Th8 . 26, 2025 01:40 Back to list

Galvanized Grape Vineyard Posts: Durable Metal Trellis Poles

The Evolution and Critical Role of Vineyard Trellis Systems

The viticulture industry, a sector historically rooted in tradition, is continually embracing technological advancements to optimize yield, ensure crop health, and enhance operational efficiency. A cornerstone of modern vineyard management is the trellis system, which provides crucial structural support for grapevines, influencing everything from sunlight exposure and air circulation to ease of harvesting. Amidst this evolution, the Galvanized Grape Vineyard Post Metal Pole Vineyard Trellis Post has emerged as a paramount solution, offering unparalleled durability and performance for contemporary viticultural practices.

Industry trends indicate a significant shift towards more sustainable, long-lasting, and low-maintenance vineyard infrastructure. Traditional wood posts, while historically common, present challenges such as rot, pest infestation, and a shorter service life, necessitating frequent replacement and increased labor costs. Steel posts, particularly those featuring advanced galvanization techniques, address these deficiencies head-on. The global viticulture market is projected to reach USD 30.5 billion by 2027, driven by consumer demand for high-quality wines and operational efficiencies in grape production, further emphasizing the need for robust and reliable vineyard infrastructure components.

The demand for resilient trellising components is also influenced by climate change, with vineyards facing increasingly unpredictable weather patterns, including stronger winds and heavier precipitation. Steel posts, engineered for superior strength and resilience, provide the stability required to withstand such environmental stressors, protecting valuable crops and ensuring vineyard longevity. This section will delve into the technical intricacies, application benefits, and strategic advantages of utilizing state-of-the-art metal posts for vineyard trellising.

Manufacturing Process: Precision Engineering for Durability

The production of a high-performance Galvanized Grape Vineyard Post Metal Pole Vineyard Trellis Post is a multi-stage process, meticulously controlled to ensure superior quality and extended service life. Each step, from material selection to final inspection, adheres to stringent international standards, guaranteeing a product capable of enduring harsh agricultural environments for decades.

Key Materials and Pre-Treatment:

- High-Tensile Steel Selection: The foundation of our posts is typically high-grade structural steel, conforming to standards such as ASTM A36 or equivalent European EN standards (e.g., S235JR, S355JR). This ensures optimal strength-to-weight ratio and resilience against bending forces and impact.

- Surface Preparation: Before galvanization, steel profiles undergo thorough cleaning. This includes degreasing to remove oils and greases, acid pickling (hydrochloric or sulfuric acid) to eliminate mill scale and rust, and finally, fluxing in a zinc ammonium chloride solution to prepare the surface for optimal zinc adhesion. This critical pre-treatment prevents delamination and ensures a uniform, protective coating.

Core Manufacturing Stages:

- Cold Rolling/Forming: Steel sheets or coils are precision cold-rolled into the desired profile, typically a 'Y', 'U', 'C', or 'V' shape. This cold-forming process increases the steel's yield strength and improves dimensional accuracy.

- Punching and Notching: Automated CNC machinery is employed to precisely punch holes and notches along the post length. These features are critical for attaching trellis wires, enabling easy wire adjustment and secure fastening. CNC machining ensures consistent hole placement and clean edges, crucial for preventing wire damage.

- Cutting to Length: Posts are cut to specific client-requested lengths, typically ranging from 1.8 meters to 3.0 meters, using high-precision cutting equipment.

- Hot-Dip Galvanization: This is the defining process for the Galvanized Grape Vineyard Post Metal Pole Vineyard Trellis Post. The prepared steel posts are submerged into a bath of molten zinc (maintained at approximately 450°C). A metallurgical bond forms between the steel and zinc, creating a highly durable, corrosion-resistant coating. The thickness of this zinc coating is critical for longevity and typically adheres to ISO 1461, ASTM A123, or AS/NZS 4680 standards, ensuring a minimum average coating thickness of 65-85 microns, depending on steel thickness. This sacrificial protection mechanism significantly extends the post's service life beyond 30 years in typical agricultural environments.

