Gor . 06, 2025 07:21 Back to list

High-Quality Temporary Fence Fittings - Trusted Factory & Suppliers Get Quick Quotes

- Overview: The Essential Role of Temporary Fence Fittings in Modern Site Security

- Technical Superiority and Material Advancements Driving the Market

- Comparing Leading Temporary Fence Fittings Factories and Suppliers

- Comprehensive Customization Solutions for Diverse Needs

- Case Study: Temporary Fence Fittings in Action Across Industries

- Obtaining Accurate Temporary Fence Fittings Quotes and Cost Analysis

- Conclusion: Choosing the Right Temporary Fence Fittings for Your Project

(temporary fence fittings)

Overview: The Essential Role of Temporary Fence Fittings in Modern Site Security

Temporary fence fittings form the backbone of robust and adaptable site security solutions. These critical components connect, stabilize, and reinforce fencing panels—especially significant in dynamic environments such as construction sites, public events, and controlled access zones. According to the 2023 Global Safety Equipment Report, the temporary fencing market experienced over 8% CAGR growth and exceeded USD 1.4 billion globally, underscoring the massive demand for reliable fittings. The reliability and quality of these fittings directly impact the structural integrity and safety assurance of temporary fencing systems, requiring precision-engineered and durable options for a multitude of applications.

Technical Superiority and Material Advancements Driving the Market

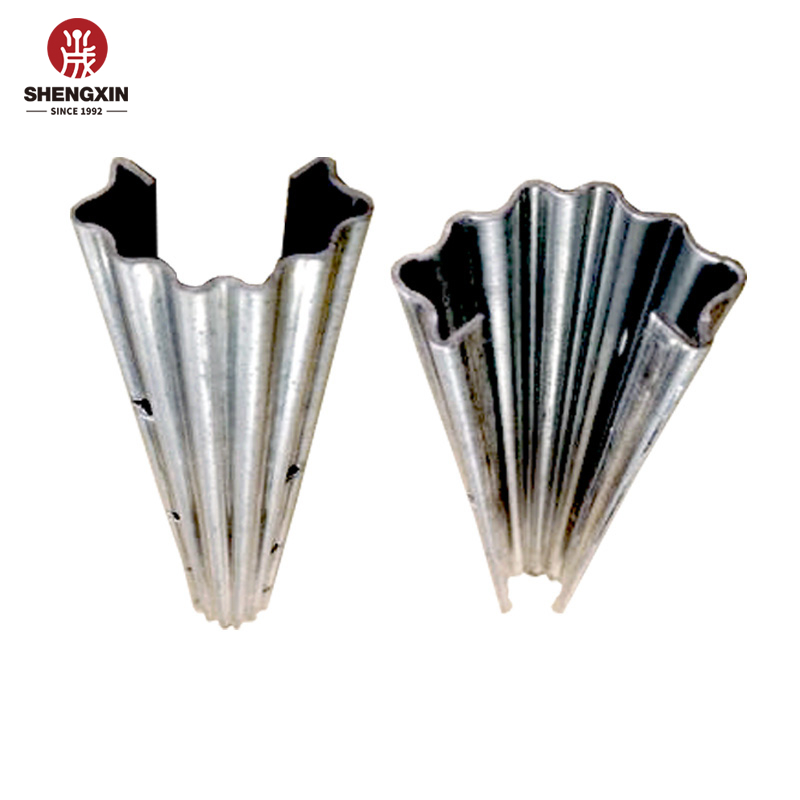

Innovations in manufacturing techniques—such as hot-dip galvanization, powder coating, and use of high-tensile steel—have elevated the performance benchmarks of temporary fence fittings

. Meanwhile, corrosion resistance, UV protection, and extended lifecycle are now baseline expectations from clients. For example, top-tier fittings can withstand wind loads up to 80 km/h and offer rust-resistance with over 300-hour salt spray testing. High-precision welds and reinforced locking mechanisms eliminate weak points and provide tamper-resistant features essential for construction, crowd control, and critical infrastructure protection. These technical advancements have expanded the market reach beyond construction to sectors such as events management, roadside maintenance, and agricultural applications.

Comparing Leading Temporary Fence Fittings Factories and Suppliers

Selecting the right temporary fence fittings supplier is a matter of balancing quality, reliability, pricing, and service. The table below benchmarks three leading factories and their product portfolios, illustrating key comparative data critical for procurement decision-makers:

| Factory / Supplier | Annual Output (Units) | Certifications | Delivery Lead Time | Material Grade | Customization Options | Market Regions |

|---|---|---|---|---|---|---|

| SecureLink Industries | 1,200,000 | ISO 9001, CE | 2 weeks | Q235/Q345 Steel, HDG | Color, Logo Branding | North America, Europe |

| FenceMax Solutions | 950,000 | ISO 14001, SGS | 10 days | Stainless Steel | Specialized Connectors | Australia, Asia |

| UrbanGuard Factory | 1,600,000 | EN 10244, CE | 3 weeks | Galvanized Alloy | Size, Anti-theft Design | Europe, South America |

As shown, each leading temporary fence fittings supplier offers distinctive strengths: from speed and output scale, to customization flexibility and specialized certifications that comply with various regional legislation. Making an informed choice hinges on aligning project-specific demands with supplier capabilities.

