Avg . 25, 2025 01:40 Back to list

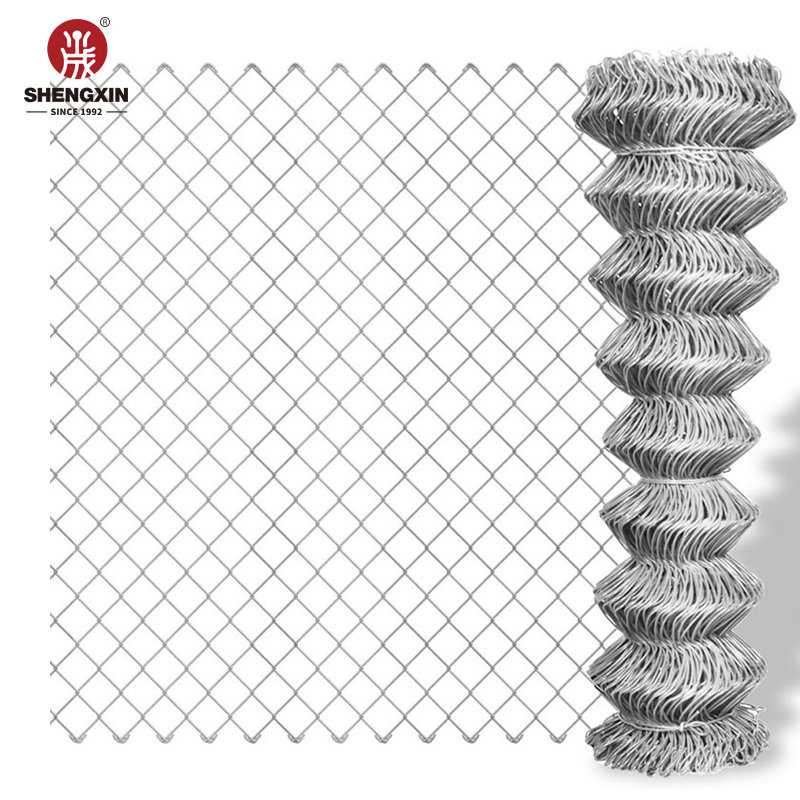

Durable Chain Link Fencing Wire - Secure & Quality Mesh Fences

Strategic Deployment of chain link fencing wire in Modern Infrastructure

In the realm of perimeter security and demarcation, the selection of robust and durable materials is paramount. chain link fencing wire stands as a foundational solution, widely recognized for its adaptability, cost-effectiveness, and inherent strength. This comprehensive overview delves into the critical aspects of modern chain link fence systems, focusing on the Powder Coated and Hot-Dipped Galvanized variants. These advanced treatments significantly extend the operational lifespan and enhance the aesthetic integration of the fence, making it an indispensable asset across a multitude of industrial and commercial applications. Understanding the intricate manufacturing processes, technical specifications, and strategic advantages of these systems is crucial for B2B decision-makers and engineering professionals aiming to optimize their security infrastructure.

Our discussion will cover the detailed manufacturing journey, delve into prevailing industry trends, meticulously outline technical specifications, explore diverse application scenarios, highlight distinct technical advantages, offer insights for vendor comparison, and showcase the potential for customized solutions, all underpinned by real-world application case studies. The aim is to provide a complete, authoritative resource for those evaluating the optimal deployment of chain link fencing wire solutions.

Advanced Manufacturing Process Flow for Chain Link Fencing Wire

The production of high-quality chain link fencing wire involves a precise, multi-stage manufacturing process designed to ensure durability, structural integrity, and long-term performance. This process begins with premium raw materials and culminates in a finished product that meets stringent international standards.

1. Material Procurement and Preparation

The foundation of superior chain link fencing wire is the quality of its raw materials. We utilize high-grade steel wire rods, typically conforming to ASTM A853 standards, ensuring optimal tensile strength and ductility. These rods undergo a descaling and cleaning process to remove impurities and prepare the surface for subsequent drawing operations.

