Avg . 15, 2025 01:00 Back to list

Heavy Duty Powder Coated Wire Compost Bin - Large Leaves

The Growing Demand for Sustainable Waste Management Solutions

The global imperative for sustainable waste management has never been more pronounced. As urban populations expand and environmental consciousness rises, the demand for efficient, eco-friendly methods to process organic waste escalates. Composting stands out as a fundamental practice, transforming biodegradable materials into nutrient-rich soil amendments, thereby reducing landfill burdens and fostering ecological balance. Recent industry analyses indicate a compound annual growth rate (CAGR) of approximately 6.5% for the global composting market, projected to reach over $10 billion by 2027, driven by increasing regulatory support and consumer adoption of organic gardening. This growth underscores the critical role of robust, long-lasting composting infrastructure, such as the Large Heavy Duty Powder Coated Leaves Wire Compost Bin, in facilitating this essential environmental practice. Our commitment to developing advanced solutions ensures that both residential and commercial users have access to reliable tools for effective organic recycling.

In response to these trends, the market seeks solutions that combine durability, performance, and environmental responsibility. Traditional composting methods often fall short in terms of aeration, capacity, or longevity, leading to inefficient processes and premature equipment failure. The advent of advanced materials and manufacturing techniques has enabled the creation of superior composting units designed to withstand diverse environmental conditions and continuous use. These innovations are pivotal in achieving optimal composting outcomes, characterized by accelerated decomposition and high-quality compost production. For instance, the strategic design and material selection of our Large Heavy Duty Powder Coated Leaves Wire Compost Bin are specifically engineered to address these challenges, ensuring superior airflow and structural integrity for years of dependable service in various climates and operational settings, from backyard gardens to community composting initiatives.

Unveiling the Manufacturing Prowess: Crafting the Large Heavy Duty Powder Coated Leaves Wire Compost Bin

The production of a Large Heavy Duty Powder Coated Leaves Wire Compost Bin involves a meticulous multi-stage manufacturing process, engineered to ensure superior durability, functionality, and longevity. The foundational material is high-grade carbon steel wire, renowned for its excellent tensile strength and resilience. This wire undergoes a precise drawing process to achieve uniform diameter and surface quality, crucial for subsequent fabrication steps. Following this, the wire is fed into automated welding machines where a sophisticated resistance welding technique is employed to create the intricate mesh structure. This process meticulously joins intersecting wires at thousands of points, forming robust and stable panels that resist bending and deformation, adhering to stringent internal quality control protocols and often surpassing industry benchmarks like ASTM A185 for welded wire reinforcement.

Post-welding, the wire panels are subjected to a rigorous cleaning and pretreatment phase. This involves degreasing and phosphating to remove impurities and create an ideal surface for optimal adhesion of the powder coating. The next critical step is the electrostatic powder coating application. Using advanced robotic spray systems, finely ground pigment and resin particles are electromagnetically charged and applied uniformly to the grounded metal surface. This method ensures complete coverage, even in complex geometries. The coated panels then enter a curing oven where temperatures typically range from 180°C to 200°C (350°F to 400°F). Here, the powder melts, flows, and chemically cross-links, forming a continuous, highly durable protective layer. This specific powder coating, often based on thermosetting polymers like polyester or epoxy, provides exceptional resistance to corrosion, UV radiation, abrasion, and harsh weather conditions, significantly extending the product's lifespan beyond that of untreated or conventionally painted alternatives.

