Jul . 07, 2025 07:30 Back to list

High-Quality Chain Link Fence Parts Reliable Suppliers & Factory Prices

- Introduction to chain link fence part

and industry overview - Technical superiority: Materials, engineering, and performance

- Comparative analysis: Suppliers and factories overview

- Customization and design solutions

- Applications in residential, commercial, and industrial settings

- Market trends and cost efficiency: Comparative data insights

- Conclusion highlighting leading chain link fence part suppliers

(chain link fence part)

Chain Link Fence Part: Industry Overview and Importance

Chain link fencing stands as an irreplaceable solution for perimeter protection, demarcation, and security across various environments. At the center of these structures are the essential chain link fence part components, which support the integrity and longevity of the entire system. Globally, the fencing market crossed a value of USD 27.2 billion in 2023, with chain link segments representing over 35% of installations due to cost, flexibility, and ease of assembly.

The importance of quality in each fence part – including posts, fittings, mesh wire, tension bands, and gates – cannot be overstated. Subpar components shorten fence life cycles by up to 40%, increasing long-term costs and diminishing security. Selecting the right chain link fence part suppliers is therefore a critical operation, influencing not just material quality but installation efficiency, warranty, and after-sales support. According to the American Fence Association, a professionally specified chain link fence, assembled from premium-grade parts, can last 20–25 years with minimal maintenance, compared to 10–15 years for standard-grade equivalents.

Technical Superiority: Materials, Engineering, and Performance

Technical advancement in chain link fence part manufacturing has raised industry standards in galvanized coatings, alloy selection, and assembly methods. Today, wires with zinc-aluminum hybrid coatings offer corrosion resistance up to 350% greater than traditional pure zinc galvanization, ensuring durability even in harsh coastal or industrial environments.

In engineering terms, high-tensile steel wires featuring yield strengths above 550MPa demonstrate 25% greater mesh stability and reduced sag over time, which is integral in security-sensitive zones. Modern tension bands and post caps utilize UV-stabilized polymers or advanced alloys for a lifespan exceeding 20 years. Such innovations not only extend operational life but decrease routine service frequency by over 50%, minimizing management overheads for property owners.

Comparative Analysis: Suppliers and Factories Overview

When choosing between chain link fence part factory sources and independent suppliers, decision-makers must weigh factors like consistency, certifications, technical capabilities, and global reach. The best factories adhere to ISO 9001:2015, ASTM F668/F1043, and BS EN 10244-2 standards, guaranteeing dimensional serviceability and surface finish.

Below is a comparative table summarizing key metrics for leading international manufacturers and suppliers:

| Name | Certification | Annual Output (tons) | Customization | Export Regions |

|---|---|---|---|---|

| Alpha Fence Parts Co. | ISO 9001, ASTM | 48,000 | Yes (Bespoke) | North America, Europe, Asia |

| FencePro Manufacturing | ASTM, CE | 35,000 | Yes (Design/Logo) | Middle East, Africa |

| Global ChainLink Supply | ISO, BS EN | 50,000 | No | Oceania, S. America |

| Titan Wireworks | ISO, ASTM | 60,000 | Yes (Advanced) | Worldwide |

Data reveals that larger, fully-certified factories offer comprehensive customization and higher output, which directly benefits enterprises with unique requirements and tight deadlines.

