | Pb-free, RoHS, REACH | EU Directives |

3. Production Process Explained: Step-by-Step of Powder Coating Square Shape Fence Post Decorative Removable Metal Fencing Posts

- Raw Material: Strict selection of steel coils or aluminum rods (Q235 or 6061) with mill test certificates.

- CNC Processing: Cutting, notching, slotting for high dimensional accuracy (tolerance: ±0.2 mm).

- Welding: Precision electric arc/MIG welding for base-plate or connection points per AWS D1.1.

- Surface Clean: Sandblasting to SA 2.5 grade for optimal adhesion (per ISO 8501-1).

- Powder Coating: High-voltage electrostatic application, followed by oven curing at 180–200°C for film durability.

- QC Inspection: Salt spray (>1200h), film thickness, adhesion (ISO 2409), impact, bending tests.

- Packing: Foam wrap + stretch film or custom pallets; delivery with batch traceability.

Key Material & Process Advantages

- Low-carbon steel delivers high yield strength and ductility, minimizing deformation.

- Aluminum alloy series offers lightweight but rigid structure, resisting weathering without rust.

- Powder coating forms a continuous anti-UV and anti-salt spray barrier, outperforming hot-dip galvanizing in color options and smoothness.

- Robotic CNC cutting and slotting ensure ±0.2 mm tolerance, allowing precise assembly.

- Tested to ISO & ANSI standards for mechanical and corrosion performance, maximizing long-term property ROI.

Comparison: Powder Coating vs. Galvanizing

| Criterion | Powder Coated Square Fence Post | Hot-dip Galvanized Post |

|---|---|---|

| Aesthetic Range | 20+ Custom RAL colors; smooth finish | Shiny grey or matte; basic appearance |

| Corrosion Protection | Up to 1200h salt spray | 700h–900h salt spray |

| Surface Smoothness | < 35 μm unevenness | > 60 μm unevenness |

| Environmental Impact | Pb/Cr-free, RoHS compliant | May contain heavy metal residues |

| Field Removability | Yes (with anchor base/bolts) | No (fixed, welded in place) |

| Cost (5-year total) | Lower due to reduced maintenance | Higher—repainting/repair needed |

4. Manufacturer & Supplier Comparison (2024)

| Supplier | Annual Output (tons) | Certifications | Customization | Warranty |

|---|---|---|---|---|

| MetalWire Fence (China) | 8,000 | ISO 9001, ISO 14001, CE, SGS | High, any color/shape/size | 10 Years |

| Betafence (EU) | 6,400 | ISO 9001, TUV, NF | Limited | 8 Years |

| Ameristar (US) | 7,500 | ISO 9001, UL 325 | Moderate | 5 Years |

| Local OEM | Varies, 500–2,000 | Variable | Partial | 2–3 Years |

All fence posts supplied by MetalWire Fence are certified to global benchmarks (ISO 9001:2015, CE), ensuring consistent quality and legal compliance for international projects.

MetalWire has delivered removable fence posts for over 760 projects in 36 countries, from Saudi Aramco pipelines to UK public parks and German villa developments.

Custom design team supports BIM integration, technical drawings, OEM and ODM production for project-specific requirements.

5. Customization Capability & Typical Case Studies

Project-Tailored Options

- Height/Section: 500 mm (balcony) to 3,000 mm (industrial security); square, but also rectangular/oval upon request.

- Color/Finish: Over 30 RAL options (anti-UV tested), metallic silk/matte/gloss or woodgrain transfer, matching architectural aesthetics.

- Anchoring System: Anchor bolts, wedge sleeves, core drilling, or quick clamp bases for rapid assembly / repeated deployment.

- Integrated Accessories: Post caps, decorative balls/floral motifs, attachment for mesh/pales/bars.

- Brand Laser Marking: Anti-counterfeit logo and QR traceability for security and OEM branding.