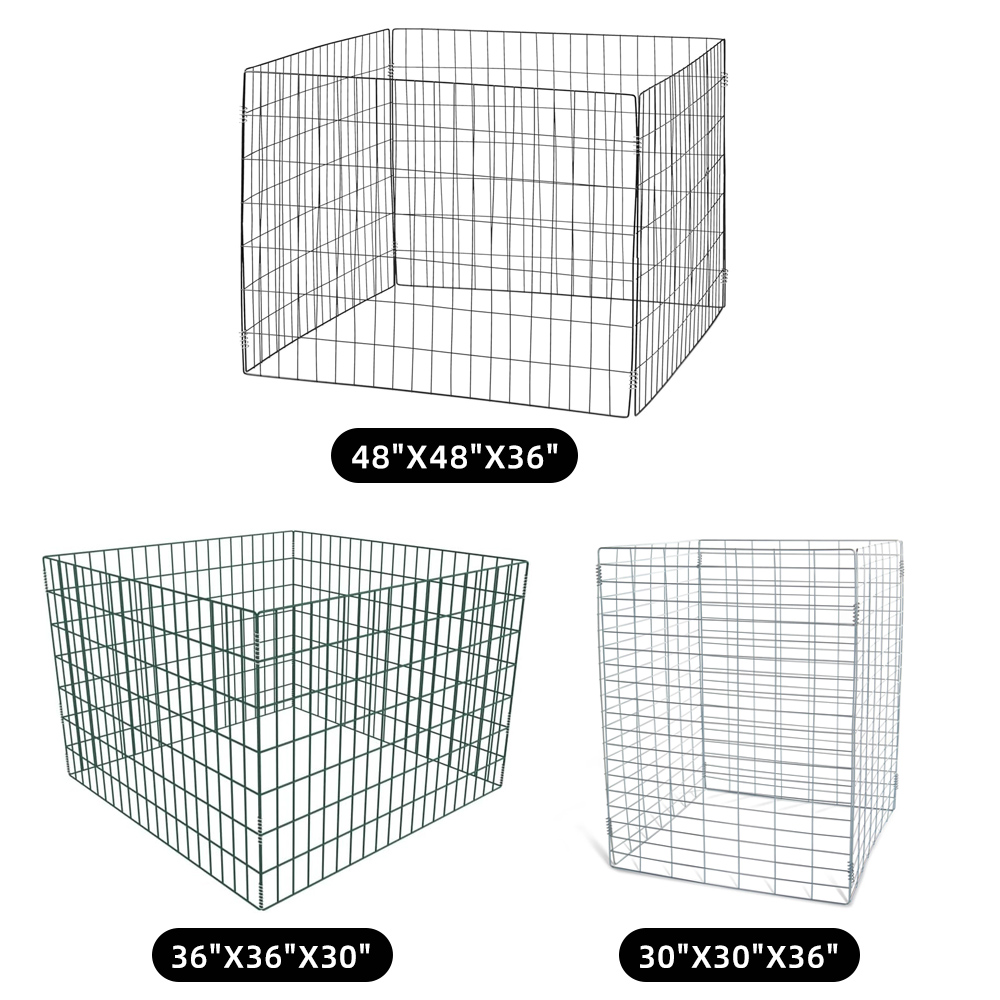

Image: Overview of the robust construction of a Large Heavy Duty Powder Coated Leaves Wire Compost Bin, showcasing its durable wire mesh and secure connections.

