Aug . 04, 2025 03:00 Back to list

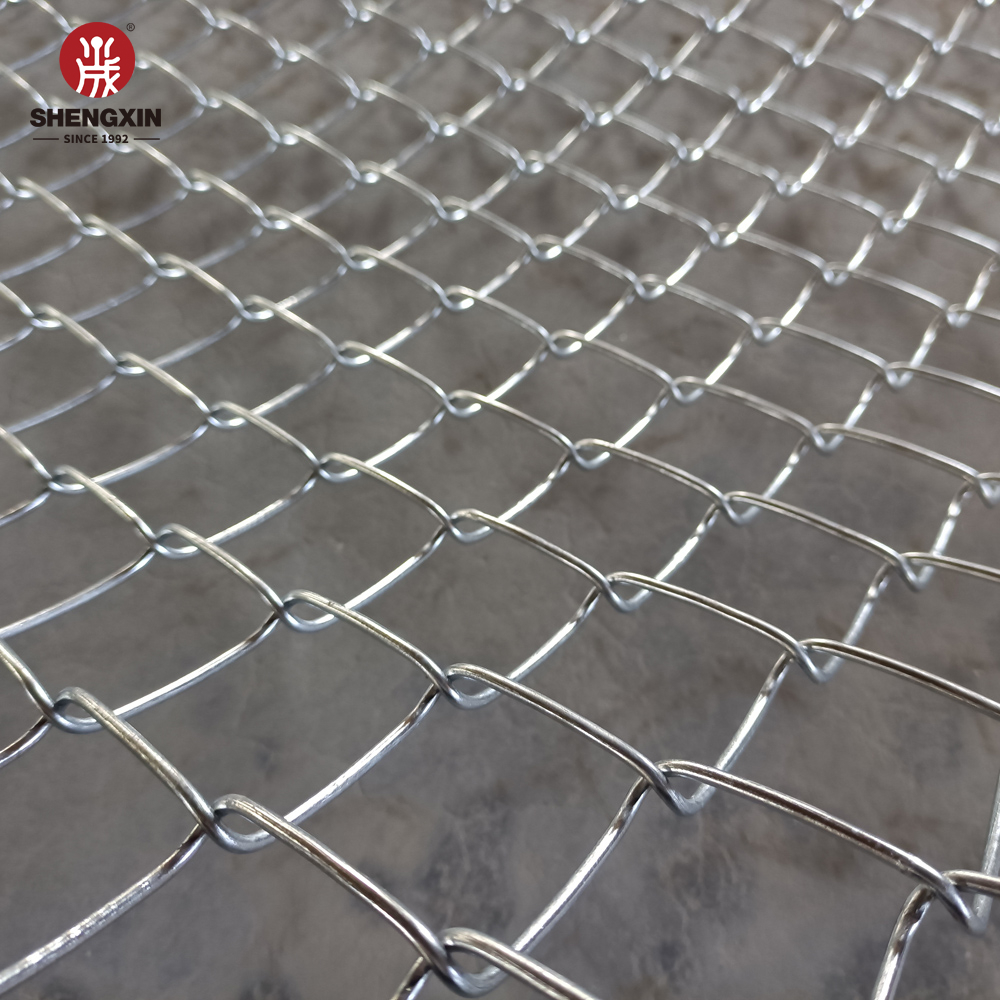

Coated Galvanized Steel Wire Mesh Fencing Panels | Durability & Protection

In today’s rapidly evolving security and infrastructure sectors, coating galvanized steel wire mesh fencing panels are at the forefront due to their outstanding corrosion resistance and durability. This article provides a deep-dive analysis of coating galvanized steel wire mesh fencing panels, focusing on advanced products such as Zinc - Aluminum Coating Wire / Galfan Wire Chain Link Fence, and related solutions like 3D curved welded wire mesh fence panel and 358 anti climb fence systems from premier suppliers and manufacturers worldwide.