Customization and Design Solutions

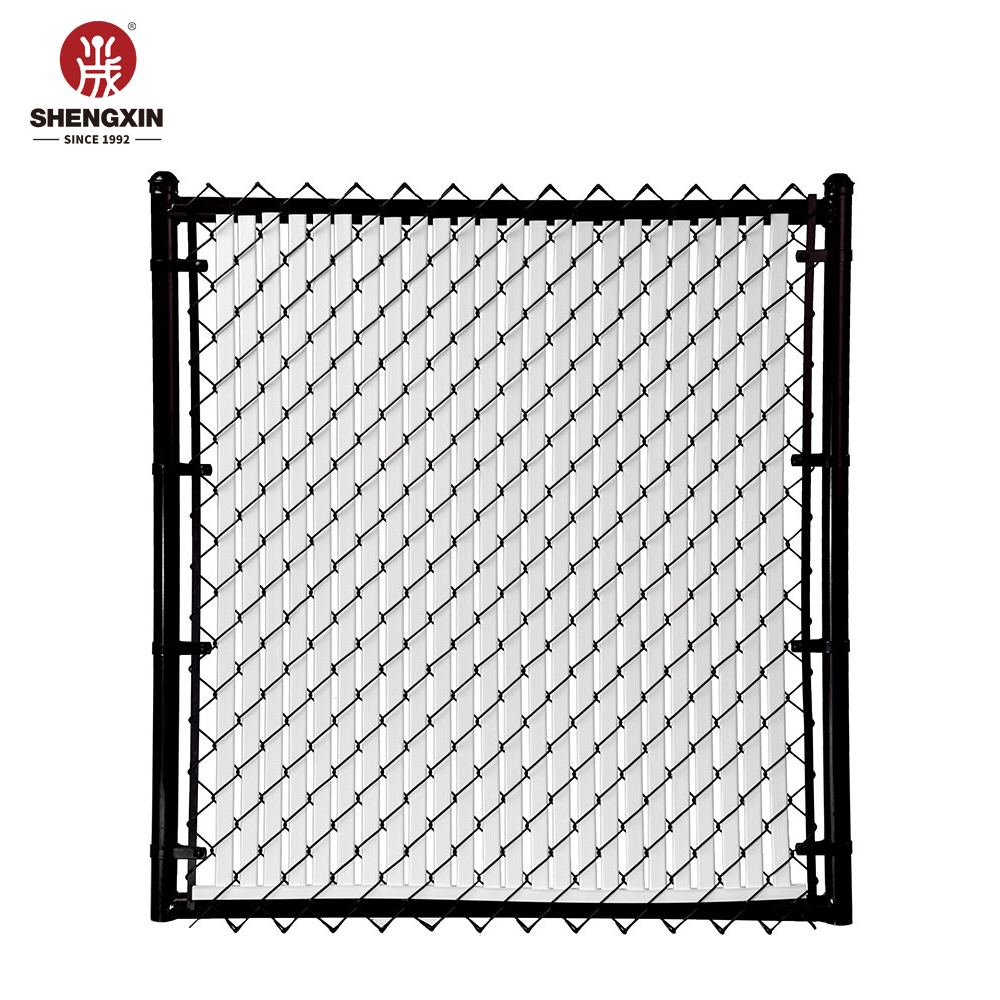

Customization has rapidly become the competitive cornerstone for chain link fence part producers. Beyond standard mesh sizes (50x50mm, 60x60mm), leading factories deliver powder-coating in up to 15 RAL colours, wire diameters from 2.0mm to 5.0mm, and custom-milled gate hardware. Around 68% of commercial fencing clients now request logo embossing or mesh weaving patterns unique to their brand. Modular assembly kits also allow rapid installation and future expansions, reducing overall project time by 30% on average.

Innovative solutions such as anti-uplift brackets, sound-reducing polymer strips, and privacy slats are increasingly offered as part of complete packages for urban, hospitality, and data center applications. Factories investing in CNC tooling and robotic welding can deliver design-to-shipment cycles within 10–14 days for tailored orders, compared to 30+ days for traditional hand-crafted suppliers.

Applications in Residential, Commercial, and Industrial Settings

Chain link fencing systems are utilized across a remarkably wide spectrum of projects, reflecting growing diversification in project requirements. In residential areas, pre-galvanized mesh with vinyl coating provides both property delineation and increased appeal, limiting corrosion and extending visual integrity for up to two decades.