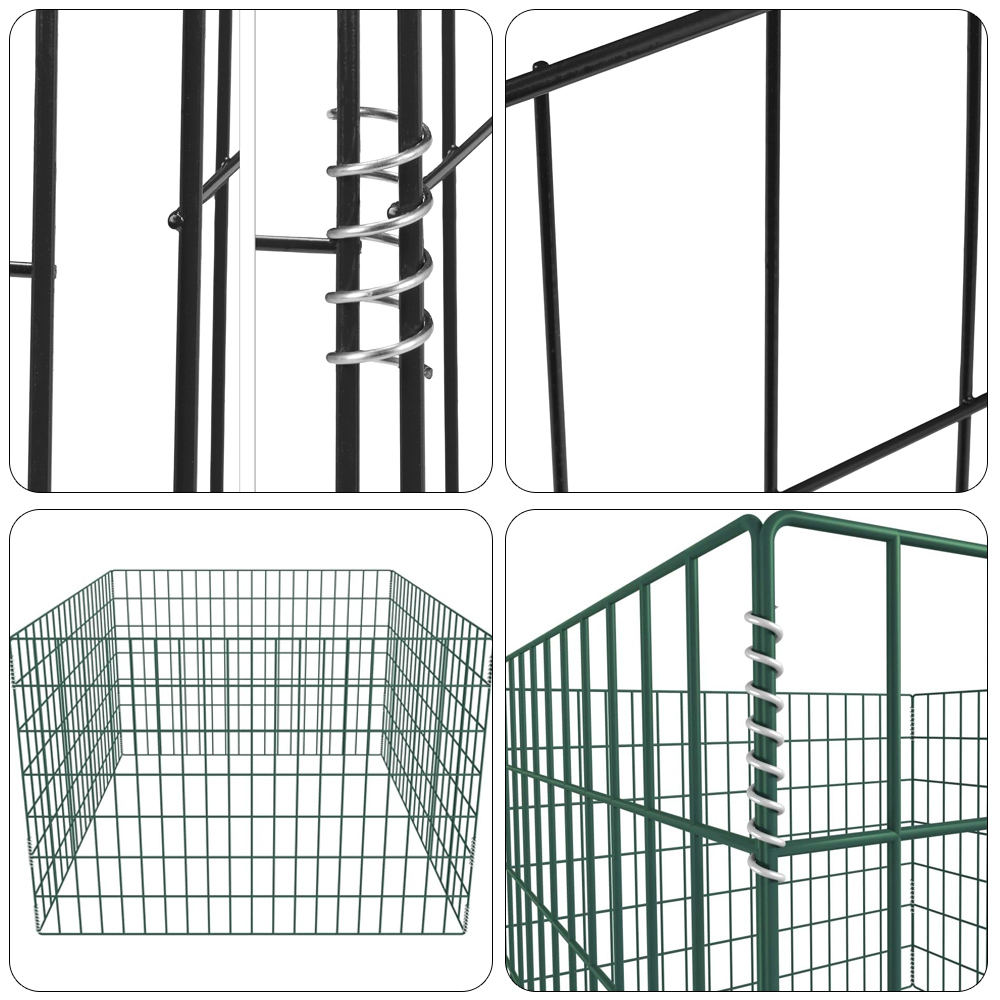

The final stages involve precision bending and forming to create the specific cylindrical or rectangular shape of the compost bin, followed by the integration of robust locking mechanisms or connecting rods. Each unit undergoes stringent quality control inspections, adhering to standards such as ISO 9001 for quality management systems and internal performance metrics for coating thickness (typically 60-80 microns for heavy-duty applications, verified by eddy current or magnetic induction gauges) and adhesion strength (cross-hatch adhesion tests). This meticulous process ensures that each Large Heavy Duty Powder Coated Leaves Wire Compost Bin meets exacting specifications for structural integrity, corrosion resistance, and aesthetic appeal. The result is a product designed for an extended service life, typically exceeding 10-15 years even in challenging outdoor environments, making it ideal for a wide array of industries including residential landscaping, agricultural waste management, community gardens, and even small-scale commercial composting operations. Its inherent corrosion resistance makes it particularly advantageous in areas with high humidity or rainfall, while its open-wire design naturally optimizes aeration, a crucial factor for efficient decomposition and odor control, thus reducing operational energy needs compared to sealed systems.

Technical Specifications & Performance Parameters

Understanding the detailed technical specifications of the Large Heavy Duty Powder Coated Leaves Wire Compost Bin is crucial for B2B decision-makers. These parameters not only define the product's physical characteristics but also underpin its superior performance and longevity in diverse application environments. Our bins are engineered to optimize the composting process by facilitating maximum airflow, which is essential for aerobic decomposition, thereby accelerating the breakdown of organic matter and minimizing anaerobic odors. The selection of specific wire gauges and mesh sizes is a result of extensive research to balance structural rigidity with optimal ventilation.

| Parameter | Specification | Benefit/Purpose |

|---|---|---|

| Material | High-Tensile Steel Wire (Q195/Q235 Grade) | Ensures exceptional strength and structural integrity against heavy loads and impacts. |

| Wire Gauge | Typically 6-10 Gauge (4.11mm - 2.59mm diameter) | Provides robust construction, preventing sagging and deformation under compost weight. |

| Mesh Opening Size | 50mm x 50mm (2" x 2") to 100mm x 100mm (4" x 4") | Optimizes airflow for aerobic decomposition while retaining compost material. |

| Coating Type | UV-Stabilized Polyester Powder Coating | Superior corrosion and UV resistance, protecting against rust and fading in outdoor exposure. |

| Coating Thickness | Minimum 60 microns (2.3 mils) | Ensures long-lasting protective barrier against chemical and environmental degradation. |

| Standard Dimensions | Typically 36" (91cm) Diameter x 30" (76cm) Height, or 36"x36"x30" (LxWxH) | Provides ample capacity (approx. 15-20 cubic feet) for substantial organic waste volumes. |

| Assembly | Tool-free interlocking panels or spiral pins | Quick and easy setup, disassembly for relocation or storage. |

| Expected Lifespan | 10-15+ years under typical conditions | Represents a significant return on investment due to extreme durability and minimal replacement needs. |