- Quenching and Finishing: After withdrawal from the zinc bath, posts are cooled (quenched) and inspected for coating uniformity, adherence, and overall finish. Any sharp edges or zinc drips are removed to ensure safe handling and wire protection.

Quality Control and Testing:

Each batch of posts undergoes rigorous testing and quality control:

- Coating Thickness Measurement: Non-destructive magnetic or eddy current gauges verify zinc coating thickness according to ISO 2178 or ASTM B499.

- Adhesion Testing: A hammer test or chisel test (as per ISO 1461, Annex C) confirms the strong metallurgical bond between zinc and steel.

- Visual Inspection: Checks for surface imperfections, bare spots, excessive dross, or uneven coating.

- Dimensional Verification: Ensuring posts meet specified lengths, profiles, and hole spacing.

Target industries for these posts include not only viticulture but also general agriculture for fencing and crop support, demonstrating their versatility and robust construction. The emphasis on corrosion resistance and extended service life directly translates into energy savings and reduced environmental impact due to less frequent replacement and maintenance.

Technical Specifications: Engineering Excellence for Viticulture

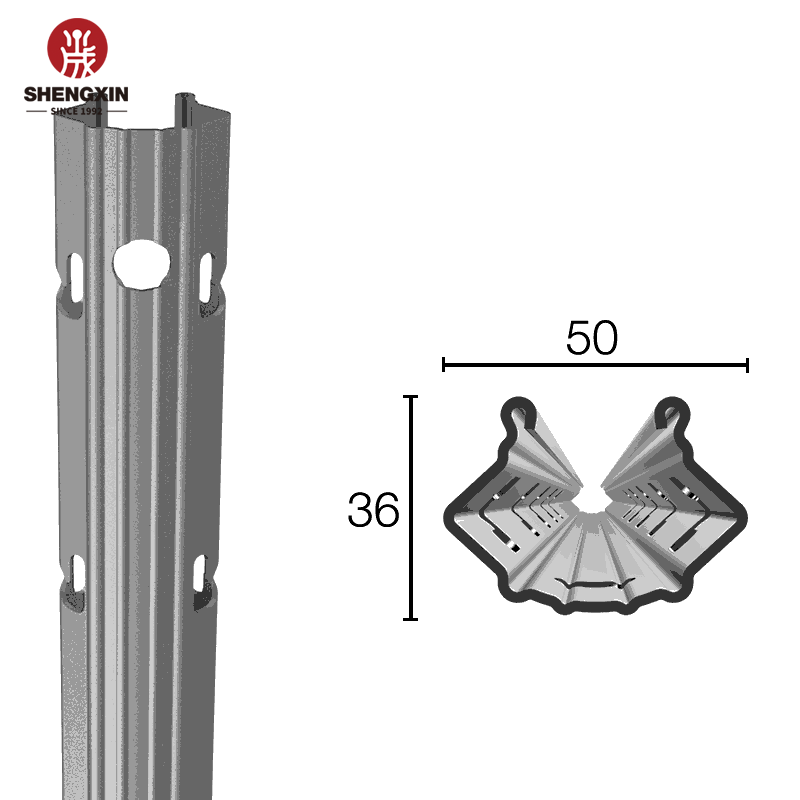

Understanding the technical parameters of the Galvanized Grape Vineyard Post Metal Pole Vineyard Trellis Post is crucial for vineyard planners and operators to select the optimal solution for their specific soil conditions, grape varietals, and trellising systems. The following table outlines typical specifications, highlighting the robust engineering behind these essential vineyard components.

| Parameter | Specification Range | Industry Standard/Note |

|---|---|---|

| Material Grade | Q235B, Q345B (Chinese Std) / S235JR, S355JR (EN) / ASTM A36 | High-tensile structural steel for strength and durability. |

| Surface Treatment | Hot-Dip Galvanized | As per ISO 1461 / ASTM A123 for superior corrosion resistance. |

| Zinc Coating Thickness | Typically 65-85 microns (450-600 g/m²) | Ensures 30+ years service life in most environments. |

| Profile Types | Y-post, U-post, C-post, V-post, Lyre Post | Varied designs to suit different trellising systems and load requirements. |

| Length | 1.8 m to 3.5 m (6 ft to 11.5 ft) | Customizable to specific vineyard topography and canopy management. |