2. Wire Drawing

The steel rods are progressively drawn through a series of dies to achieve the desired wire gauge (diameter). This cold-drawing process increases the tensile strength of the wire and refines its dimensions, ensuring consistent mesh size in the final product. Precision CNC wire drawing machines are employed to maintain tight tolerances, critical for manufacturing reliable chain link mesh fence products.

3. Galvanization (For Hot-Dipped Galvanized Variant)

For Hot-Dipped Galvanized (HDG) chain link fencing wire, the drawn wire is immersed in a bath of molten zinc. This process creates a metallurgically bonded coating of zinc that provides exceptional corrosion resistance, crucial for extended service life in harsh environments. The zinc coating weight typically adheres to ASTM A116 or ASTM A392 specifications, guaranteeing a protective barrier against rust and environmental degradation. The target industries benefiting from this level of corrosion resistance include petrochemical plants, coastal facilities, and agricultural operations.

4. Weaving/Knitting

Using automated weaving machines, the galvanized or raw steel wire is interlocked in a continuous diamond pattern, forming the characteristic chain link mesh fence. The machines are calibrated to produce precise mesh sizes (e.g., 2-inch, 2.25-inch) and wire gauges, with options for knuckled or barbed selvage edges to meet specific security requirements. This process is optimized for efficiency and consistency, minimizing material waste and ensuring uniform mesh integrity.

5. PVC Powder Coating (For Powder Coated Variant)

For Powder Coated chain link fencing wire, the woven galvanized mesh undergoes a sophisticated electrostatic powder coating process. The mesh is first thoroughly cleaned and pre-treated to ensure optimal adhesion. Electrostatic spray guns apply a fine PVC (Polyvinyl Chloride) powder, which is then cured in a high-temperature oven. This process creates a durable, aesthetically pleasing, and highly corrosion-resistant layer that offers enhanced UV stability and resistance to chipping, fading, and cracking. This coating is particularly advantageous in scenarios requiring both high corrosion resistance and specific aesthetic integration, such as public parks, sports facilities, and residential complexes. The service life of such fences can exceed 20 years, even in challenging climates.

6. Quality Control and Testing

Throughout the manufacturing process, rigorous quality control measures are implemented. This includes:

- Material Inspection: Verification of raw material composition and tensile strength.

- Dimensional Accuracy: Regular checks on wire gauge, mesh size, and roll dimensions.

- Coating Thickness: Measurement of zinc coating (for HDG) and PVC coating (for powder coated) to ensure compliance with ISO 1461, ASTM A392, and ASTM F668 standards.

- Adhesion Testing: For powder-coated wire, tests are performed to ensure superior bond strength of the coating.

- Corrosion Resistance Testing: Salt spray tests (e.g., ASTM B117) may be conducted to simulate accelerated corrosion environments.

Industry Trends and Market Dynamics for Chain Link Fencing

The market for chain link fencing wire is continuously evolving, driven by innovations in material science, heightened security demands, and a growing emphasis on sustainability. Key trends influencing demand include:

- Enhanced Durability and Longevity: Increasing preference for pre-treated wires, such as Class 2B or Class 3 galvanization and high-performance PVC coatings, which significantly extend fence lifespan and reduce maintenance costs. This is particularly relevant for large-scale infrastructure projects and industrial facilities where long-term investment protection is critical.

- Aesthetic Integration: A rising demand for colored PVC-coated chain link fences to blend seamlessly with environmental aesthetics. This trend is prominent in residential, recreational, and public sector projects where visual appeal is as important as security.

- Smart Fencing Solutions: Integration of traditional chain link mesh fence systems with security technologies such as intrusion detection sensors, CCTV, and access control systems, especially in high-security applications like data centers, airports, and military installations.

