آگوست . 24, 2025 01:40 Back to list

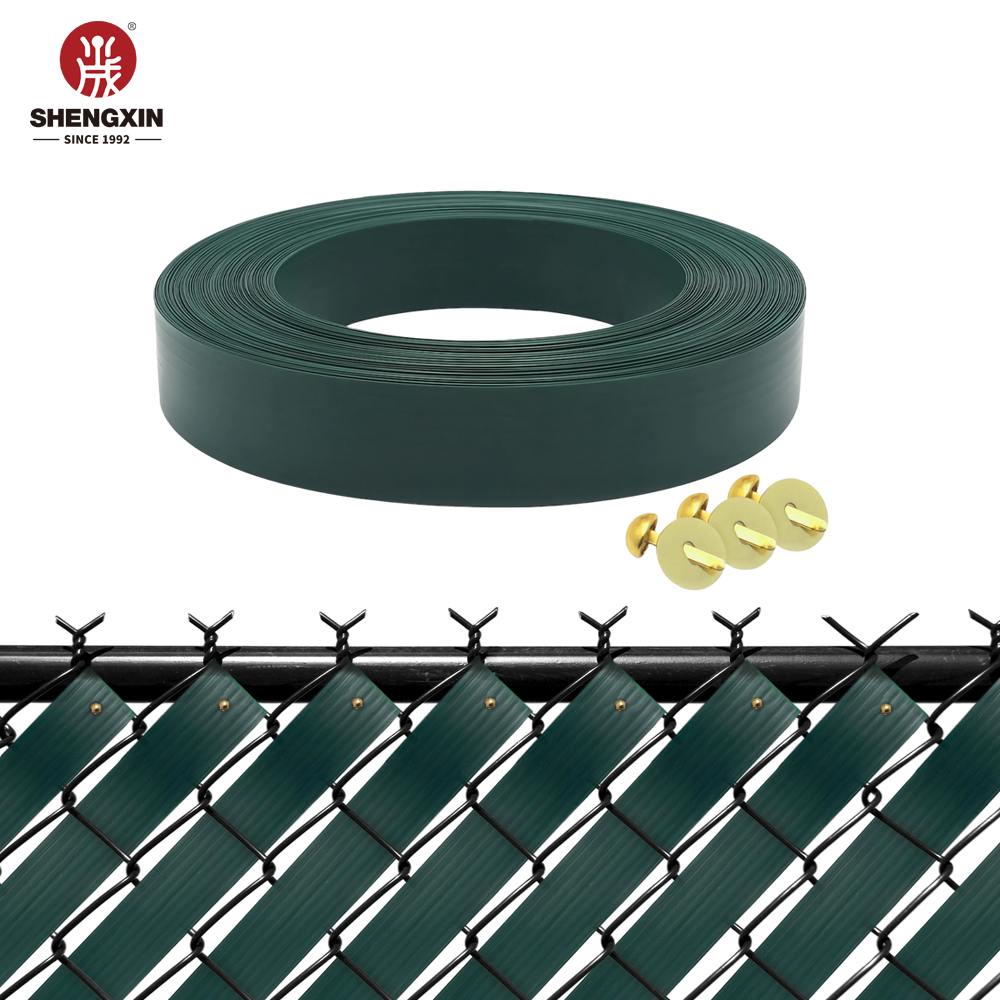

Durable 100% PVC Privacy Panels & Slats for Chain Link Fences

In the realm of perimeter security and aesthetic enhancement, 100% Pvc Panels Chain Link Fence Privacy Slats have emerged as a superior solution, offering an optimal blend of durability, privacy, and visual appeal for a diverse array of applications. Designed to integrate seamlessly with existing chain link fence structures, these slats provide an immediate upgrade, transforming open boundaries into private, secure, and visually pleasing enclosures. This comprehensive article delves into the technical intricacies, market dynamics, and operational advantages of these advanced privacy solutions, catering specifically to B2B decision-makers and engineering professionals seeking robust, long-term investments in infrastructure.