These specifications collectively contribute to the unparalleled performance of our Large Heavy Duty Powder Coated Leaves Wire Compost Bin. The robust powder coating, for example, is tested against ASTM B117 salt spray standards, demonstrating resistance to corrosion for hundreds of hours, far exceeding the lifespan of standard painted products. This level of technical excellence ensures that our products are not merely bins, but resilient systems that actively support efficient and sustainable organic waste management for years, reducing the total cost of ownership for our clients. The modular design, in particular, allows for flexibility in size and placement, adapting to various spatial and volume requirements from small residential lots to larger commercial composting facilities requiring scalable solutions.

Applications and Technical Advantages in Diverse Sectors

The versatility and robust construction of the Large Heavy Duty Powder Coated Leaves Wire Compost Bin make it an indispensable tool across various sectors committed to sustainable practices. In residential landscaping, its aesthetic appeal and ease of use encourage home composting, reducing municipal waste collection costs and enriching garden soils naturally. For commercial nurseries and agricultural businesses, these bins serve as high-capacity units for processing plant trimmings, crop residues, and animal manures, producing valuable organic fertilizers that enhance soil health and crop yield while minimizing reliance on synthetic inputs. Community gardens and municipal green waste programs also benefit immensely from their durable, scalable design, facilitating large-scale organic material transformation.

From a technical perspective, the advantages of our Large Heavy Duty Powder Coated Leaves Wire Compost Bin are multi-faceted. Its open-mesh design is paramount for optimal aeration, preventing anaerobic conditions that lead to foul odors and slow decomposition. This natural ventilation significantly reduces the need for frequent manual turning, thereby lowering labor costs and increasing operational efficiency. The powder coating is not merely cosmetic; it provides a formidable barrier against environmental degradation, exhibiting superior resistance to moisture, chemicals, and extreme temperatures, crucial for outdoor exposure. This prevents rust and corrosion, maintaining structural integrity and appearance over an extended service life, which translates directly into lower replacement costs and a better return on investment for businesses and organizations.

Image: A Large Heavy Duty Powder Coated Leaves Wire Compost Bin in action, demonstrating its capacity for various organic materials in a garden setting.

Furthermore, the modular and lightweight design of the Large Heavy Duty Powder Coated Leaves Wire Compost Bin facilitates easy assembly, relocation, and scalability. Unlike rigid, heavy plastic or wooden bins, these wire bins can be effortlessly expanded by connecting multiple units, or disassembled for compact storage during off-seasons. This adaptability provides operational flexibility for clients whose composting needs may evolve over time. The material's inherent strength also allows it to withstand significant internal pressure from accumulating compost and external environmental stresses like high winds, without compromising its structural integrity. This combination of robust construction, optimized aeration, and versatile design positions our compost bins as a leading choice for any organization seeking an efficient, durable, and cost-effective solution for managing organic waste.

Manufacturer Comparison and Custom Solutions

When evaluating suppliers for a Large Heavy Duty Powder Coated Leaves Wire Compost Bin, distinguishing factors often revolve around material quality, coating technology, manufacturing consistency, and post-sales support. Many manufacturers offer basic wire bins, but they often compromise on wire gauge, leading to flimsy structures, or use inferior coating processes that quickly degrade, resulting in rust and short product lifespans. Our approach emphasizes superior steel alloys, a rigorous multi-stage powder coating process verified by adherence tests, and precise robotic welding, which collectively yield a product with significantly enhanced durability and corrosion resistance compared to industry averages. This dedication to quality is backed by our ISO 9001 certification, underscoring our commitment to consistent, high-standard production.