- Sustainable Practices: Growing emphasis on manufacturing processes that minimize environmental impact, including efficient resource utilization and recyclable materials. Suppliers offering certified sustainable products gain a competitive edge.

- Customization: Increased demand for tailor-made solutions concerning height, mesh size, wire gauge, and coating specifications to meet unique project requirements and specific security threats. The ability to provide customized solutions often distinguishes a premium wholesale chain link fence supplier.

Technical Specifications and Performance Parameters

The efficacy of chain link fencing wire is defined by its precise technical specifications, which dictate its strength, durability, and suitability for various environments. Understanding these parameters is crucial for informed procurement.

Key Product Specifications

| Parameter | Hot-Dipped Galvanized (HDG) | Powder Coated (PVC) |

|---|---|---|

| Material | High-Tensile Steel Wire (ASTM A853) | Galvanized Steel Wire + PVC Coating |

| Wire Gauge (BWG) | 6 BWG (4.88mm) to 12 BWG (2.64mm) | 9 BWG (3.76mm) to 12.5 BWG (2.41mm) |

| Mesh Size (Diamond) | 2" (50x50mm), 2.25" (57x57mm), 2.375" (60x60mm) | 2" (50x50mm), 2.375" (60x60mm), 2.5" (63x63mm) |

| Roll Height | 3 ft (0.9m) to 12 ft (3.6m) | 3 ft (0.9m) to 12 ft (3.6m) |

| Roll Length | 50 ft (15m), customized lengths available | 50 ft (15m), customized lengths available |

| Zinc Coating Weight | Min. 1.2 oz/sq ft (Class 1) to 2.0 oz/sq ft (Class 3) per ASTM A392 | Pre-galvanized, then PVC coated |

| PVC Coating Thickness | N/A | Typically 0.4mm to 0.5mm over galvanized wire |

| Tensile Strength | Min. 70,000 PSI (485 MPa) | Min. 70,000 PSI (485 MPa) (core wire) |

| Service Life (Estimated) | 15-20 years in typical environments | 20-30+ years with proper maintenance |

| Colors Available | Metallic Silver/Grey | Green, Black, Brown, White, Custom RAL |

These specifications allow engineers and project managers to select the most appropriate chain link fencing wire type for their specific application, considering factors such as environmental exposure, security level, and aesthetic requirements. Compliance with international standards like ISO 9001 (for manufacturing quality) and relevant ASTM specifications ensures product reliability and interoperability.

Diverse Application Scenarios and Target Industries

The versatility of chain link fencing wire allows its deployment across a wide array of industries and application scenarios, fulfilling diverse security, demarcation, and protective needs.

- Petrochemical and Energy Sector: Critical infrastructure like refineries, power plants, and oil & gas facilities utilize HDG chain link mesh fence for perimeter security, equipment enclosure, and zone demarcation. The corrosion resistance is vital in environments exposed to chemicals and harsh weather.

- Metallurgy and Mining: In mining operations and metallurgical plants, fences are required for safety around hazardous areas, storage of materials, and property delineation. The robust nature of galvanized chain link withstands abrasive conditions.

- Water Supply & Drainage Systems: Essential for securing reservoirs, pumping stations, water treatment facilities, and canals, preventing unauthorized access and protecting public safety. Powder-coated options offer both durability and discreet integration.

- Transportation Infrastructure: Used extensively along highways, railways, airports, and port facilities for boundary fencing, livestock control, and preventing pedestrian access to dangerous areas.

- Commercial and Industrial Parks: Providing cost-effective and reliable security for warehouses, manufacturing plants, logistics centers, and office parks. Often specified as wholesale chain link fence for large developments.

- Recreational Facilities: Common in sports fields, tennis courts, parks, and playgrounds, offering safety, ball containment, and clear boundaries with an emphasis on visual appeal through colored PVC coatings.

- Residential and Agricultural: For property demarcation, animal enclosures, and general security where robust and long-lasting fencing is required.