| Thickness (Gauge) | 1.5 mm to 2.5 mm (16-12 Gauge) | Influences strength, weight, and cost. |

| Weight | 0.8 kg/m to 2.0 kg/m (Approximate, depending on profile/gauge) | Important for transport and installation logistics. |

| Hole/Hook Spacing | Typically 10 cm to 30 cm intervals | Optimized for various vine training systems (VSP, Scott Henry, Geneva Double Curtain). |

| Tensile Strength (Steel) | 340-500 MPa | Resistance to breaking under tension. |

| Yield Strength (Steel) | 235-345 MPa | Resistance to permanent deformation. |

These specifications underscore the posts' suitability for rigorous vineyard applications. The high tensile and yield strengths of the underlying steel, coupled with the protective hot-dip galvanization, ensure structural integrity and exceptional longevity, critical factors for long-term vineyard investments.

Application Scenarios and Technical Advantages

The versatility of the Galvanized Grape Vineyard Post Metal Pole Vineyard Trellis Post allows for its deployment across a multitude of vineyard settings and trellising architectures, delivering consistent performance and tangible benefits.

Typical Application Scenarios:

- Vertical Shoot Positioned (VSP) Systems: These are the most common trellising systems, where shoots are trained upwards. Metal posts with multiple wire slots are ideal for maintaining precise shoot positioning, optimizing sunlight exposure and air circulation, crucial for grape ripening and disease prevention.

- Guyot, Cane Pruning, and Cordon Systems: Whether utilizing single or double Guyot, or permanent cordon systems, the robustness of galvanized steel posts provides the necessary support for the vine's architecture and the weight of the developing canopy and fruit.

- High-Density Vineyards: In regions where land is at a premium, high-density plantings require reliable, compact, and durable trellising. The slim profile and superior strength of metal posts allow for closer spacing without compromising structural integrity.

- Mechanized Vineyards: For vineyards employing machine harvesting or pruning, the rigid and uniform structure provided by steel posts ensures smooth operation, reducing the risk of machinery damage and increasing efficiency.

- Organic and Sustainable Vineyards: By offering an exceptionally long service life and being fully recyclable at end-of-life, galvanized steel posts align perfectly with sustainable viticultural practices, reducing the carbon footprint associated with vineyard infrastructure.

Technical Advantages:

- Unmatched Corrosion Resistance: The hot-dip galvanization process creates a metallurgical bond, providing both barrier and cathodic protection. This dual defense system ensures the posts resist rust and degradation even in humid, acidic, or saline vineyard soils for over 30 years, significantly outperforming ungalvanized steel or treated wood.

- Superior Strength-to-Weight Ratio: High-tensile steel construction means these posts offer exceptional structural support for heavy canopies and fruit loads, enduring high wind loads and mechanical stresses more effectively than alternative materials.

- Ease of Installation and Maintenance: Their consistent dimensions and pre-punched holes simplify installation, reducing labor time and costs. The long service life minimizes the need for replacements, and the material's resistance to rot and pests reduces ongoing maintenance efforts.

- Fire Resistance: Unlike wooden posts, steel is non-combustible, offering a significant safety advantage in fire-prone regions.

- Environmental Sustainability: Steel is 100% recyclable, and the extended lifespan of galvanized posts reduces raw material consumption and waste. They also eliminate the need for chemical treatments often associated with wooden posts.

- Cost-Effectiveness Over Lifecycle: While initial investment might be slightly higher than some alternatives, the dramatically extended lifespan, reduced maintenance, and superior performance of these posts result in a significantly lower total cost of ownership (TCO) over the vineyard's operational life.

Vendor Comparison and Customized Solutions

Selecting the right supplier for Galvanized Grape Vineyard Post Metal Pole Vineyard Trellis Post products is as critical as choosing the product itself. Reputable vendors distinguish themselves through adherence to quality standards, capability for customization, and comprehensive customer support.