Within commercial real estate and logistics, galvanized parts are often paired with anti-vandal fasteners and electronic surveillance integration. For industrial applications, such as utility substations and airports, heavy-gauge posts and impact-rated mesh are mandated by regulatory authorities for safety and anti-intrusion effectiveness. A 2023 industry survey highlighted that 82% of industrial respondents preferred suppliers offering pre-engineered, standards-compliant assembly modules to reduce installation errors and future-proof site security.

Market Trends and Cost Efficiency: Comparative Data Insights

The global chain link fence component market is projected to grow at a CAGR of 4.2% from 2024 to 2028, with the Asia-Pacific region leading at 5.7%. A significant factor driving this growth is efficiency in both material use and supply logistics. Innovative chain link fence part factories have demonstrated a 20–30% reduction in per-unit energy use over the last four years, owing to automation, precision cutting, and optimized coating lines.

The following comparative table shows example cost-per-linear-meter for three common purchasing models in 2024–2025:

| Model | Direct Factory | Regional Distributor | Onsite Customization |

|---|---|---|---|

| Base-inclusive (USD/linear meter) | $17–$21 | $23–$28 | $29–$37 |

| Average Lead Time (days) | 11 | 16 | 27 |

| Warranty Provided (years) | 12 | 8 | 10 |

These figures highlight the substantial savings and supply reliability achievable by sourcing directly from certified factories, especially for larger projects.

Conclusion: Insights into Trusted Chain Link Fence Part Suppliers

In summary, the pursuit of optimal chain link fence part solutions requires an informed approach to technical specifications, supplier competence, and application-driven customization. Reliable chain link fence part suppliers and factories not only guarantee compliance and performance but deliver the operational flexibility crucial for diverse and demanding projects. Cost-effective, certified components supported by modern logistics ensure that property developers and contractors sustain security, durability, and brand value. Accurate chain link fence part quotes now incorporate lifecycle savings and tailored options, enabling organizations to make strategic investments that stand the test of time. Choosing high-standard factories and suppliers is, unequivocally, the key to project success and lasting security infrastructure.

(chain link fence part)

FAQS on chain link fence part

Q: What types of chain link fence parts are commonly available?

A: Common chain link fence parts include posts, rails, fittings, gates, and tension bands. These parts are essential for installing and maintaining a secure fence. You can find them in a variety of sizes and materials from different suppliers.Q: How do I find a reliable chain link fence part factory?

A: Look for factories with good reviews, certifications, and experience in producing chain link fence parts. Visiting their official websites and checking customer feedback can also help assess reliability. Additionally, you can request product samples before making a bulk order.Q: Can chain link fence part suppliers provide customized parts?

A: Yes, many chain link fence part suppliers offer customization according to your specifications. This may include unique sizes, finishes, or materials. Contact suppliers directly to discuss your specific requirements.Q: How can I request quotes for chain link fence parts?

A: You can request quotes by contacting chain link fence part suppliers via their websites or email. Most suppliers provide quote forms for you to fill in your required specifications and quantity. They will respond with pricing and lead times.Q: What should I consider before purchasing parts from a chain link fence part factory?

A: Ensure the factory meets quality standards and can deliver on time. You should also compare prices, minimum order quantities, and shipping options. Asking for sample parts can help you verify product quality before making a larger purchase.This is the last article

-

High-Quality Chain Link Fence Parts Reliable Suppliers & Factory Prices

NewsJul.07,2025

-

Clear View Fence Anti Climb - High Security Fencing Factory & Suppliers Quotes

NewsJul.07,2025

-

Temporary Fence Business for Sale Factory Direct Suppliers & Best Quotes

NewsJul.06,2025

-

High-Quality Temporary Fence Fittings - Trusted Factory & Suppliers Get Quick Quotes

NewsJul.06,2025

-

High Quality 358 Fence High Security Fence Manufacturer Anti-Climb & Durable Solutions

NewsJul.06,2025

-

High-Quality Industrial Security Fence Solutions Reliable Factory & Suppliers

NewsJul.05,2025