Industry Trends and Market Dynamics

The global market for fencing and security solutions is experiencing consistent growth, driven by increasing demands for privacy, security, and low-maintenance alternatives in both commercial and residential sectors. Within this landscape, PVC-based privacy solutions are gaining significant traction due to their inherent advantages over traditional materials. According to recent industry analyses, the demand for privacy fencing, particularly polymer-based options, is projected to grow at a Compound Annual Growth Rate (CAGR) of over 5% through 2028, fueled by urban development, industrial expansion, and heightened environmental awareness advocating for sustainable, recyclable materials. The shift towards aesthetically pleasing and eco-friendly options positions 100% Pvc Panels Chain Link Fence Privacy Slats at the forefront of this evolution, offering a compelling value proposition that balances performance with environmental responsibility. This trend is further amplified by the desire for quick installation and minimal ongoing operational costs, attributes intrinsically linked to high-quality PVC slat systems.

Key drivers include:

- Increased Privacy Needs: Urbanization and denser populations necessitate enhanced privacy for commercial properties, public facilities, and residential complexes.

- Durability and Low Maintenance: Businesses seek solutions that minimize long-term operational expenses associated with maintenance, painting, or replacement.

- Aesthetic Versatility: The ability to choose from various colors and styles allows for integration with architectural designs and branding requirements.

- Environmental Considerations: Recyclable PVC materials contribute to sustainability goals, an increasingly important factor for corporate social responsibility (CSR) initiatives.

Manufacturing Process Flow of PVC Privacy Slats

The production of high-quality 100% Pvc Panels Chain Link Fence Privacy Slats is a meticulously controlled process, ensuring product integrity, consistent performance, and extended service life. Adherence to international standards like ISO 9001 for quality management is paramount at every stage.

1. Material Selection and Compounding:

- Primary Material: Only virgin polyvinyl chloride (PVC) resin is utilized, ensuring optimal structural integrity and purity. Recycled content can compromise UV resistance and impact strength.

- Additives: Critical additives are blended with the PVC resin. These include:

- UV Inhibitors: High-grade titanium dioxide (TiO2) and hindered amine light stabilizers (HALS) are incorporated to provide superior resistance against degradation from solar radiation, preventing color fading, chalking, and brittleness. This ensures a service life often exceeding 25 years.

- Impact Modifiers: Acrylic or chlorinated polyethylene (CPE) modifiers enhance the slat's resistance to impact and shattering, crucial for outdoor applications in varying climates.

- Pigments: UV-stable pigments are added to achieve a wide range of consistent, long-lasting colors.

- Heat Stabilizers: To prevent degradation during processing and extend product longevity.

2. Extrusion Process:

- Feeding: The precisely compounded PVC mixture is fed into an industrial extruder.

- Melting and Shaping: Inside the extruder, the material is heated to a molten state and uniformly pushed through a die. This die is engineered to create the specific slat profile – typically flat, winged, or tubular – ensuring uniform thickness and structural integrity. The precise control of temperature and pressure is critical to prevent material degradation and ensure a smooth, defect-free surface finish.

- Cooling: The hot, extruded profile is then passed through a calibrated cooling bath (usually water-based) to solidify the material rapidly, maintaining its shape and minimizing shrinkage or warping.

3. Cutting and Finishing:

- Automated Cutting: Once cooled, the continuous PVC profile is precisely cut to specific lengths using automated precision cutting equipment. These lengths are typically standardized to common chain link fence heights (e.g., 4 ft, 5 ft, 6 ft, 8 ft, 10 ft), with custom lengths available upon request.

- Edge Treatment: Edges are typically clean-cut, and some designs may incorporate chamfered or rounded edges for easier installation and improved safety.

4. Quality Control and Testing:

- Dimensional Accuracy: Regular checks ensure adherence to specified length, width, and thickness tolerances, often to ASTM F668 standards for PVC coated chain-link fence fabric.

- Color Consistency: Spectrophotometric analysis verifies color uniformity across batches and against master samples.