The global market for coating galvanized steel wire mesh fencing panels has witnessed robust growth, reaching a value of USD 2.9 billion in 2023 (source: Grand View Research), and is projected to expand at a CAGR of 4.7% through 2030 due to increased applications in petrochemical, metallurgy, water supply, urban barrier, and security environments. In particular, high-performance fences such as the 358 anti climb fence are gaining traction as the premier choice in high-risk and industrial zones, supported by innovative coating techniques and rigorous compliance with international standards like ISO 1461, ASTM A974, and EN 10244-2.

China, Turkey, and Europe are dominant regions, with leading 358 anti climb fence manufacturers and exporters supplying cutting-edge security meshes to projects in North America, the Middle East, and Asia-Pacific.

| Parameter | 3D Curved Welded Wire Panel | 358 Anti Climb Mesh | Zinc-Aluminum Coating (Galfan) Chain Link |

|---|---|---|---|

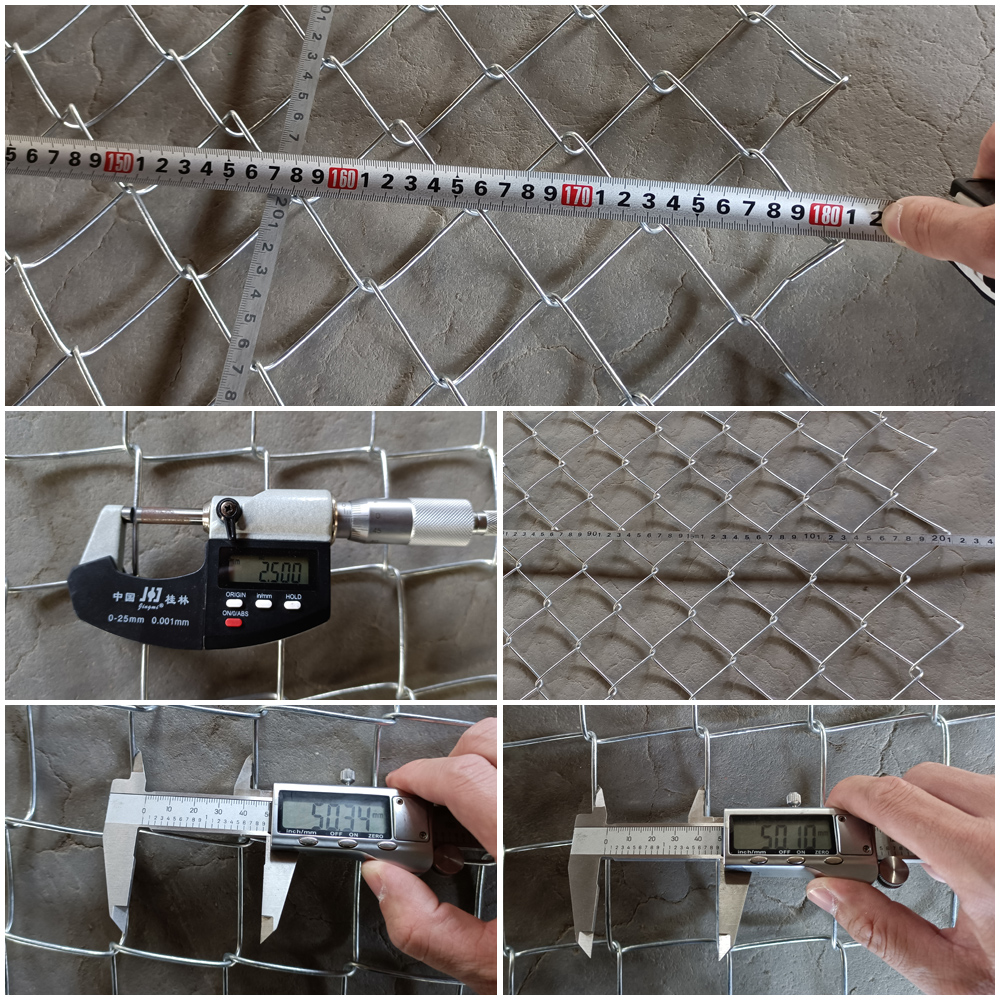

| Wire Diameter | 4.0–5.0 mm | 4.0 mm | 2.7–4.0 mm |

| Mesh Size | 50x200 mm | 12.7x76.2 mm | 50x50 mm / 60x60 mm |

| Height | 1.0–2.4 m | 1.2–3.6 m | 1.2–3.0 m |

| Coating Type | PVC / Hot-dip Zinc | Hot-dip Galvanized | Zinc-5%Al(Galfan) |