Technical Advantages of Our Chain Link Fencing Solutions

Our Powder Coated and Hot-Dipped Galvanized chain link fencing wire solutions offer distinct technical advantages designed to provide superior performance and value over their lifespan.

- Exceptional Corrosion Resistance: Hot-Dipped Galvanization creates a sacrificial zinc coating that protects the steel core from rust, even if scratched. Powder coating adds another impervious layer, providing dual protection against moisture, chemicals, and UV radiation, significantly extending the fence's life in aggressive environments. This reduces the total cost of ownership over time.

- High Tensile Strength and Durability: Manufactured from high-grade steel wire, our chain link mesh fence exhibits superior tensile strength, making it highly resistant to cutting, bending, and impact. This inherent strength contributes directly to enhanced security and structural integrity.

- Low Maintenance Requirements: The advanced protective coatings drastically reduce the need for frequent painting or repair, translating into significant labor and material cost savings over the fence's service life. This 'energy saving' aspect refers to the reduced energy footprint for maintenance and replacement.

- Versatility and Adaptability: Available in a wide range of wire gauges, mesh sizes, and heights, our products can be tailored to various security levels and aesthetic preferences. The flexibility of the mesh allows it to conform to uneven terrain.

- Cost-Effectiveness: Compared to other high-security fencing options, wholesale chain link fence offers a highly economical solution without compromising on security or longevity, particularly when considering its extended service life and low maintenance.

- Ease of Installation and Repair: The modular nature of chain link components facilitates relatively quick and straightforward installation. Damaged sections can be easily repaired or replaced, minimizing downtime and disruption.

Vendor Comparison Considerations for Chain Link Fencing Wire

When selecting a supplier for chain link fencing wire, B2B decision-makers must evaluate several critical factors beyond just initial price. A thorough vendor comparison ensures long-term reliability and cost-effectiveness.

Key Comparison Points

| Criterion | High-Value Vendor Attributes | Risk Indicators / Lower Value Attributes |

|---|---|---|

| Product Quality & Standards | ISO 9001 certified, ASTM, ANSI compliance, verifiable coating thickness/quality. | No verifiable certifications, vague product specs, inconsistent material quality. |

| Customization Capability | Ability to produce specific wire gauges, mesh sizes, coatings, and colors for complex projects. | Limited product range, inability to modify standard dimensions or finishes. |

| Lead Time & Logistics | Reliable, transparent lead times; efficient global logistics network. | Frequent delays, poor communication on shipping, limited delivery options. |

| After-Sales Support & Warranty | Comprehensive warranty (e.g., 10-20 years), dedicated technical support, spare parts availability. | Limited or unclear warranty, difficult to reach support, no post-purchase assistance. |

| Experience & Reputation | Years in industry, positive client testimonials, portfolio of large-scale projects, financial stability. | New or unproven supplier, negative reviews, lack of substantial project references. |

Choosing a vendor with a proven track record of delivering high-quality wholesale chain link fence products, coupled with excellent service and support, will mitigate risks and ensure project success.

Customized Solutions for Specialized Projects

Recognizing that no two projects are identical, we offer extensive customization options for our chain link fencing wire to meet the specific demands of unique applications. Our engineering team collaborates closely with clients to develop tailored solutions that align with stringent technical and operational requirements.

- Specific Wire Gauges and Mesh Sizes: From heavy-duty 6 BWG wire for maximum security applications to finer gauges for animal enclosures or aesthetic purposes, we can provide exact specifications. Mesh sizes can be adjusted for anti-climb properties or specific containment needs.

- Varied Coating Systems: Beyond standard HDG and PVC, we can explore specialized coatings for extreme chemical resistance, anti-graffiti properties, or enhanced UV protection. Custom color matching (e.g., specific RAL codes) for branding or environmental integration is also available for powder-coated fences.

- Height and Length Adjustments: Rolls can be manufactured to precise heights (up to 12ft or more) and specific lengths, reducing waste and simplifying installation for projects with non-standard dimensions.