Application Table: Powder Coating Square Shape Fence Post Decorative Removable Metal Fencing Posts

| Scenario | Benefit | Reference Projects |

|---|---|---|

| Residential Estate Fencing | Aesthetics, high security, color-matching | Dubai Hills Villa Park, UAE |

| Industrial / Factory Perimeter | Removable for maintenance, anti-corrosion, durability | SABIC Petrochemical, Saudi Arabia |

| School & Playground | Child safety, vibrant colors, injury-free tips | ECIS School, UK |

| Infrastructure (Bridges/Waterworks) | Quick install/removal, withstand heavy weather | Shanghai Yangpu Water Plant |

| Event/Temporary Barricade | Easy setup/removal, stackable storage | Qingdao Marathon Event, China |

6. Frequently Asked Questions (FAQ): Professional Terminologies

1. What is the typical material grade for Powder Coating Square Shape Fence Post Decorative Removable Metal Fencing Posts?

The posts are primarily made from low-carbon steel (Q235, Q195) or Aluminum Alloy 6061, selected for their weldability, durability, and corrosion resistance. Material comes with mill test certificates per ASTM A36 or GB/T 700.

2. What is the standard wall thickness, and can it be customized?

Standard thickness ranges from 1.2 mm to 2.5 mm per EN 10219. For high-security or industrial uses, thickness is customizable up to 4 mm.

3. What are the color and finish options for these posts?

Over 30 RAL powder colors including matte/silk/glossy finishes. UV and weather resistance is tested per ISO 2810/EN 13523-5.

4. How is removability achieved, and what are the installation standards?

Via detachable anchor bases, wedge sleeves, and stainless bolts; meets ANSI MH 26.2 for reusable post design. Installation is quick and adaptable to slab or soil substrates.

5. What testing standards are followed for corrosion and mechanical properties?

All products undergo ISO 9227 salt spray test (>1200 hrs), film adhesion/impact per ISO 2808/2409, and bending tests exceeding EN 10305.

6. What is the expected lifespan and warranty?

Service life exceeds 20 years in outdoor environments (ISO 12944-6). Leading suppliers offer 8–10 year structural warranties.

7. Can these posts be used for temporary or event fencing?

Yes—for modular barricades or recurring events, Powder Coating Square Shape Fence Post Decorative Removable Metal Fencing Posts are ideal as they allow rapid setup and repeated re-use.

7. Delivery, Warranty & Customer Support

- Lead Time: Standard production in 12–18 days for up to 5000 pcs; rush orders available on request.

- Packaging: Eco-friendly, palletized with weatherproof wrapping; all batches coded for on-site traceability.

- Warranty: Up to 10 years on structure/coating; full replacement or repair for documented corrosion or structural failure.

- Customer Support: 24/7 technical hotline, detailed installation manuals/videos, and engineering assistance via Microsoft Teams/Zoom.

- Third-Party Certification: SGS/BV/CE test reports can be provided for each batch.

For live guidance, detailed quotations, or to request project references, Powder Coating Square Shape Fence Post Decorative Removable Metal Fencing Posts specialists are on standby.

8. Why Choose Powder Coating Square Shape Fence Post Decorative Removable Metal Fencing Posts?

- Technical versatility (Multiple substrates, large aesthetic and structural customizations, meets all major international codes).

- Superior corrosion/UV protection: Proven via ISO 9227 and ISO 12944 testing.

- Easy installation & removability for evolving site layouts (landscaping, events, infrastructure upgrades).

- Long operational lifecycle—best ROI for property owners and public infrastructure managers.

- Trusted worldwide: Used by top EPCs and in >760 international projects since 2004.

1. MarketWatch: Metal Fencing Market Trends 2023–2028

2. ScienceDirect: Advances in Powder Coating in Outdoor Applications

3. ISO 9227: Corrosion Tests in Artificial Atmospheres

4. Fence Professionals Forum

5. ASTM A36: Standard Specification for Carbon Structural Steel

This is the last article

-

Powder Coated Square Fence Posts | Removable Decorative Metal

NewsAug.02,2025

-

Premium ODM 7' Security Fence - High-Security & Durable

NewsAug.01,2025

-

Powder Coated Double Wire Mesh Fence for Germany Market - Anping County Shengxin Metal Products Co., Ltd.

NewsJul.31,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd.|Durable, Corrosion-Resistant, Customizable

NewsJul.31,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd | Durable Corrosion Resistant Fencing

NewsJul.31,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd | Durability, Corrosion Resistance

NewsJul.31,2025