Key Considerations for Vendor Selection:

| Feature | Premium Vendor Offering | Typical Market Offering (for comparison) |

|---|---|---|

| Material Certification | Full traceability, Mill Certificates (e.g., EN 10204 3.1) for steel grade and composition. | Generic steel, no specific certification provided. |

| Galvanization Standard | ISO 1461, ASTM A123/A123M, AS/NZS 4680 with documented coating thickness reports. | "Galvanized" without specified standard or thickness, may be thinner or electro-galvanized. |

| Profile and Hole Accuracy | CNC-machined precision for all slots/holes, minimal burrs, consistent spacing. | Manual punching, inconsistent hole spacing, sharp edges. |

| Customization Options | Extensive options for length, gauge, profile, specific slot/hook designs, end caps. | Limited standard sizes only, no modification possible. |

| After-Sales Support | Technical consultation, installation guides, warranty, efficient claims process. | Minimal support, "as-is" sales. |

| Environmental Credentials | ISO 14001 certification, commitment to sustainable practices. | No specific environmental commitments. |

Our commitment to quality is underscored by ISO 9001 certification, ensuring consistent manufacturing processes and product excellence. We have partnered with leading vineyards globally for over 15 years, delivering reliable solutions tailored to diverse viticultural needs.

Customized Solutions for Unique Vineyard Requirements:

Recognizing that no two vineyards are identical, we offer extensive customization options for the Galvanized Grape Vineyard Post Metal Pole Vineyard Trellis Post to meet precise specifications:

- Length and Thickness: Posts can be manufactured in specific lengths (e.g., 2.1m, 2.4m, 2.7m, 3.0m) and gauges (e.g., 1.5mm, 1.8mm, 2.0mm, 2.2mm, 2.5mm) to match soil conditions, desired vine height, and expected canopy load.

- Profile Design: Beyond standard Y, U, or V profiles, custom profiles can be engineered for specialized trellising systems or unique load-bearing requirements.

- Hole and Hook Configurations: The number, spacing, and design of wire slots or hooks can be fully customized to accommodate various training systems (e.g., VSP, Geneva Double Curtain, Lyre systems) and allow for specific wire management strategies.

- End Treatment: Options include pointed ends for easier driving, flattened ends for surface installation, or specific anchor plate designs for enhanced stability.

- Additional Coatings: While hot-dip galvanization is standard, powder coating over galvanization can be provided for aesthetic requirements or additional chemical resistance in extremely corrosive environments.

Application Case Studies: Real-World Performance

The efficacy and long-term value of the Galvanized Grape Vineyard Post Metal Pole Vineyard Trellis Post are best illustrated through successful real-world deployments.

Case Study 1: High-Density Vineyard in Napa Valley, USA

Client: "Vineyard Estates" Winery, Napa Valley, California.

Challenge: Established vineyard sought to re-trellis 50 acres of premium Cabernet Sauvignon vines to a higher density VSP system. The previous wooden posts suffered from significant rot and required costly annual maintenance and replacement, particularly in the damp valley floor areas. The client required a solution with minimal disruption during installation, maximum longevity, and the ability to withstand high winds typical in the region.

Solution: We supplied 2.4-meter-long, 2.0mm gauge Y-profile hot-dip galvanized steel posts with custom-spaced wire slots to match their precise VSP architecture. A specialized hydraulic post driver was used for efficient installation, minimizing soil disturbance.

Results: Over five years post-installation, the vineyard reports zero post failures, minimal wire slippage, and a significant reduction in annual maintenance costs related to trellising. The enhanced structural integrity has improved canopy management, leading to better fruit quality and an estimated 15% increase in yield due to optimized sunlight exposure and reduced disease pressure. The winemaker noted, "These galvanized posts are a game-changer. Our previous wooden posts needed replacing every 7-10 years. We expect these to last for decades, providing a solid foundation for our future vintages."

Case Study 2: Coastal Vineyard in Marlborough, New Zealand

Client: "Ocean's Edge" Vineyard, Marlborough, New Zealand.

Challenge: A new vineyard development in a coastal region faced high salinity in the air and soil, posing a significant corrosion risk to standard metal components. The client also desired a system compatible with mechanical pre-pruners and harvesters, necessitating extreme post uniformity and durability.