- Selvage Options: Choice of knuckled (KK) or barbed (BB) selvage edges. Knuckled edges offer a smoother, safer finish suitable for public areas, while barbed edges provide increased security by deterring climbing. Double-barbed options are available for maximum security zones.

- Integrated Security Features: For high-security installations, we can provide mesh designed for easy integration with razor wire, barbed wire, or electronic intrusion detection systems, transforming a standard chain link mesh fence into a formidable barrier.

Our ability to deliver customized chain link fencing wire solutions, backed by a team of experienced engineers and strict adherence to manufacturing standards, ensures that even the most complex project specifications are met with precision and reliability.

Application Case Studies: Real-World Deployment of Chain Link Fencing

Case Study 1: Perimeter Security for a Major Data Center Complex

A leading global technology firm required a robust, long-lasting, and scalable perimeter security solution for its new data center in a coastal region. The primary concerns were corrosion resistance due to saline air and deterrence against unauthorized access.

- Solution Implemented: High-security chain link fencing wire (9 BWG, 2-inch mesh) with a Class 3 hot-dipped galvanized coating, further enhanced with a black PVC powder coating for aesthetic integration and additional environmental protection. The fence height was 10 feet, topped with three strands of barbed wire and integrated with fiber-optic intrusion detection sensors.

- Outcome: The dual-coated system provided unparalleled corrosion resistance, estimated to exceed 25 years of service life without significant maintenance. The robust mesh and integrated security features successfully created a formidable barrier, meeting the client's stringent security protocols and demonstrating the effectiveness of advanced chain link mesh fence solutions.

Case Study 2: Infrastructure Demarcation for a Municipal Water Treatment Plant

A municipal authority sought a durable and visually unobtrusive fencing solution for its expanded water treatment facility. Key requirements included long-term resistance to moisture and chemicals, along with a design that blended into the surrounding natural landscape.

- Solution Implemented: A green PVC-coated chain link fencing wire (11 BWG, 2.25-inch mesh) was selected. The base wire was pre-galvanized before the application of the green PVC, ensuring optimal corrosion protection against the humid environment and potential chemical splashes. The fence was installed with a knuckled top edge for safety in public-adjacent areas.

- Outcome: The chosen system effectively delineated the facility's perimeter, providing necessary security while aesthetically integrating with the environment. The PVC coating proved highly resistant to the damp conditions and chemical exposure, ensuring a low-maintenance solution with an anticipated service life exceeding two decades. The project demonstrated how high-quality wholesale chain link fence can meet both functional and aesthetic goals for public infrastructure.

Frequently Asked Questions (FAQ)

Q: What is the primary difference between Hot-Dipped Galvanized and Powder Coated chain link fencing wire?

A: Hot-Dipped Galvanized (HDG) wire is coated with a layer of zinc after fabrication, providing robust corrosion protection. Powder Coated wire, typically applied over a galvanized base, adds a layer of PVC for enhanced corrosion resistance, UV protection, and aesthetic options (various colors). PVC coated fences offer superior longevity and appearance, especially in harsh or visually sensitive environments.

Q: How does wire gauge affect the strength of chain link mesh fence?

A: Wire gauge refers to the diameter of the wire. A lower gauge number indicates a thicker wire. Thicker wire (e.g., 9 BWG) results in a stronger, more rigid fence, offering higher resistance to impact and cutting, which is suitable for high-security applications. Higher gauge numbers (e.g., 11 or 12.5 BWG) correspond to thinner, more flexible wire, often used for general demarcation or residential purposes.

Q: What is the typical lead time for a large order of wholesale chain link fence?

A: Lead times can vary based on order volume, customization requirements, and current production schedules. For standard products, typical lead times range from 2-4 weeks. For large or highly customized orders, it may extend to 6-8 weeks. We maintain transparent communication regarding production and shipping schedules and provide detailed lead time estimates at the quoting stage.

