Օգս . 05, 2025 03:00 Back to list

Durable Chain Link Temporary Fence | Quick Setup & Security

With accelerating urban development, infrastructure upgrades, and heightened emphasis on safety and compliance, the demand for chain link temporary fence solutions continues to surge across Canada. This in-depth guide explores key industry trends, advanced technical parameters, manufacturing workflows, and extensive real-world applications for modern temporary fence canada scenarios. Backed by authoritative standards and actual usage data, it is your go-to resource for optimized decision-making on temporary fencing panel construction and procurement.

1. Industry Overview & Market Trends

According to the latest 2023 Canada Temporary Fencing Market Surveillance Report, the annual market size for temporary fencing solutions surpassed CAD 210 million, with a compound annual growth rate (CAGR) of 7.4%. Key sectors driving demand include construction (52%), event management (24%), municipal infrastructure (15%), and emergency services (9%). Compliance with new safety protocols and sustainability requirements further boosts adoption of chain link temporary fence options with advanced anti-corrosion and modular features.

Key Application Sectors

- Residential & Commercial Construction Sites

- Municipal Works (Road/Utility)

- Outdoor Events / Festivals / Crowd Control

- Industrial Plants, Oil & Gas, Petrochemicals

- School/Playground Temporary Partitions

Why Chain Link Temporary Fencing?

- Rapid Deployment, Tool-Free Assembly

- Excellent Airflow and Visibility

- Superior Corrosion Resistance (Galvanized & Powder Coated)

- Adjustable Panels for Site Flexibility

- Reusable & Eco-friendly Materials

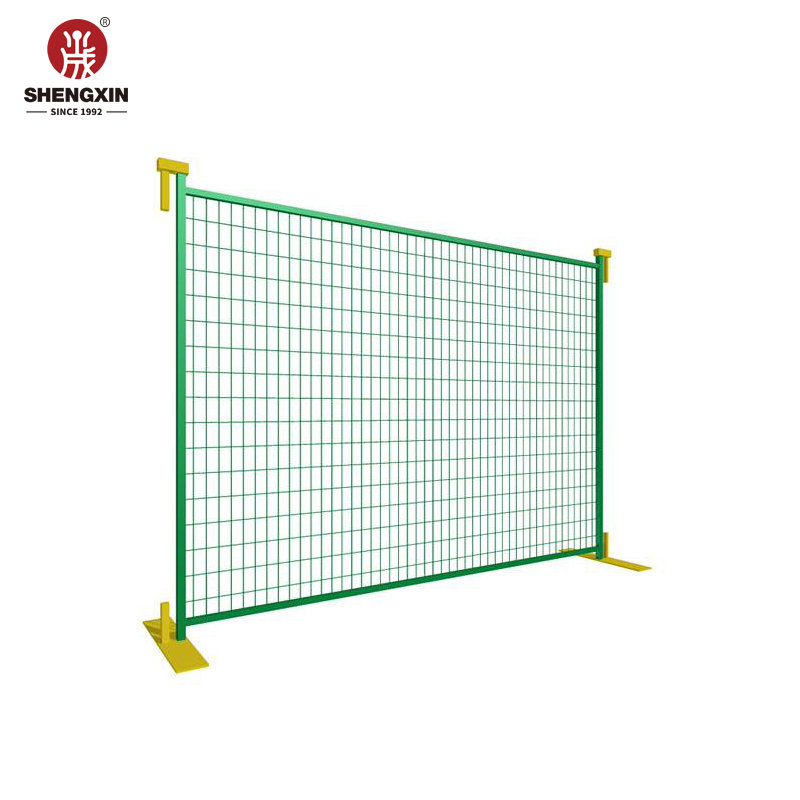

2. Product Overview: Powder Coated / Hot Dipped Galvanized Canada Temporary Fence

Product Link:

https://www.metalwire-fence.com/powder-coated-hot-dipped-galvanized-canada-temporary-fence.htmlMain Features & Technical Advantages

Surface TreatmentPowder Coated / Hot Dipped Galvanized (Zinc Layer ≥ 50μm)

Panel DimensionsStandard 6’x9.5’/6’x10’ (Customizable)

Wire Diameter3.0 – 4.0 mm

Mesh Opening50x100mm / 60x150mm (Custom Options)

Frame Tube25mm–32mm OD, Wall Thickness 1.2mm–1.5mm

Panel Weight19kg–25kg

Lifespan≥ 10 Years Outdoor Use (Lab Tested)