| Anti-corrosion Life | >10 Years | 20–30 Years | 30–40 Years |

| Application | Residential, Parks | Prisons, Airports, Industrial | Industrial, Public Works |

| Compliance | EN 10223-7, ISO 9001 | ASTM A974, ISO 1461 | ISO 9001, ASTM A764 |

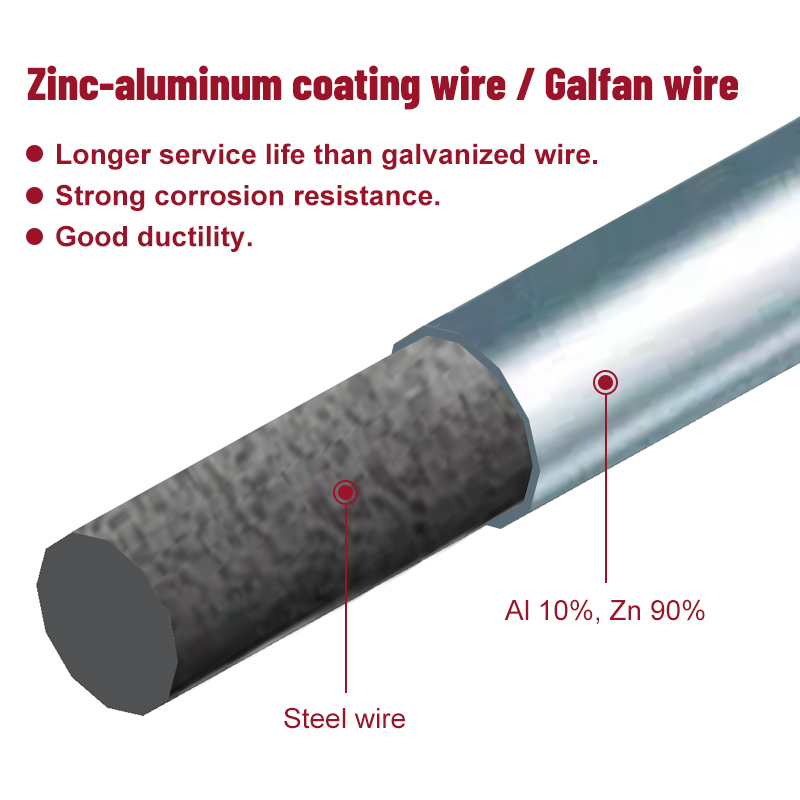

- Material: Low carbon steel (Q195/Q235), compliant with ISO 4948-1

- Coating: Galfan (Zn-5%Al mixed alloy), improved anti-corrosion by 2~3x compared to pure Zn coating (ref: Surface & Coatings Tech Journal)

- Welding: Resistance spot welding or CNC bending to achieve strong joints and precise mesh dimensions

- Testing: Salt spray (≥2000hrs), thickness, and adhesion as per ISO 1461 & ASTM B117

- Inspection: Each batch inspected for mesh uniformity, coating thickness, and mechanical strength

Galfan-coated fences showcase superior performance, especially in aggressive industrial and marine environments. Thanks to a patented Zn-5%Al alloy layer, Galfan delivers sacrificial and barrier protection, self-healing at scratches, and can outperform pure zinc or standard hot-dip finishes by triple the service life. This makes it an ideal solution for coating galvanized steel wire mesh fencing panels used by top-tier 358 anti climb fence manufacturers and global 358 anti climb fence exporters.