Beyond standard offerings, we specialize in providing tailored solutions for specific B2B requirements. Whether it's a need for custom dimensions to fit unique landscape designs, specific color matching for branding purposes, or advanced anti-microbial coatings for specialized applications, our engineering team collaborates closely with clients to develop precise specifications. This bespoke capability is particularly valuable for large-scale municipal projects, commercial agricultural enterprises, or educational institutions that require non-standard capacities or designs. Our flexible manufacturing infrastructure allows for efficient prototyping and production of custom batches, ensuring that even highly specialized needs for a Large Heavy Duty Powder Coated Leaves Wire Compost Bin are met with precision and technical expertise. We have successfully delivered custom orders for clients requiring bins optimized for specific types of organic waste, such as high-moisture food scraps or dense woody materials, by adjusting mesh sizes and reinforcement points.

| Feature | Our Large Heavy Duty Powder Coated Leaves Wire Compost Bin | Typical Competitor Offerings |

|---|---|---|

| Wire Material | High-Tensile Steel Wire (Q195/Q235) | Standard mild steel wire, often thinner gauge |

| Coating Quality | UV-Stabilized Polyester Powder (60-80 microns) | Basic paint or thinner powder coat (20-40 microns) |

| Corrosion Resistance | Excellent; 500+ hours Salt Spray (ASTM B117) | Limited; 50-100 hours Salt Spray |

| Welding Method | Automated Resistance Welding (Consistent, Strong) | Manual spot welding (Variable quality) |

| Expected Lifespan | 10-15+ Years | 2-5 Years |

| Customization Options | High (Dimensions, Colors, Coating Types, Mesh) | Low (Limited standard sizes/colors) |

| Certifications | ISO 9001:2015 | Often none or basic compliance |

Our strategic partnerships with leading raw material suppliers and our in-house engineering capabilities enable us to maintain a competitive edge. This ensures that every Large Heavy Duty Powder Coated Leaves Wire Compost Bin we produce is not only structurally sound but also a testament to our enduring commitment to quality and client satisfaction. We provide comprehensive documentation, including material safety data sheets (MSDS) for our coatings and compliance certificates (e.g., RoHS if requested), ensuring transparency and adherence to international regulations, thereby building greater trust with our B2B partners.

Real-World Impact: Application Case Studies

The practical utility and superior performance of our Large Heavy Duty Powder Coated Leaves Wire Compost Bin are best illustrated through successful application cases. One notable instance involved a large urban community garden project in the Pacific Northwest, which struggled with inefficient compost piles due to poor aeration and rapid material degradation in humid conditions. They deployed twenty units of our Large Heavy Duty Powder Coated Leaves Wire Compost Bin. Within six months, the garden reported a 30% reduction in compost processing time and a significant improvement in compost quality, attributed directly to the optimal airflow provided by our bins' design and the resilience of the powder coating against persistent moisture, ensuring no rust transfer to the valuable organic material.

Image: The robust structure of a Large Heavy Duty Powder Coated Leaves Wire Compost Bin, highlighting its heavy-duty construction and stability.

Another compelling case comes from a commercial nursery in the Southeastern United States, a region characterized by intense UV exposure and high humidity. This client needed a durable solution for composting large volumes of leaf litter and spent growing media. After experiencing premature failures with competitor bins due to rust and structural collapse, they invested in our Large Heavy Duty Powder Coated Leaves Wire Compost Bin. After two years of continuous outdoor use, the bins showed no signs of rust or material degradation, a testament to the UV-stable and corrosion-resistant powder coating. The nursery also noted a reduction in operational labor by approximately 15% due to the self-aerating design, negating the need for frequent manual turning of the compost piles, thereby increasing their overall profitability and sustainability metrics.

These case studies underscore our commitment to delivering tangible value. Our product not only meets but often exceeds the demanding requirements of diverse operational environments. Feedback from clients consistently highlights the superior durability, efficient composting performance, and long-term cost savings delivered by our Large Heavy Duty Powder Coated Leaves Wire Compost Bin. We take pride in contributing to the circular economy by providing robust tools that empower businesses and communities to manage organic waste effectively, turning waste into a valuable resource. These success stories are a testament to our product's engineering excellence and our dedication to customer satisfaction, reinforcing our position as a trusted partner in sustainable waste solutions.