Solution: We provided bespoke 2.7-meter, 2.2mm gauge C-profile hot-dip galvanized posts with an enhanced zinc coating thickness (averaging 80 microns) to combat the aggressive coastal environment. The C-profile was chosen for its superior rigidity and ease of wire management for machine operations.

Results: After three challenging seasons, including a severe coastal storm, the posts show no signs of corrosion or structural fatigue. The vineyard manager commented, "The investment in high-quality galvanized posts has paid off immensely. We've seen no issues with salt spray degradation, and their rigidity makes machine operations incredibly smooth, boosting our efficiency and reducing labor demands during critical periods. This level of trustworthiness is invaluable."

Trustworthiness: FAQ, Lead Time, Warranty & Support

Building trust with our B2B partners is paramount. We provide transparent information regarding our product, processes, and support commitments for the Galvanized Grape Vineyard Post Metal Pole Vineyard Trellis Post.

Frequently Asked Questions (FAQ):

- Q: What is the typical lifespan of your galvanized vineyard posts?

A: Our hot-dip galvanized posts, conforming to ASTM A123/ISO 1461, typically offer a service life exceeding 30 years in most agricultural environments, and often longer in less aggressive conditions. - Q: Are your posts suitable for organic vineyards?

A: Yes. Galvanized steel posts are an excellent choice for organic vineyards as they do not require chemical treatments (unlike some wooden posts) and are fully recyclable, aligning with sustainable and organic farming principles. - Q: How do your posts handle heavy snow loads or strong winds?

A: Engineered from high-tensile steel and designed with optimal profiles, our posts offer superior structural integrity to withstand significant snow loads and high wind forces, ensuring the stability of your trellis system. - Q: Can the wire slots/hooks be customized?

A: Absolutely. We offer extensive customization for hole patterns, sizes, and spacing to perfectly match your specific trellising system and vine training requirements.

Lead Time and Fulfillment:

Standard orders for our Galvanized Grape Vineyard Post Metal Pole Vineyard Trellis Post typically have a lead time of 4-6 weeks from order confirmation and deposit. Custom orders, depending on complexity and material availability, may require 6-8 weeks. We maintain robust logistics channels to ensure timely delivery worldwide, with capabilities for both containerized sea freight and expedited air cargo for urgent requirements. Detailed shipping schedules and tracking information are provided for all orders.

Warranty Commitments:

We stand behind the quality of our products. All galvanized vineyard posts come with a limited warranty covering manufacturing defects and premature corrosion that would impair the structural integrity or functional performance under normal usage conditions. Specific warranty periods and terms are detailed in our sales agreements and typically range from 10 to 20 years, depending on the product specifications and application environment, reflecting our confidence in our hot-dip galvanization process and steel quality.

Customer Support:

Our dedicated technical support team is available to assist with product selection, installation guidance, and any post-purchase inquiries. We provide comprehensive documentation, including detailed installation manuals and maintenance recommendations. For inquiries or support, please contact us via the details provided on our website. Our goal is to ensure a seamless experience from initial consultation to decades of reliable performance in your vineyard.

References

- American Society for Testing and Materials (ASTM). A123/A123M-17: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products. ASTM International, 2017.

- International Organization for Standardization (ISO). ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles—Specifications and test methods. ISO, 2022.

- Wine Institute. "California Wine Industry." Economic Impact Report, 2022. (Reflects regional industry data).

- Food and Agriculture Organization of the United Nations (FAO). "The State of the World's Land and Water Resources for Food and Agriculture (SOLAW)." FAO, 2021. (General agricultural context for material durability needs).

This is the last article

-

Galvanized Grape Vineyard Posts: Durable Metal Trellis Poles

NewsAug.26,2025

-

Durable Chain Link Fencing Wire - Secure & Quality Mesh Fences

NewsAug.25,2025

-

Durable 100% PVC Privacy Panels & Slats for Chain Link Fences

NewsAug.24,2025

-

Premium Galvanized Steel Fence Designs - Durable & Secure Panels

NewsAug.23,2025

-

ODM 7' Security Fence | 358 Anti-Climb Galvanized Panels

NewsAug.22,2025

-

3D Welded Wire Mesh Fence Panels with Peach Posts

NewsAug.21,2025