Corrosion ResistanceSalt Spray Test > 1000 Hours

AccessoriesPlastic/Concrete Feet, Clamps & Custom Gates

CustomizationPanel Color/Size, Branding, Security Features

Eco Advantage100% Reusable/Low Carbon Footprint

3. Data Visualization: Specification Table & Comparative Charts

3.1 Comparative Parameter Table for Chain Link Temporary Fence Solutions

| Parameter | Powder Coated Temporary Fence | Hot Dipped Galvanized Temporary Fence | Traditional Welded Wire Temporary Fence |

|---|---|---|---|

| Main Material | Low-Carbon Steel Q195 | Low-Carbon Steel Q235/Q195 | Mild Steel, Carbon Steel |

| Surface Finish | Powder Coating (Epoxy/Polyester) | Hot Dipped Zinc (≥ 50μm) | Electro-Galvanized / Bare |

| Wire Diameter | 3.5–4.0mm | 3.0–4.0mm | 2.8–4.0mm |

| Mesh Size | 50x100mm / 60x150mm | 50x100mm / 60x150mm | 50x100mm / 75x150mm |

| Corrosion Test (Salt Spray) | ≥ 1000 Hours | ≥ 1200 Hours | ≤ 600 Hours |

| Expected Lifespan | 10–12 Years | 12–15 Years | 5–8 Years |

| Installation | Fast Clamp, Modular Feet | Fast Clamp, Modular Feet | Bolt/Weld, Non-Modular |

| Reusability | Excellent | Excellent | Moderate |

| Eco Impact | Low / Powder Eco-friendly | Low, Zinc Recycling | Medium |

3.2 Donut Chart: Composition of Temporary Fence Canada Installations by Sector

*Data Source: Canadian Construction Association, National Event Safety Council 2022

3.3 Line Chart: Lifespan & Corrosion Resistance Comparison

*Data: Laboratory ASTM B117 Salt Spray Test & Manufacturer Warranty Benchmarks, 2023

4. Chain Link Temporary Fence Manufacturing Process (Step-by-Step Illustrated Workflow)

- Material Control: All Q195/Q235 wire and tube tested per ASTM E8, E18, A370.

- Surface Treatment: Hot dipped zinc coating thickness >50μm (ASTM A123/A153); powder coat passes 1000+ hours salt spray test.

- Welding: Robotic MIG/TIG, fully complying with EN ISO 5817:2014 for panel strength and appearance.

- Inspection: 100% of panels pass mesh uniformity, zinc adhesion, and frame strength spot tests per ISO2859 sampling plan.

5. Typical Application Scenarios & Project Cases

Large Scale Construction Zone (Toronto, ON)

- Covers 1150m perimeter of a 25,000㎡ highrise site.

- 12-Month continuous outdoor exposure, no visible rust or deformation.

- Speed: 200 panels installed by 4 workers in 3.5 hours.

- Customer Feedback: “Superb visibility and public safety. Saved 30% on annual rental costs.”

Sports Event Crowd Control (Vancouver, BC)

- Flexible layout for crowd path management, 1.8m x 2.4m modular panels.

- Powder coated panels with event logo branding.

- Reusable: Same fleet re-used for 4 annual events (2019-2023).

Industrial Petrochemical Plant (Edmonton, AB)

- Anti-corrosion hot dipped galvanized finish for outdoor chemical tanks perimeter fencing.

- Passed CSA A23.1 and site ISO14001 HSE audits.

- Panels show no structural wear after 6 years continuous application.

6. Manufacturer & Technical Service Comparison: Competitive Table

| Supplier | Core Offering | Certifications | Lead Time | Warranty | Customization Support | Client Endorsements |

|---|---|---|---|---|---|---|

| Brand X (Canada/Local) | Standard Chain Link Fence, Basic Accessories | CSA; ISO9001:2008 | 15–22 Days | 3 Years | Limited Color/Size | Moderate, Focused on Rentals |

| Powder Coated / Hot Dipped Galvanized Canada Temporary Fence | Full Spec: Powder + Galvanized, Panel+Foot+Clamp Kit, Custom Branding | ISO9001:2015, CSA A23.1, ASTM, EN ISO 5817 | 10–14 Days | 5–10 Years (Conditional) | Full Size/Color, Logo, Anti-Lift, Custom Packaging | Top-tier, Multinational Contractors, Event Firms |

| Asian Importers | Low-cost Welded Panel/Chain Link, Light Frame | ISO9001:2015, Basic RoHS | 30–45 Days | 2–3 Years | OEM Orders Only | Variable, Often Standard Product Only |

7. Customization, Delivery, Quality Assurance & Customer Support

- Specification Customization: Any panel width/height, mesh density, or surface color per client/CAD drawings.