| Supplier | Country | Main Product | Cert. & Standards | Export Markets | Average Delivery |

|---|---|---|---|---|---|

| Hebei Giant Metal Technology | China | 358 / 3D Mesh, Galfan, Customization | ISO 9001, ISO 1461 | EU, Mideast, S. America | 18–25 Days |

| Bekaert Fencing | Belgium | Galfan Chain Link, Welded Mesh | ISO 9001, EN Standards | Global | 24–30 Days |

| Cavatorta Steel Fence | Italy | Galvanized & Galfan Mesh | ISO 14001, CE | Europe, N. Africa | 25–35 Days |

| Betafence | UK/Turkey | 358 Security Fence, Custom Mesh | ISO 9001, PAS 68 | United Kingdom, Africa | 15–22 Days |

Coating galvanized steel wire mesh fencing panels are deployed in a wide spectrum of high-value and critical scenarios:

- Petrochemical Facilities: Galfan chain link fence used in offshore oil platforms passes ISO 12944-6 corrosion class C5-M testing.

- Correctional & Security Prisons: 358 anti climb fence service ensures non-cuttable, anti-climb structures, noted for exceeding ASTM F2453 test standards.

- Industrial Waterworks: 3D curved welded wire mesh fence panels provide protective barriers with exceptional flow visibility and minimal maintenance.

- Airport Perimeters: Security mesh by 358 anti climb fence suppliers established at major airports in Dubai and Singapore.

- Urban & Highway Barriers: City governments select Galfan mesh for aesthetic, anti-vandal protection zones.

“Since switching to Galfan-coated fencing in 2019, system maintenance intervals have been reduced by 60%, with no visible red rust after 4 years in service.” – Shanghai Urban Pipeline Institute

First-class 358 anti climb fence factories and coating galvanized steel wire mesh fencing panels suppliers globally offer extensive customization:

- Custom mesh aperture, wire diameter (2.7–6.0mm), and panel dimensions (up to 3.6m x 2.4m)

- Flexible coatings: Galfan, Zn-Al-Mg, PVC/PE, or powder painted per RAL color chart

- Special applications: sensor integration for smart fencing, anti-cut/anti-climb enhancements, and modular panel kits

- Turnkey solutions with fast installation, precise anchoring accessories, and comprehensive after-sales service

| Certification | Details | Coverage |

|---|---|---|

| ISO 9001:2015 | Quality Management System | Manufacturing Process, Traceability |

| ISO 1461 | Hot-Dip Galvanized Coatings | Coating Thickness, Test Results |

| EN 10244-2 | Steel Wire & Finished Product Coating | Corrosion Life, Bond Strength |

- Average lead time: 15–25 days (subject to order volume and panel type)

- Warranty: 10–20 years against corrosion, with full technical support

- Support: 24/7 consultation, onsite guidance, installation manuals, OEM branding

- Global shipping: Export-licensed, pallet or crate-packed for maximum protection

For more detailed technical discussion and user experiences, explore:

This is the last article

-

Coated Galvanized Steel Wire Mesh Fencing Panels | Durability & Protection

NewsAug.04,2025

-

Powder Coated Double Wire Mesh Fence-Anping County Shengxin Metal Products Co., Ltd

NewsAug.03,2025

-

Powder Coated Double Wire Mesh Fence - Anping County Shengxin Metal Products Co., Ltd

NewsAug.03,2025

-

Power Coated 358 Anti Climb Mesh Fence for Airports

NewsAug.03,2025

-

Powder Coated Double Wire Mesh Fence-Anping County Shengxin Metal Products Co., Ltd.

NewsAug.02,2025

-

Powder Coated Double Wire Mesh Fence | Anping County Shengxin Metal Products Co., Ltd

NewsAug.02,2025