- Impact Resistance: Samples undergo impact testing (e.g., Izod or Charpy impact tests) to confirm their ability to withstand physical stress.

- UV Weathering Tests: Accelerated weathering tests (e.g., QUV or Xenon Arc testing per ASTM G154 or G155) simulate prolonged exposure to sunlight and environmental conditions to validate the effectiveness of UV inhibitors. Products are typically tested to ensure color retention (Delta E values within acceptable limits) and mechanical property retention after thousands of hours of exposure.

- Material Composition Analysis: Fourier-transform infrared spectroscopy (FTIR) or other analytical methods confirm the PVC composition and presence of essential additives.

Target Industries and Advantages:

Target Industries: Petrochemical, Metallurgy, Water Supply & Drainage, Commercial Landscaping, Public Utilities, Sports Facilities, Data Centers, Residential Communities, Educational Institutions.

Typical Advantages: Outstanding corrosion resistance, especially in harsh industrial or coastal environments, eliminating the need for painting or rust treatment. Exceptional UV stability reduces long-term degradation and maintains aesthetic appeal. The product's low maintenance attributes contribute to significant operational energy saving by reducing labor and material costs associated with upkeep compared to wood or metal alternatives. Enhanced privacy and security are immediate benefits, coupled with noise reduction properties in specific applications.

Technical Specifications

Understanding the precise technical parameters of 100% Pvc Panels Chain Link Fence Privacy Slats is crucial for ensuring compatibility, performance, and compliance with project requirements. The following table outlines typical specifications based on industry standards and product offerings:

Product Specification Table: PVC Privacy Slats

| Parameter | Specification | Relevant Standard/Note |

|---|---|---|

| Material Composition | 100% Virgin High-Density PVC | Ensures optimal durability & color stability. |

| UV Resistance | High-grade UV inhibitors (e.g., TiO2, HALS) | ASTM G154/G155 (Accelerated Weathering) compliant. Excellent color retention & material integrity. |

| Temperature Range | -40°C to +80°C (-40°F to +176°F) | Resistant to extreme weather conditions without cracking or warping. |

| Privacy Factor | 75% to 98% (depending on slat type/weave) | Visual obstruction provided by the installed slats. |

| Available Heights | 4 ft (1.2m), 5 ft (1.5m), 6 ft (1.8m), 8 ft (2.4m), 10 ft (3.0m) | Custom heights available. |

| Thickness | Typically 0.05" - 0.07" (1.2mm - 1.8mm) | Varies by profile (e.g., flat, tubular, winged). |

| Wind Load Resistance | Engineered for standard fence gauges (9 & 11 gauge) | Installation significantly increases wind resistance of chain link fences. Refer to local building codes. |

| Warranty | Typically 10-25 years against fading, cracking, and manufacturing defects | Manufacturer dependent, confirms product longevity. |

Application Scenarios

The versatility and robust characteristics of 100% Pvc Panels Chain Link Fence Privacy Slats make them ideal for a broad spectrum of applications where enhanced privacy, security, and aesthetics are required. From industrial complexes to residential perimeters, these slats offer a practical and efficient solution.

- Commercial Properties: Retail centers, office parks, and corporate campuses often require visual barriers for service areas, waste enclosures, or to segment different operational zones. PVC slats provide an economical yet professional-looking privacy solution that withstands heavy traffic and varying environmental conditions.

- Industrial Facilities: Petrochemical plants, manufacturing sites, and utility substations utilize these slats for obscuring sensitive equipment, providing visual security for restricted areas, and mitigating dust or debris transfer. Their corrosion resistance is particularly beneficial in aggressive industrial atmospheres.

- Public Sector and Utilities: Water treatment facilities, power substations, and telecommunication sites benefit from the added layer of privacy and security, preventing unauthorized visual access and enhancing public safety.

- Sports and Recreation: Around tennis courts, swimming pools, or baseball fields, PVC slats offer privacy, act as windbreaks, and can help contain sports balls. They also provide an aesthetically pleasing backdrop for these facilities.