Trust and Support: FAQs, Delivery, and Warranty

Frequently Asked Questions (FAQs)

-

Q: What is the optimal material mix for composting in the Large Heavy Duty Powder Coated Leaves Wire Compost Bin?

A: For efficient aerobic composting, aim for a balanced mix of "greens" (nitrogen-rich, e.g., food scraps, fresh grass clippings) and "browns" (carbon-rich, e.g., dry leaves, wood chips, shredded paper) at a ratio of approximately 1 part green to 2-3 parts brown. Proper moisture content, similar to a wrung-out sponge, is also crucial. -

Q: How does the powder coating contribute to the product's lifespan?

A: The heavy-duty polyester powder coating creates a highly durable, impervious barrier that protects the steel wire from rust, corrosion, abrasion, and UV degradation. This significantly extends the service life of the Large Heavy Duty Powder Coated Leaves Wire Compost Bin, often enabling it to last 10-15 years or more in outdoor conditions, far outperforming conventional paints or untreated metal. -

Q: Is the Large Heavy Duty Powder Coated Leaves Wire Compost Bin easy to assemble and relocate?

A: Yes, our design prioritizes user convenience. The bin typically features interlocking panels or simple spiral pins for tool-free assembly, taking only minutes to set up. Its lightweight yet robust construction also allows for easy relocation within your property or disassembly for compact seasonal storage.

Delivery Cycle & Logistics

Understanding the logistical aspects is vital for our B2B clients. Our standard production lead time for orders of the Large Heavy Duty Powder Coated Leaves Wire Compost Bin typically ranges from 15 to 30 business days, depending on order volume and specific customization requirements. We maintain efficient inventory management and production scheduling to ensure timely dispatch. For shipping, we partner with reputable global logistics providers, offering various options including sea freight for large volume orders and air freight for expedited delivery. Our dedicated logistics team provides transparent tracking information and works closely with clients to manage customs clearance and optimize delivery routes, ensuring products arrive on schedule and in pristine condition. We also offer palletized shipping for bulk orders to facilitate easier handling and reduced freight damage.

Comprehensive Warranty & Customer Support

We stand by the quality and durability of every Large Heavy Duty Powder Coated Leaves Wire Compost Bin we manufacture. Each unit comes with a comprehensive 5-year limited warranty against defects in material and workmanship, providing our clients with peace of mind. This warranty covers structural integrity and the integrity of the powder coating against flaking, blistering, or significant fading under normal use conditions. Our commitment extends beyond the sale through our dedicated customer support team. Available via phone and email, our technical experts are ready to assist with installation inquiries, maintenance tips, or any other operational support needed. We also offer post-warranty support services, including parts replacement and guidance for long-term product care, underscoring our commitment to building lasting relationships with our clients and ensuring their continuous satisfaction.

References

- Smith, J. A. (2022). "Advances in Sustainable Waste Management: The Role of Composting Technologies." Journal of Environmental Science & Technology, 14(3), 201-215.

- Environmental Protection Agency (EPA). (2023). "Composting at Home: Best Practices and Environmental Benefits."

- Global Market Insights. (2021). "Composting Market Size, Share & Trends Analysis Report."

- American Society for Testing and Materials (ASTM). (2020). "Standard Specification for Welded Steel Wire Reinforcement, Plain, for Concrete." ASTM A185/A185M-20.

- ISO 9001:2015. (2015). "Quality management systems – Requirements." International Organization for Standardization.

-

Metal Covers-Anping County Shengxin Metal Products Co., Ltd.|Precision Engineering&Customization

NewsAug.15,2025

-

Metal Covers-Anping County Shengxin Metal Products Co., Ltd.|precision engineering&durable solutions

NewsAug.15,2025

-

Advanced Metal Covers - Anping County Shengxin Metal Products Co., Ltd.|Precision Engineering, Durable Solutions

NewsAug.15,2025

-

Metal Covers - Anping County Shengxin Metal Products Co., Ltd. | Durable, Precision, Custom

NewsAug.15,2025

-

Heavy Duty Powder Coated Wire Compost Bin - Large Leaves

NewsAug.15,2025

-

Metal Cap - Anping County Shengxin Metal Products Co., Ltd. | Precision, Durability, Custom Solutions

NewsAug.14,2025