Նյմ . 06, 2024 15:14 Back to list

Manufacturers of Anti-Climb Fence Panels for Enhanced Security Solutions

The Manufacturing of Anti-Climb Fence Panels A Comprehensive Overview

In today’s world, security has become a paramount concern for both residential and commercial properties. One effective way to enhance safety measures is through the installation of anti-climb fence panels. These structures are designed to deter intruders, providing a physical barrier that is both strong and difficult to scale. This article delves into the manufacturing process of anti-climb fence panels, exploring the factors that contribute to their effectiveness, as well as the various types available in the market.

Understanding Anti-Climb Fence Panels

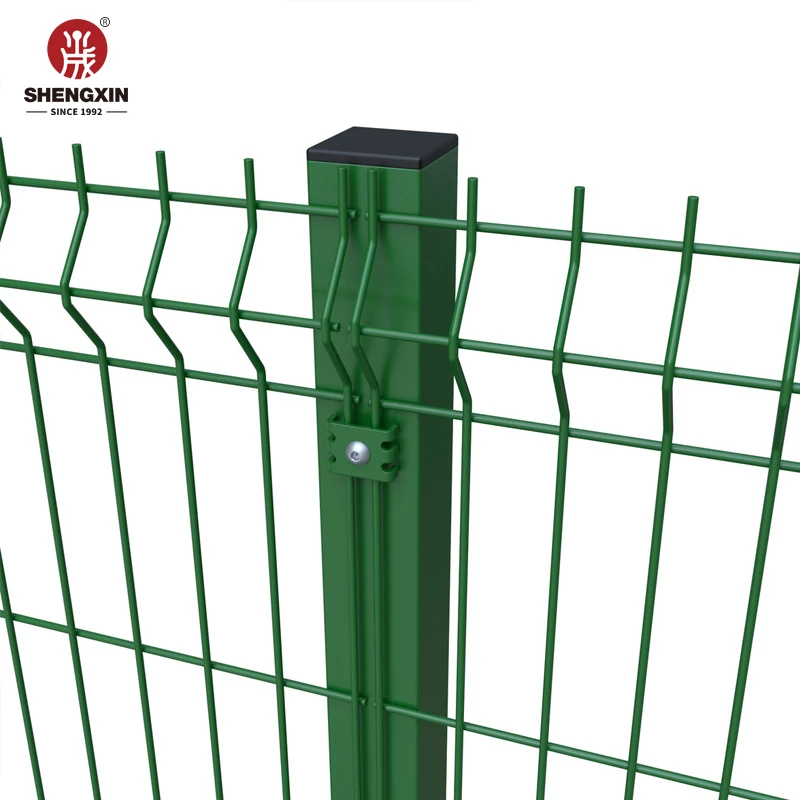

Anti-climb fence panels are specifically engineered to prevent unauthorized access. Unlike standard fencing, which may easily be scaled, these panels incorporate various design elements that thwart climbing attempts. Features such as spikes, sharp edges, and closely spaced vertical bars enhance their security capabilities. The materials used in their construction, typically galvanized steel or robust aluminum, add to their durability and resistance against wear and tear.

Key Manufacturing Processes

1. Material Selection The first step in the manufacturing process involves selecting the appropriate materials. High-quality steel or aluminum is preferred due to its strength and resilience. Galvanization is often employed to prevent rust and corrosion, thereby extending the lifespan of the fence panels.

2. Design and Engineering Once the materials are secured, the design phase begins. Engineers utilize computer-aided design (CAD) software to create precise specifications for the anti-climb features. This may include the spacing of bars, the height of the panels, and the incorporation of anti-climb spikes or meshes.

3. Cutting and Shaping The next stage involves cutting the raw materials into specified lengths and shapes. This is typically accomplished using laser cutting technology, which ensures accuracy and minimizes waste. The pieces are then shaped and assembled as per the designs.

4. Welding and Joining After cutting, the components are welded or otherwise joined together to form a cohesive structure. Skilled welders ensure that the joints are strong and secure, which is crucial for maintaining the integrity of the fence.

anti climb fence panels factories

5. Finishing Treatments To enhance appearance and further protect against environmental elements, the panels undergo finishing treatments. This includes powder coating or painting, which not only adds color but also acts as an additional barrier against corrosion and rust.

6. Quality Control Before the panels are shipped out, they undergo rigorous quality control testing. This includes stress tests to ensure they can withstand force and environmental conditions. Panels that do not meet the necessary standards are either reworked or discarded.

Market Variations

The demand for anti-climb fence panels has led to various product variations on the market. Some of the most popular types include

- Welded Wire Fencing This type features tightly woven wires that make climbing almost impossible. Available in various heights and mesh sizes, it is often utilized around commercial properties and schools.

- Palisade Fencing Known for its formidable appearance, palisade fencing is characterized by vertical steel pales that are spaced closely together. The pointed tops deter climbing, making it an ideal choice for industrial applications.

- Decorative Security Fencing Combining aesthetics with security, these panels offer an appealing look without compromising on safety. They often feature ornamental designs while incorporating anti-climb elements.

Conclusion

The manufacturing of anti-climb fence panels is a complex process that combines engineering, skilled craftsmanship, and rigorous quality control. As the need for security grows, these innovative fencing solutions provide an effective way to protect properties from unauthorized access. By understanding the manufacturing processes and recognizing the variety of options available, consumers can make informed choices that best suit their security needs. Whether for residential, commercial, or industrial applications, investing in high-quality anti-climb fence panels is a proactive step toward ensuring safety and peace of mind.

-

Durable Chain Link Temporary Fence | Quick Setup & Security

NewsAug.05,2025

-

Coated Galvanized Steel Wire Mesh Fencing Panels | Durability & Protection

NewsAug.04,2025

-

Powder Coated Double Wire Mesh Fence-Anping County Shengxin Metal Products Co., Ltd

NewsAug.03,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd

NewsAug.03,2025

-

Power Coated 358 Anti Climb Mesh Fence for Airports

NewsAug.03,2025

-

Powder Coated Double Wire Mesh Fence-Anping County Shengxin Metal Products Co., Ltd.

NewsAug.02,2025