- Educational Institutions: Schools and universities employ privacy slats for securing playgrounds, segregating different campus areas, and enhancing safety around sensitive zones.

- Temporary Site Management: For construction sites or event venues, privacy slats offer a quick-to-install, temporary solution for site containment, visual screening, and security.

Technical Advantages and Performance Metrics

The superior engineering and material composition of 100% Pvc Panels Chain Link Fence Privacy Slats confer a range of technical advantages that translate directly into long-term value and performance for B2B clients.

- Exceptional Durability and Longevity: Manufactured from virgin PVC with robust UV inhibitors and impact modifiers, these slats resist fading, cracking, chalking, and warping, even under harsh environmental conditions. Their projected service life often exceeds 25 years, significantly outperforming wood, fabric, or lower-grade plastic alternatives.

- Superior Corrosion Resistance: Unlike metal fences, PVC is inherently resistant to rust, corrosion, and chemical degradation. This makes them ideal for coastal areas, industrial zones with chemical exposure, or environments with high humidity and precipitation, drastically reducing maintenance costs.

- Low Maintenance Requirements: PVC slats require no painting, staining, or sealing. Routine cleaning typically only involves a simple hose down, leading to significant labor and material cost savings over the product's lifespan. This contributes to a lower total cost of ownership (TCO).

- Enhanced Aesthetic Appeal: Available in a wide palette of fade-resistant colors and various profiles (e.g., winged, flat, tubular), these slats can complement any architectural style, improving the visual impact of a property while providing privacy.

- Easy and Rapid Installation: Designed for seamless integration, the slats typically slide vertically into the chain link mesh. This straightforward installation process minimizes labor time and costs, allowing for quicker project completion.

- Wind Load Performance: While increasing the surface area, quality PVC slats are engineered to integrate securely within the chain link fabric. Manufacturers provide guidelines and sometimes test data regarding the impact on wind load resistance, ensuring structural integrity when properly installed on appropriate fence gauges.

- Environmental Responsibility: PVC materials are recyclable, supporting sustainable practices. The long lifespan also reduces waste by minimizing the frequency of replacement.

Vendor Comparison: Critical Selection Criteria

When selecting a supplier for 100% Pvc Panels Chain Link Fence Privacy Slats, B2B purchasers must evaluate vendors based on stringent criteria that extend beyond initial cost. A comprehensive assessment ensures optimal product performance, reliability, and long-term support.

Comparison Table: PVC Slats vs. Alternative Privacy Solutions

| Feature | PVC Privacy Slats | Aluminum Slats | Fabric/Mesh Screens | Wood Panels |

|---|---|---|---|---|

| Material Longevity | Excellent (25+ years) | Excellent (30+ years, if coated) | Fair (3-7 years) | Good (10-20 years, with maintenance) |

| UV Resistance | Excellent (fade, chalk, crack resistant) | Good (paint/coating dependent) | Poor to Fair (fades, degrades) | Fair (fades, weathers) |

| Corrosion Resistance | Excellent (no rust, chemical inert) | Excellent (naturally resistant) | N/A (no metal) | Poor (rot, decay susceptible) |

| Maintenance | Very Low (occasional rinse) | Low (occasional cleaning) | Moderate (cleaning, frequent replacement) | High (painting, staining, repairs) |

| Cost (Initial) | Moderate | High | Low | Moderate |

| Total Cost of Ownership (TCO) | Low | Moderate | High (due to replacement) | Moderate to High (due to maintenance) |

Key vendor evaluation points should include:

- Material Quality: Insist on 100% virgin PVC with specified UV inhibitors. Request material safety data sheets (MSDS) and technical specifications.

- Certifications: Verify ISO 9001 certification for manufacturing quality and adherence to relevant ASTM standards (e.g., for UV stability, impact resistance).

- Warranty & Support: A robust warranty (10-25 years) indicates confidence in product longevity. Evaluate after-sales support, technical assistance, and lead times.