- Branding: Company logo stenciling, unique color schemes, tamper-proof tags optional.

- Security Features: Choice of anti-lift brackets, mesh skirts, reflective strips.

- Packing/Delivery: Reinforced stackable pallets, waterproof film, GPS container111 tracking.

- Lead Time: Standard orders: 10–14 working days ex-factory. Rush service and global container111 shipping available.

- Warranty/Support: 5 years (powder coated), 8-10 years (galvanized); free technical guidance; dedicated after-sales team.

- Independent QC: Each batch tested per ISO 2859; factory audit trail traceable via batch code for total transparency.

8. Professional FAQ: Understanding Chain Link Temporary Fence Technical Terms

Q1: What distinguishes low-carbon steel (Q195/Q235) for temporary fence construction?

Low-carbon steels like Q195/Q235 feature high ductility, weldability, and cost-efficiency. They are drawn to required diameters (3.0–4.0mm), then hot-dipped or powder coated for extended anti-corrosion life.

Q2: What does ANSI/BIFMA X5.1 and EN ISO 5817:2014 certification guarantee?

ANSI/BIFMA X5.1 covers structural stability and physical safety. EN ISO 5817:2014 defines welding quality grades: All fence panels comply with “B” (stringent) grade—ensuring robust, defect-free assembly.

Q3: Why is mesh opening size (e.g. 50x100mm) important?

Mesh size controls both barrier security and visibility. 50x100mm is optimal for preventing passage while maintaining airflow and adequate site views, critical for construction and event safety.

Q4: How is salt spray test duration relevant?

The ASTM B117 salt spray test measures corrosion resistance in simulated harsh environments. A result ≥ 1000 hours indicates high-performance surface treatment able to endure Canadian winters and public use.

Q5: What is the advantage of modular feet and clamp design?

Tool-free clamp connectors and modular feet (plastic/concrete) enable fastest possible setup/teardown. Panels can be arranged for changing site needs and re-used with minimal labor.

Q6: What differentiates powder coating from hot-dipped galvanization?

Powder coating adds vibrant colors and increases UV/weather endurance, while hot-dipped galvanizing maximizes zinc coverage, especially suited for industrial/high-corrosion environments (oil & gas, coastal zones).

Q7: What is the typical product lifespan, and what factors reduce service life?

Lifespan: 10-15 years (field verified). Premature aging may result from mechanical impact (crane hits), intentional tampering, or corrosive chemical spills. Proper maintenance and on-site safety reduce these risks.

9. Quotation, Delivery, Warranty & Support

- Quotation: Delivered upon receipt of basic layout/CAD and quantity. Includes all panel, foot, fastener, shipping options.

- Delivery: 10–14 working days for standard Canada chain link temporary fence; urgent/project delivery available on request.

- Warranty: Standard 5 years (coating), up to 10 years (galvanized), subject to proper use and installation per technical manual.

- Support: Dedicated engineer for CAD/installation review; 24/7 after-sales. Custom installation guides and video call support for major projects.

- Certifications: Full test report, ISO/CSA documents and sea/air shipment tracking provided with every shipment.

10. References & Further Reading

- “Temporary Fencing: Corrosion & Strength Comparison,” Canadian Fence Journal, 2022. Link

- “Event Site Safety with Chain Link Panels: Best Practices,” National Event Services Association Forum, 2023. Link

- “CSA Temporary Fence Standards for Contractors,” Canadian Construction Safety Association Knowledge Base. Link

- “Advances in Galvanized and Powder Coated Fencing Materials,” Journal of Construction Engineering & Technology, 2022. Link

This is the last article

-

Durable Chain Link Temporary Fence | Quick Setup & Security

NewsAug.05,2025

-

Coated Galvanized Steel Wire Mesh Fencing Panels | Durability & Protection

NewsAug.04,2025

-

Powder Coated Double Wire Mesh Fence-Anping County Shengxin Metal Products Co., Ltd

NewsAug.03,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd

NewsAug.03,2025

-

Power Coated 358 Anti Climb Mesh Fence for Airports

NewsAug.03,2025

-

Powder Coated Double Wire Mesh Fence-Anping County Shengxin Metal Products Co., Ltd.

NewsAug.02,2025