Q: What kind of warranty is offered on your chain link fencing wire products?

A: We offer comprehensive warranties against manufacturing defects and coating failure. Our Hot-Dipped Galvanized products typically carry a 10-year warranty, while our Powder Coated products are backed by a 15 to 20-year warranty, depending on the specific product line and application environment. Full warranty details are provided with each quotation and product delivery.

Commitment to Service: Lead Time, Warranty, and Support

Our commitment to our B2B partners extends beyond product quality to encompass reliable logistics, robust warranties, and comprehensive customer support, ensuring a seamless experience from inquiry to post-installation.

Lead Time and Fulfillment

We understand the critical importance of timely delivery for large-scale projects. Our streamlined manufacturing processes and established logistics network enable us to fulfill orders efficiently. Standard products are typically dispatched within 2-4 weeks, while custom specifications may require 4-8 weeks, depending on complexity and volume. We utilize advanced inventory management systems to ensure product availability for wholesale chain link fence orders and provide real-time updates on order status.

Warranty Commitments

We stand by the superior quality and durability of our chain link fencing wire. Our products are backed by industry-leading warranties:

- Hot-Dipped Galvanized: 10-year limited warranty against rust and material defects.

- Powder Coated: 15-20 year limited warranty against rust, peeling, cracking, and fading of the PVC coating.

Customer Support and After-Sales Service

Our dedicated customer support team is available to assist with technical inquiries, order tracking, and any post-installation support needed. We provide comprehensive documentation, including installation guides and maintenance recommendations, to ensure optimal performance and extend the service life of our chain link fencing wire. Our commitment is to forge long-term partnerships based on reliability, quality, and exceptional service.

Conclusion: The Enduring Value of Advanced Chain Link Fencing

The evolution of chain link fencing wire, particularly with the advent of advanced Hot-Dipped Galvanized and Powder Coated treatments, has transformed it into a sophisticated, high-performance security solution. Its adaptability across diverse industries, from the rigorous demands of petrochemical facilities to the aesthetic considerations of public spaces, underscores its enduring relevance.

By adhering to stringent manufacturing standards, embracing innovative coating technologies, and offering extensive customization, we deliver chain link mesh fence products that not only meet but exceed contemporary security and durability expectations. Our comprehensive approach, encompassing detailed process flows, robust technical specifications, and unwavering customer support, ensures that our partners receive optimal value and long-term reliability. For B2B stakeholders prioritizing both performance and return on investment, these advanced chain link solutions represent a strategic choice for current and future infrastructure security needs.

References

- ASTM International. (2018). ASTM A392/A392M-18, Standard Specification for Zinc-Coated Steel Chain-Link Fence Fabric. ASTM International.

- ASTM International. (2019). ASTM F668/F668M-19, Standard Specification for Poly(Vinyl Chloride) (PVC) and Other Organic Polymer-Coated Steel Chain-Link Fence Fabric. ASTM International.

- ISO. (2015). ISO 9001:2015, Quality management systems — Requirements. International Organization for Standardization.

- Galvanizers Association. (2020). The Corrosion Protection Mechanism of Zinc Coatings. Galvanizers Association Technical Notes.

- American Fence Association. (2021). Fence Industry Safety Manual. American Fence Association.

This is the last article

-

Durable Chain Link Fencing Wire - Secure & Quality Mesh Fences

NewsAug.25,2025

-

Durable 100% PVC Privacy Panels & Slats for Chain Link Fences

NewsAug.24,2025

-

Premium Galvanized Steel Fence Designs - Durable & Secure Panels

NewsAug.23,2025

-

ODM 7' Security Fence | 358 Anti-Climb Galvanized Panels

NewsAug.22,2025

-

3D Welded Wire Mesh Fence Panels with Peach Posts

NewsAug.21,2025

-

Australia Farm Fence Black Star Picket Y Post - Durable Metal Cattle Post

NewsAug.19,2025