- Customization Capabilities: Assess the ability to provide custom lengths, colors, and profiles to match unique project specifications.

- Track Record: Look for vendors with extensive experience, positive customer feedback, and a portfolio of successful B2B projects. Longevity in the market (e.g., 20+ years of service) often correlates with reliability.

Customized Solutions

Recognizing that every B2B project presents unique challenges, manufacturers of 100% Pvc Panels Chain Link Fence Privacy Slats offer extensive customization options to meet specific client requirements. This flexibility is crucial for achieving optimal functionality, aesthetics, and compliance.

- Custom Lengths: While standard heights are available, slats can be precisely cut to match non-standard fence heights, minimizing waste and ensuring a perfect fit. This is particularly valuable for unique architectural designs or uneven terrain.

- Color Matching: Beyond standard color palettes, custom color matching services are often available to align with specific corporate branding guidelines, building facades, or landscape designs. This involves advanced spectrophotometry to ensure accurate and consistent color reproduction.

- Profile Variations: Different slat profiles (e.g., winged, flat, tubular, angled) offer varying levels of privacy and aesthetic effects. Custom profiles can be engineered for specialized applications requiring specific wind resistance, visual obstruction, or unique architectural features.

- Accessory Integration: Manufacturers can provide tailored accessory packages, including bottom locking channels, top caps, or specialized fasteners, to enhance stability, security, and ease of installation for specific fence types.

- Project Consultation and Design: Reputable vendors offer expert consultation to assist with material selection, design optimization, and technical specifications, ensuring the customized solution fully addresses the project's complex needs.

Application Case Studies

Case Study 1: Perimeter Security for a Data Center

Client: Global Tech Solutions, a leading data center operator.

Challenge: The client required an immediate upgrade to the existing chain link fence perimeter of their new data center facility. The primary objectives were to enhance visual privacy for sensitive infrastructure, deter unauthorized visual surveillance, and improve the overall aesthetic without compromising security or necessitating a complete fence overhaul.

Solution: We supplied 5,000 linear feet of 8-foot-high, dark gray 100% Pvc Panels Chain Link Fence Privacy Slats (winged profile, 98% privacy factor) specifically designed for 9-gauge chain link mesh. The slats were manufactured with enhanced UV stabilizers and impact modifiers to ensure long-term durability in a challenging climate.

Results: The installation, completed by the client's preferred contractor in less than a week, provided an immediate and significant increase in visual privacy. The dark gray color integrated seamlessly with the modern architecture of the data center. The PVC slats eliminated the need for costly repainting or rust treatment, projecting a maintenance cost saving of over 70% compared to previous metal screen solutions over a 10-year period. The enhanced visual barrier also contributed to the facility's compliance with ISO 27001 physical security standards.

Case Study 2: Noise and Visual Barrier for a Municipal Water Treatment Plant

Client: City of Evergreen Public Works Department.

Challenge: The municipal water treatment plant, located near a growing residential area, faced complaints regarding noise from operational equipment and desired to create a more visually appealing and private boundary. The environment also presented challenges with high humidity and potential chemical exposure from the plant's processes, requiring a highly durable and corrosion-resistant solution.

Solution: We recommended and supplied 3,500 linear feet of 10-foot-high, forest green 100% Pvc Panels Chain Link Fence Privacy Slats (flat tubular profile, 90% privacy factor). The green color was chosen to blend with the surrounding natural landscape. Our technical team provided guidance on installation to maximize acoustic dampening and wind load performance for the specific fence gauge.

Results: The PVC slats successfully reduced ambient noise levels emanating from the plant by an estimated 5-7 dB, improving neighborhood relations. The corrosion-resistant nature of the PVC proved ideal for the humid and chemically rich environment, demonstrating no signs of degradation after two years of service, where traditional materials would have corroded rapidly. The aesthetic improvement was immediately noticeable, transforming the industrial boundary into a more harmonious part of the community.

Frequently Asked Questions (FAQ)

Q1: Are the PVC privacy slats truly 100% opaque?