Comprehensive Customization Solutions for Diverse Needs

Modern project sites rarely conform to one-size-fits-all solutions; thus, temporary fence fittings manufacturers have invested heavily in offering tailored options. Customization can span across dimensions—material grade, anti-theft features, finish treatments, and integrated branding. For example, event organizers may request fittings with corporate color powder coatings, while critical infrastructure projects require tamper-evident locking pins or quick-release clamps. Advanced manufacturing processes, such as CNC machining and automated plating lines, allow precise fulfillment of technical drawings for even low-volume orders. This approach minimizes on-site modifications, reduces installation errors, and ensures regulatory compliance. Over 60% of major contractors confirm their preference for custom fittings to optimize site efficiency and safety.

Case Study: Temporary Fence Fittings in Action Across Industries

The adaptability and performance of quality temporary fence fittings are perhaps best illustrated through real-world applications. One urban rail expansion project in Melbourne used over 25,000 fittings across two kilometers of perimeter fence, achieving a 38% reduction in site trespass incidents compared to standard solutions. At a leading international sports event, custom-branded and rapid-assembly clamps enabled the safe and orderly movement of 85,000 spectators, slashing installation times from six to just two hours. In the agricultural sector, specially galvanized couplers protected livestock over a three-month flood season by preventing corrosion and fence failure. These cases highlight how industry leaders leverage advanced fittings not only for security—but for operational efficiency, brand consistency, and peace of mind.

Obtaining Accurate Temporary Fence Fittings Quotes and Cost Analysis

Navigating the landscape for competitive temporary fence fittings quotes requires clear communication and a thorough understanding of project specifications. Pricing structures typically hinge on factors such as material choice, batch size, surface treatment, and logistics. Recent surveys indicate average bulk purchasing costs between $1.35–$2.10 per unit, with potential savings on orders exceeding 10,000 units. Many suppliers now offer digital quote configurators for instant cost break-downs, integrating volume discounts and real-time freight calculations. Transparency in quotations—itemized by fastening strength, anti-corrosion ratings, and compliance testing—empowers buyers to perform true apples-to-apples comparisons. For procurement teams, this means less risk and greater budget control over both upfront outlays and long-term maintenance.

Conclusion: Choosing the Right Temporary Fence Fittings for Your Project

The significance of selecting the appropriate temporary fence fittings cannot be overstated: from site safety to regulatory adherence, these components underpin the security and functionality of the entire perimeter system. Decision-makers must weigh technical strengths, track record of factories and suppliers, customization options, and data-driven application cases—while always seeking clear, competitive quotes. By keeping abreast of evolving material science and market trends, buyers ensure every temporary fencing solution offers maximum value today and resilience for tomorrow’s challenges. Prioritizing quality fittings from proven manufacturers is a strategic investment in safeguarding assets, people, and brand reputation throughout any temporary enclosure project.

(temporary fence fittings)

FAQS on temporary fence fittings

Q: What are temporary fence fittings?

A: Temporary fence fittings are components such as clamps, brackets, and couplers used to assemble and secure temporary fencing panels. They ensure stability and safety for short-term fencing needs.Q: How can I find a reliable temporary fence fittings factory?

A: Look for factories with proven experience, quality certifications, and positive customer reviews. Visiting their production sites or requesting product samples also helps ensure reliability.Q: What should I consider when choosing temporary fence fittings suppliers?

A: Consider supplier reputation, product quality, pricing, and delivery timelines. It’s also important to check if they offer after-sales support and customization options.Q: How can I get accurate temporary fence fittings quotes?

A: Provide detailed information about your requirements, such as quantity, specifications, and delivery location. Most suppliers will send a formal quote based on your needs.Q: Do temporary fence fittings factories offer customization services?

A: Yes, many factories offer customized fittings based on your project specifications. You can request adjustments in material, size, or coating to meet unique requirements.-

Temporary Fence Business for Sale Factory Direct Suppliers & Best Quotes

NewsJul.06,2025

-

High-Quality Temporary Fence Fittings - Trusted Factory & Suppliers Get Quick Quotes

NewsJul.06,2025

-

High Quality 358 Fence High Security Fence Manufacturer Anti-Climb & Durable Solutions

NewsJul.06,2025

-

High-Quality Industrial Security Fence Solutions Reliable Factory & Suppliers

NewsJul.05,2025

-

High Quality Temporary Fence Austrilian Direct Factory & Reliable Suppliers Quotes

NewsJul.05,2025

-

High Quality Chain Link Fence Temporary Fence Manufacturer & Wire Fence Supplier Pricelist

NewsJul.05,2025