A: While achieving 100% opacity is challenging for any material, our 100% Pvc Panels Chain Link Fence Privacy Slats offer privacy factors ranging from 75% to 98%, depending on the specific slat profile and weave density. For maximum visual obstruction, we recommend our winged or tubular profiles which are designed to interlock tightly, significantly reducing visibility through the fence mesh.

Q2: How do these slats perform in high-wind environments?

A: The installation of privacy slats significantly increases the surface area of a chain link fence, thereby increasing its susceptibility to wind loads. Our slats are designed to be robust, and when properly installed on an adequately gauged chain link fence (e.g., 9-gauge or heavier, with appropriate post and footing specifications), they can withstand substantial wind forces. We advise consulting local building codes and structural engineers for projects in extreme wind zones.

Q3: What is the expected lead time for large orders?

A: Our standard lead time for typical bulk orders (e.g., up to 10,000 linear feet) is generally 2-4 weeks from order confirmation, subject to current production schedules and material availability. For customized solutions or exceptionally large volumes, we provide a project-specific lead time. We maintain robust inventory levels of popular colors and sizes to facilitate quicker fulfillment for urgent requirements. Please contact our sales team for precise lead time estimates for your specific project.

Q4: What warranty is provided with your PVC privacy slats?

A: We stand behind the quality of our products with a comprehensive 25-year limited warranty against manufacturing defects, excessive fading (beyond standard weathering within acceptable Delta E values), cracking, chalking, or warping under normal usage conditions. Our commitment reflects the superior material science and manufacturing processes applied to our 100% Pvc Panels Chain Link Fence Privacy Slats. Full warranty details are available upon request.

Q5: Do you offer installation services or technical support for installation?

A: While we do not typically provide direct installation services, we offer extensive technical support and detailed installation guides to our B2B clients and their chosen contractors. Our engineering team can provide consultation on best practices, wind load considerations, and specific project challenges to ensure successful and efficient installation. We can also recommend certified installers in various regions through our partner network.

Conclusion

The integration of 100% Pvc Panels Chain Link Fence Privacy Slats represents a strategic investment for any B2B entity seeking a high-performance, aesthetically pleasing, and cost-effective perimeter solution. Their inherent resistance to environmental degradation, combined with minimal maintenance requirements and a long operational lifespan, translates into a superior total cost of ownership compared to traditional alternatives. By focusing on stringent material quality, advanced manufacturing processes, and comprehensive technical support, these PVC privacy slats stand as a testament to innovation in perimeter security, providing unparalleled privacy, durability, and visual enhancement for a wide array of industrial, commercial, and public sector applications.

Authoritative References

- ASTM International. "ASTM F668 - 18 Standard Specification for Poly(Vinyl Chloride) (PVC) and Other Organic Polymer-Coated Steel Chain-Link Fence Fabric."

- ASTM International. "ASTM G154 - 16 Standard Practice for Operating Fluorescent Ultraviolet (UV) Lamp Apparatus for Exposure of Nonmetallic Materials."

- ISO. "ISO 9001:2015 - Quality management systems — Requirements."

- The Vinyl Institute. "The Environmental Impact of PVC: A Lifecycle Approach."

- Fredericks, John. "Polyvinyl Chloride (PVC)." Plastics Design Handbook. McGraw-Hill Education, 2017.

This is the last article

-

Durable 100% PVC Privacy Panels & Slats for Chain Link Fences

NewsAug.24,2025

-

Premium Galvanized Steel Fence Designs - Durable & Secure Panels

NewsAug.23,2025

-

ODM 7' Security Fence | 358 Anti-Climb Galvanized Panels

NewsAug.22,2025

-

3D Welded Wire Mesh Fence Panels with Peach Posts

NewsAug.21,2025

-

Australia Farm Fence Black Star Picket Y Post - Durable Metal Cattle Post

NewsAug.19,2025

-

Metal Covers - Anping County Shengxin | Durability, Corrosion-Resistant

NewsAug.18,2025